Viessmann B2HA 80 User manual

Other Viessmann Industrial Equipment manuals

Viessmann

Viessmann 8432 User manual

Viessmann

Viessmann 4519 User manual

Viessmann

Viessmann VITOBLOC 200 User manual

Viessmann

Viessmann Vitovalor PA2 User manual

Viessmann

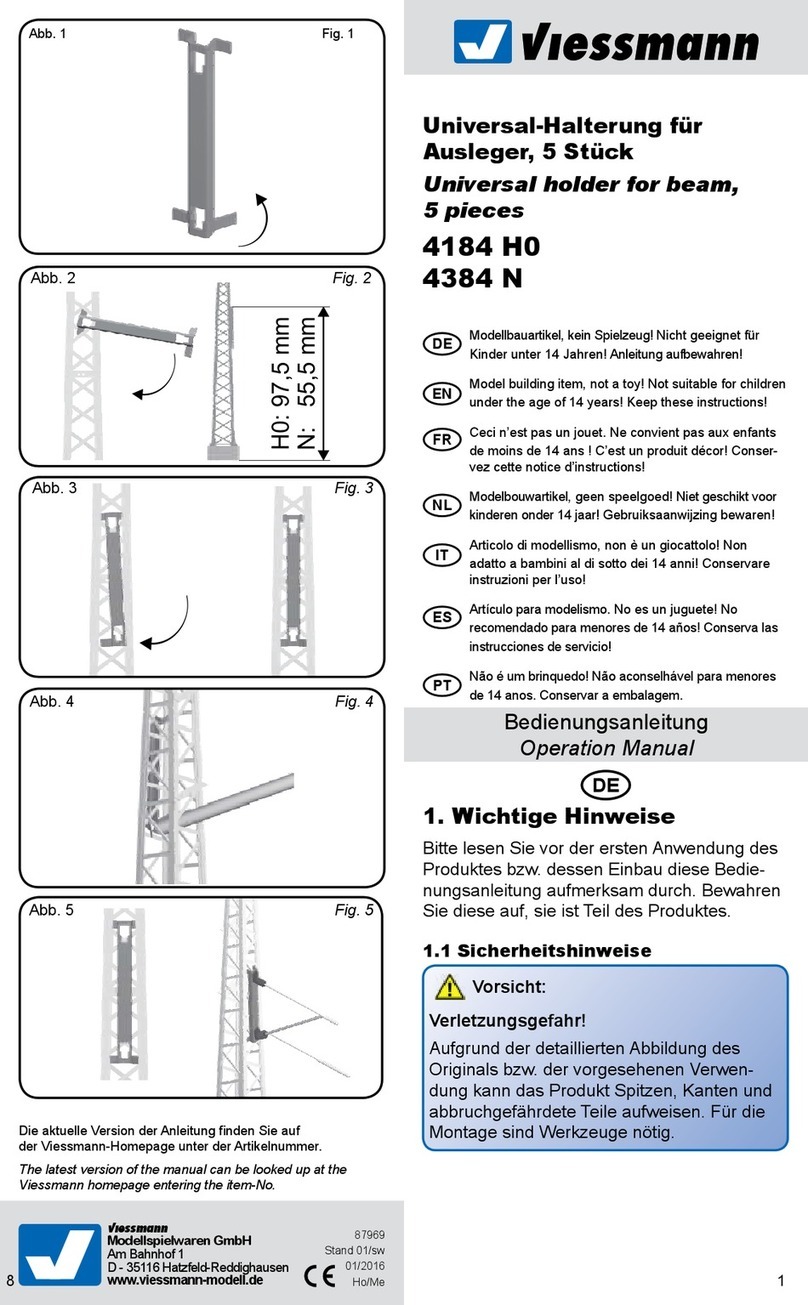

Viessmann 4184 H0 User manual

Viessmann

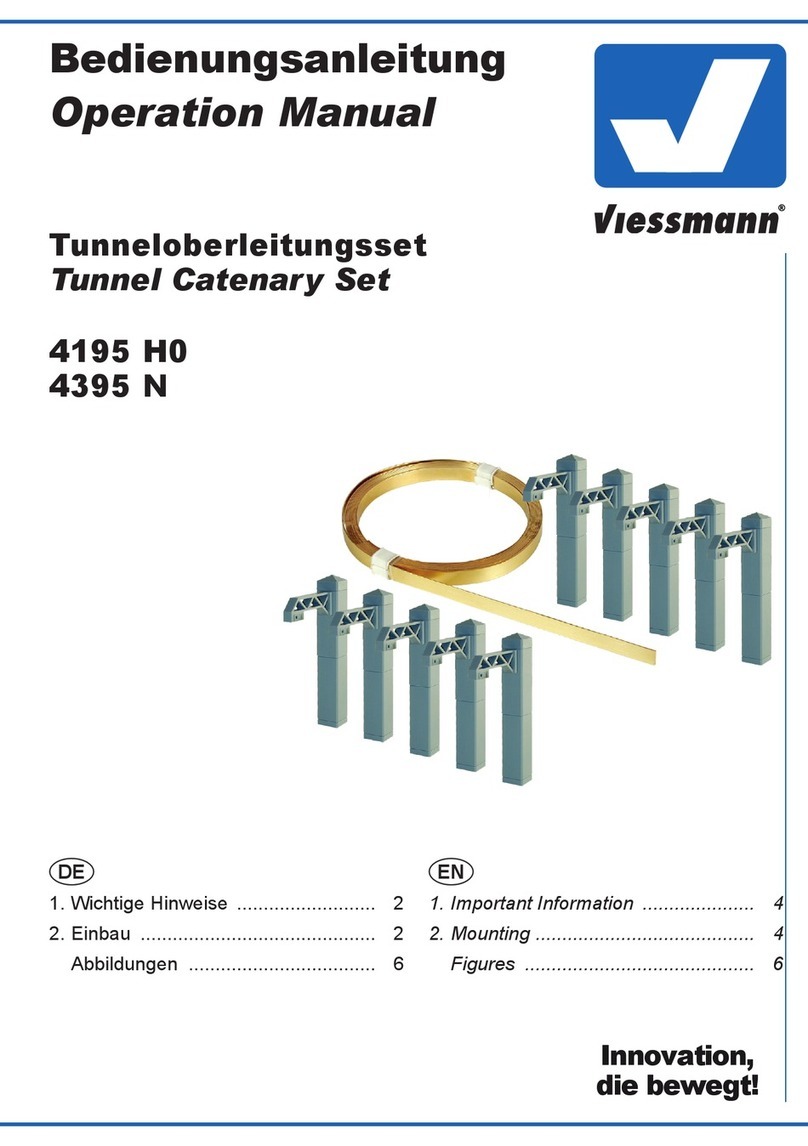

