ENGLISH

1. Before you start

1.1. Warranty

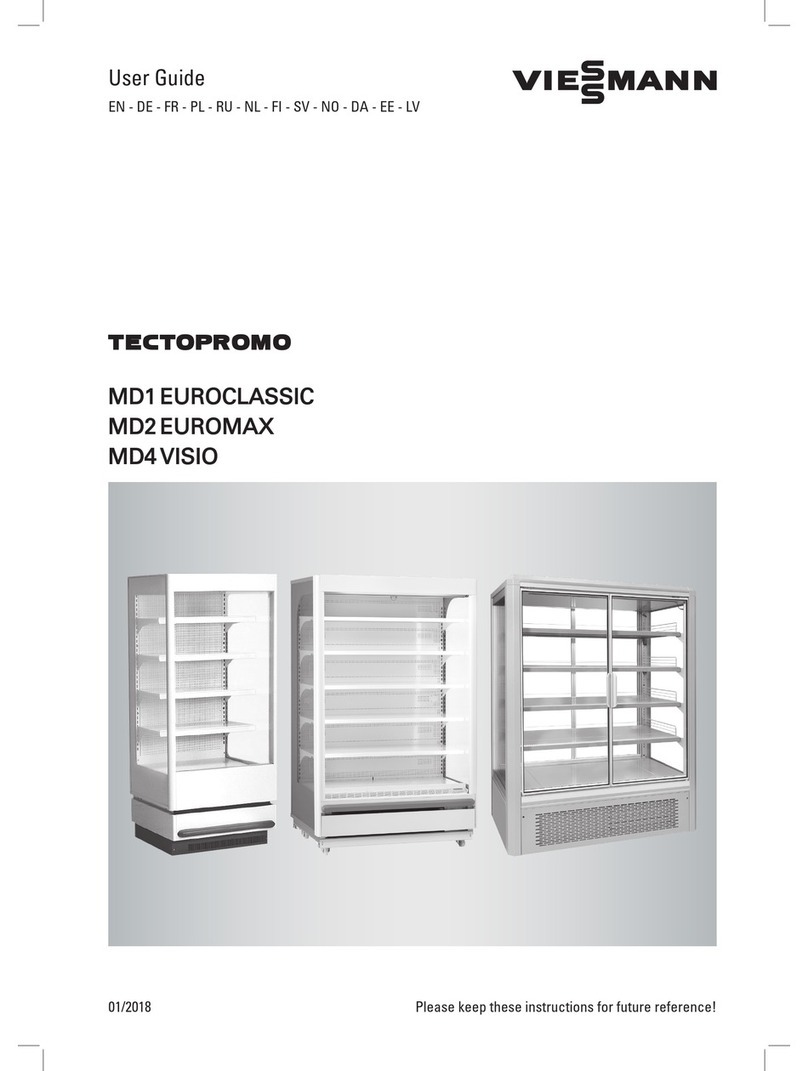

2. EcoCooler / EasyCooler / Rollo

