Page No. 3-GB 1 - 2.3 We reserve the right to make technical changes!

1. Description

The units are designed for the prescribed temperature

anges. If they are operated outside the prescribed tempe-

rature range for several days, the possibility of a serious

defect on the refrigerating unit cannot be discounted.

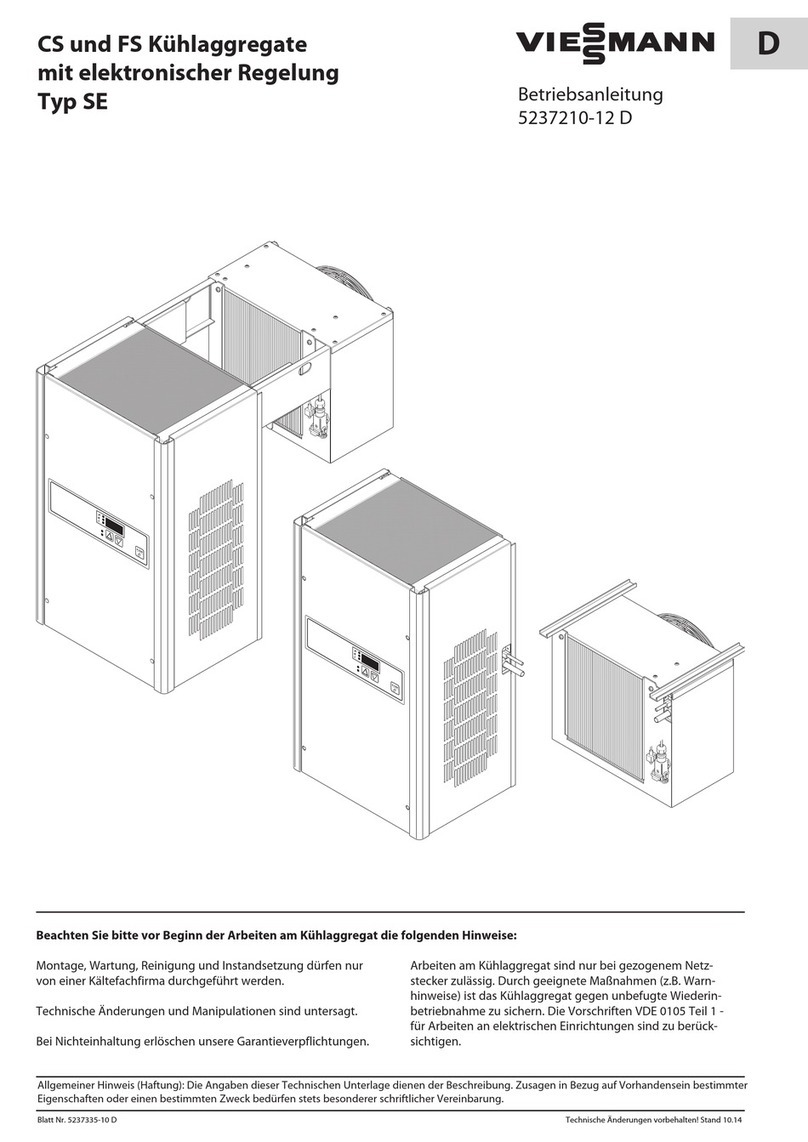

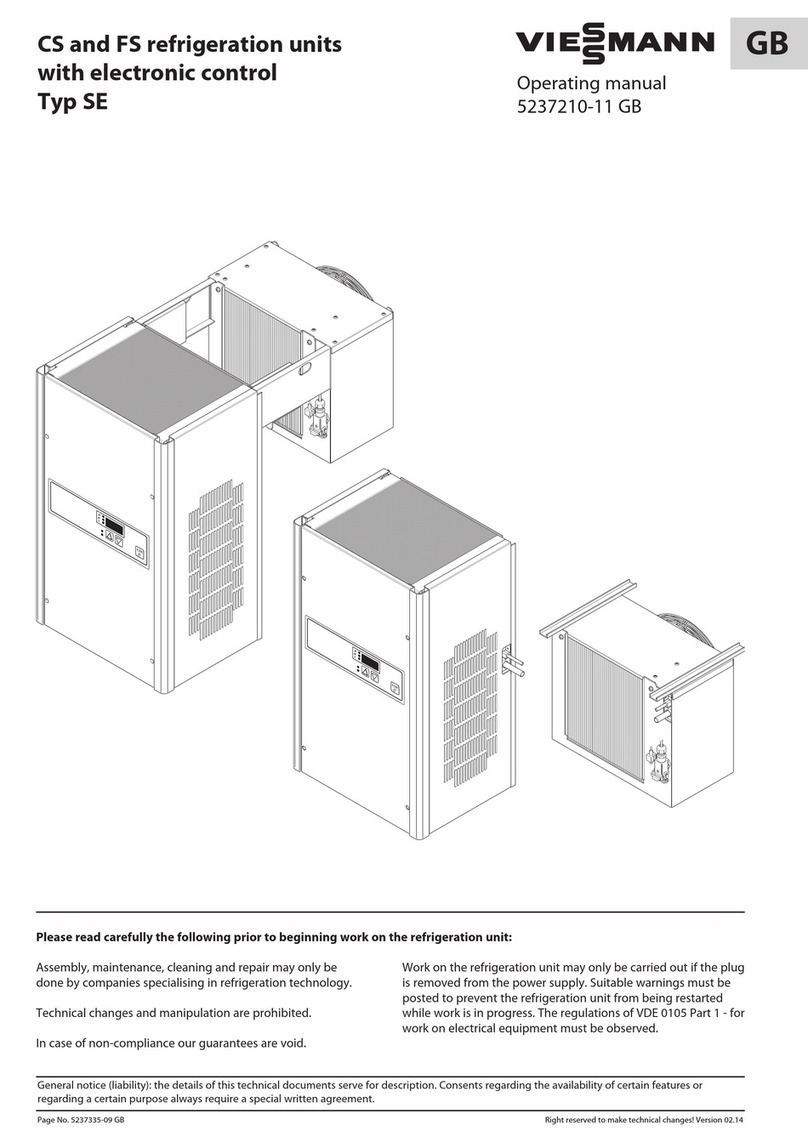

1.1 Deep-freeze unit

FS 0900, FS 1200, FS 1400, FS 1800, FS 2400

The units are designed for the cooling of rooms, in which

goods are stored at temperatures of -25°C to -1°C.

1.2 Refrigeration unit

CS 0500, CS 0900, CS 1300, CS 2000, CS 2800

The units are designed for the cooling of rooms, in which

goods are stored at temperatures of -5°C to +19°C.

2. General information

2.1 Excepts from our Warranty conditions

The warranty is valid for 1 year. The period of entitlement

begins on the day of delivery, which must be verified by

the Bill of delivery or Invoice. Within the period of warran-

ty, functional defects attributed to faulty design or materi-

al defect will be rectified at no charge.

Claims in excess of these, in particular those related to

consequential damage, are excluded.

We will accept no liability for damages, which result from

improper or unauthorised utilisation, faulty installation

or commissioning on the part of the customer or a third-

party, natural wear and tear, faulty or negligent handling,

chemical, electro-chemical or electrical influences, as long

as the fault cannot be attributed back to actions taken

on our part, non- compliance with Installation, Operating

and Maintenance Instructions, improper modifications or