Viessmann 4195 H0 User manual

Viessmann

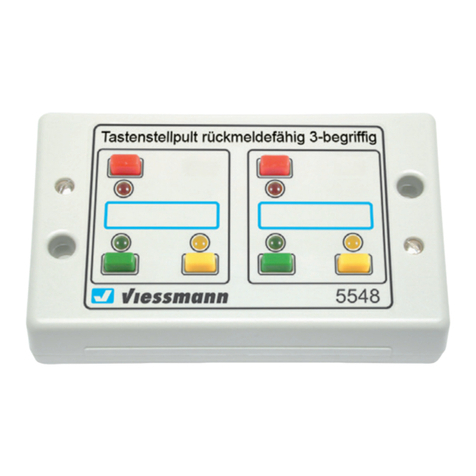

Viessmann 5548 User manual

Viessmann

Viessmann 4509 User manual

Viessmann

Viessmann VITOBLOC 200 Parts list manual

Viessmann

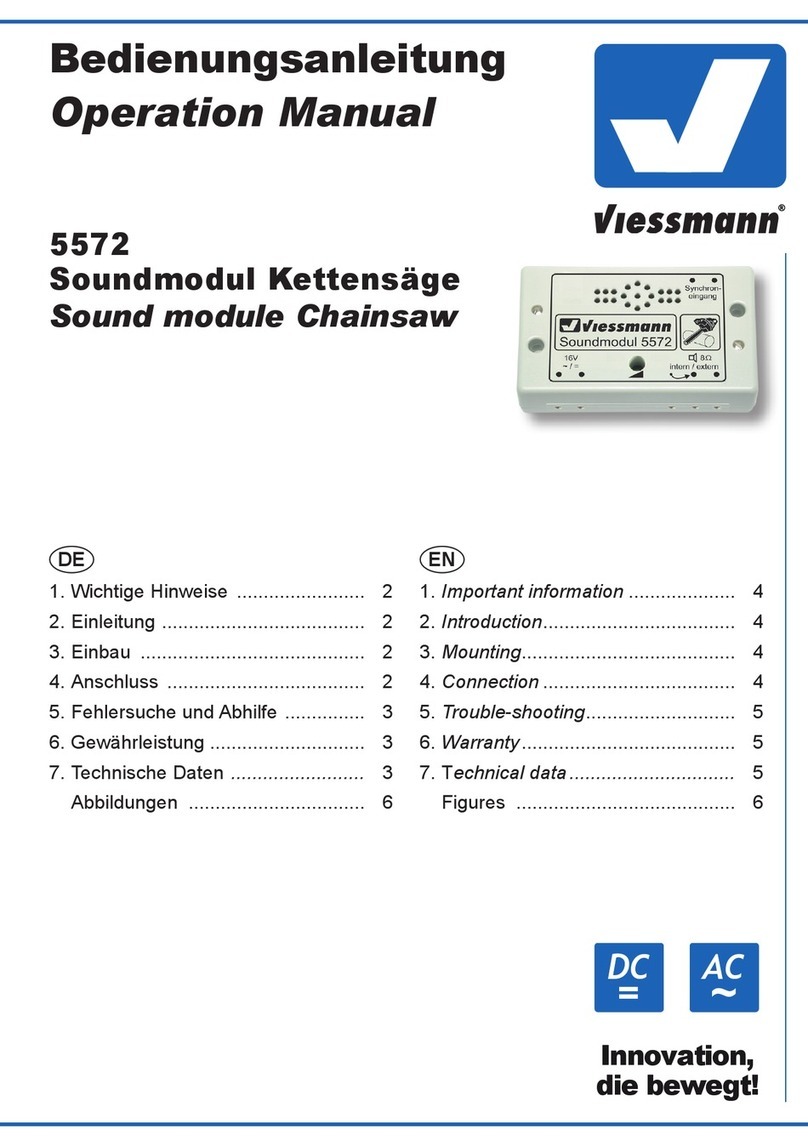

Viessmann 5572 User manual

Viessmann

Viessmann VITOBLOC 200 User manual

Viessmann

Viessmann 5071 User manual

Viessmann

Viessmann N Spanbridge User manual

Viessmann

Viessmann EM-S1 Quick guide

Viessmann

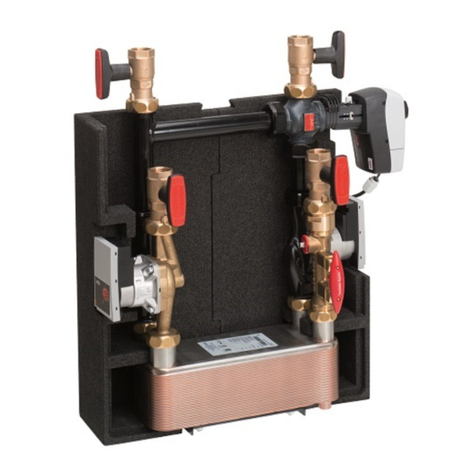

Viessmann VITOTRANS 222 Operating instructions

Viessmann

Viessmann vitotronic 200-h User manual

Viessmann

Viessmann S3HA Series Service manual

Viessmann

Viessmann Sub Mounting Kit User manual

Viessmann

Viessmann 1969 User manual

Viessmann

Viessmann Vitogate 300 Operating instructions