2.1. Warnings

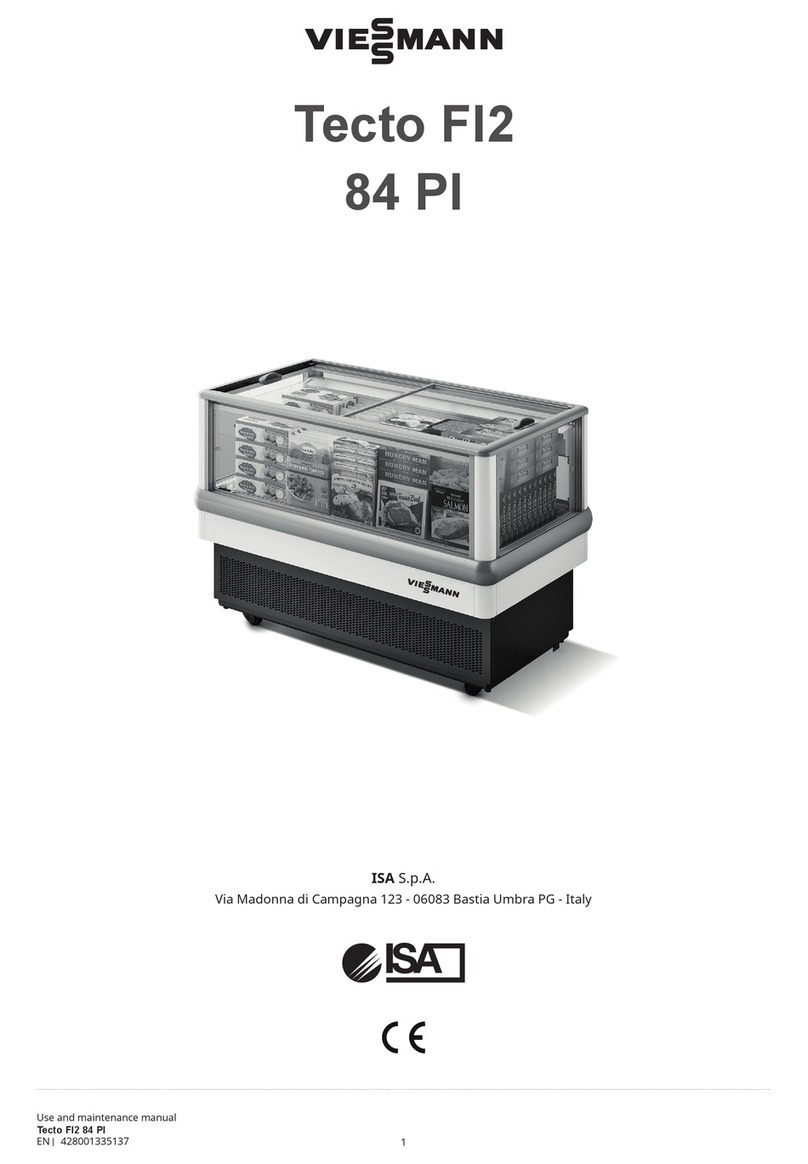

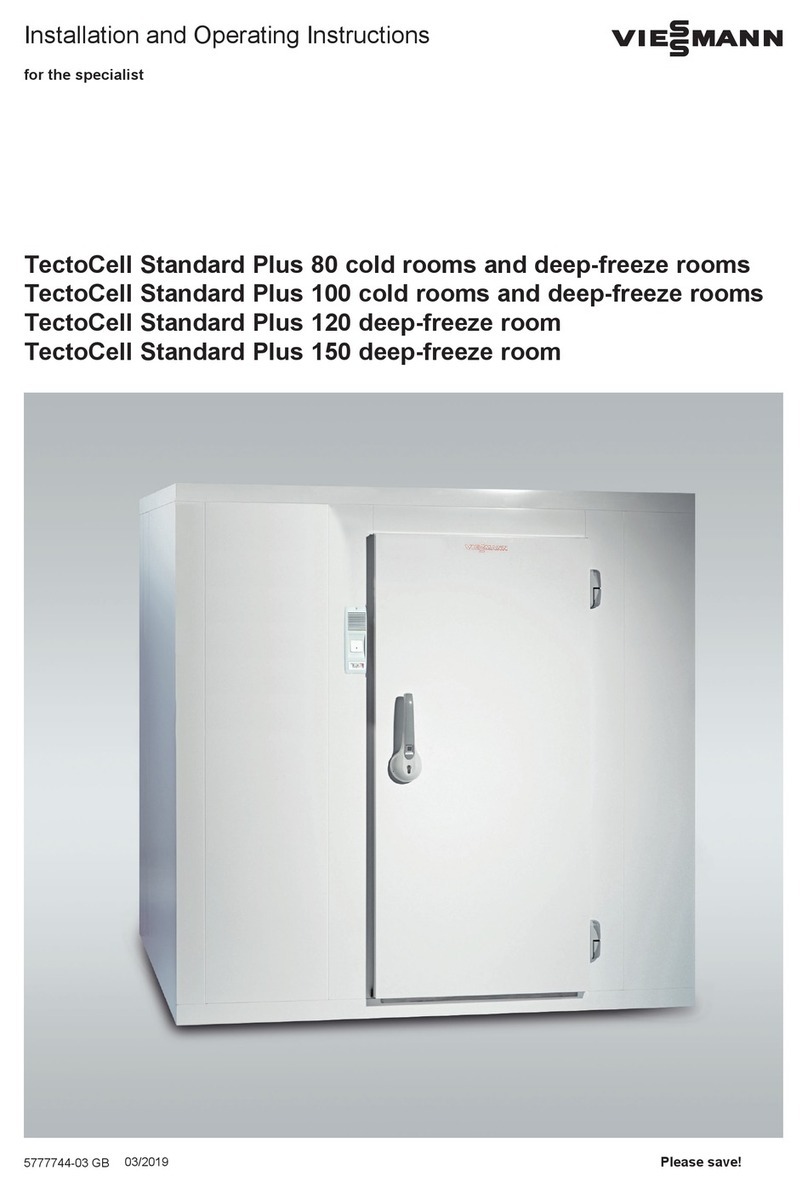

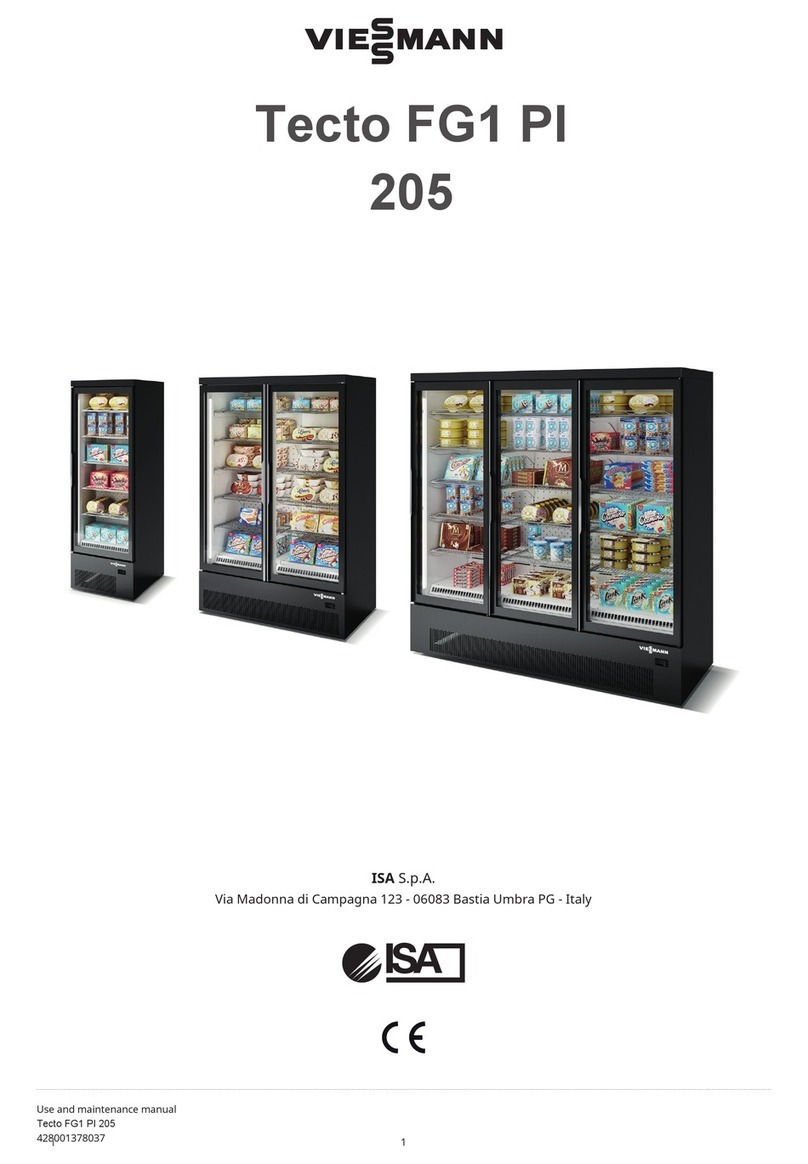