repair work on the part of the customer or a third-party,

as well as the influence of replacement parts from third-

party origin.

Warranty entitlement is forfeited, as well, if the refrigera-

tion circuit has been opened by unauthorised personnel,

access has been made to the system assembly, or the

serial number has been changed or made unrecognisa-

ble.

2.2 Standards and regulations

The Wall-hanging unit has been built and inspected

according to the standards and regulations valid at the

time of manufacture.

It complies with the

EMC Directive 2004/108/EC,

machinery directive 2006/42/EG.

The unit has been inspected at the factory for refrigerati-

on circulation leakage and for function.

2.3 Requirements for installation area / Intended use

The Refrigeration unit must not be assembled outdoors.

The Refrigeration unit must be setup to ensure the free

intake and discharge of air. In the event the use of air

ducts is unavoidable, project planning must be made by

a refrigeration specialist company.

Sufficient free space must be provided for in front of

the Refrigeration unit intake and discharge openings in

order to warrant a good air flow:

- minimum 250 mm in front of all intake and

exhaust openings

If it is not possible to maintain this clearance, then suf-

ficient air flow must be warranted by means of suitable

measures (air deflector, air ducts, additional ventilators).

The unit must not be deployed in areas where strong

strong magnetic interfering impulses are anticipated or

in the vicinity of transmitting antennas.

The unit must not be setup in an explosive atmosphere!