2.2. Cabinet types

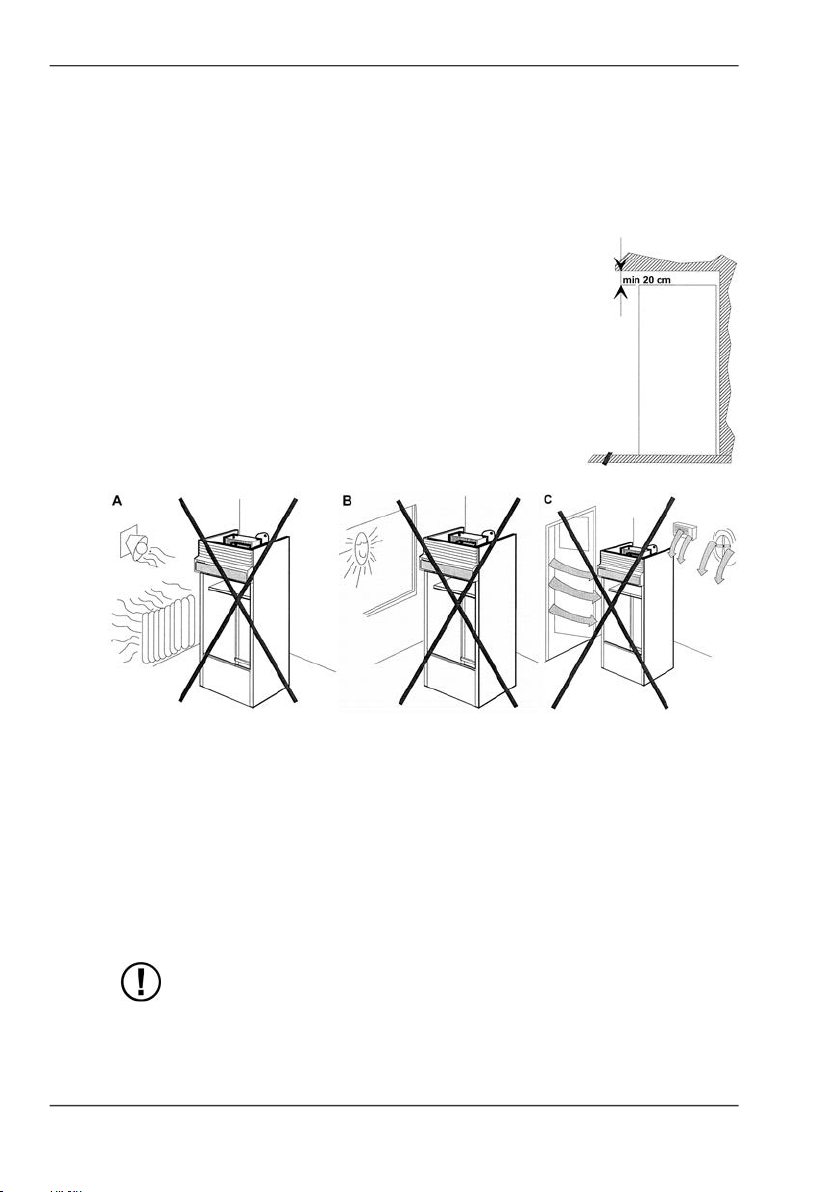

2.3. Restrictions

2.4. Package

2.5. Transport damage

2.6. Installing

2.7. Cleaning before use

3. Electrical connections

4. Operation

4.1. Starting up

4.2. Loading cabinet

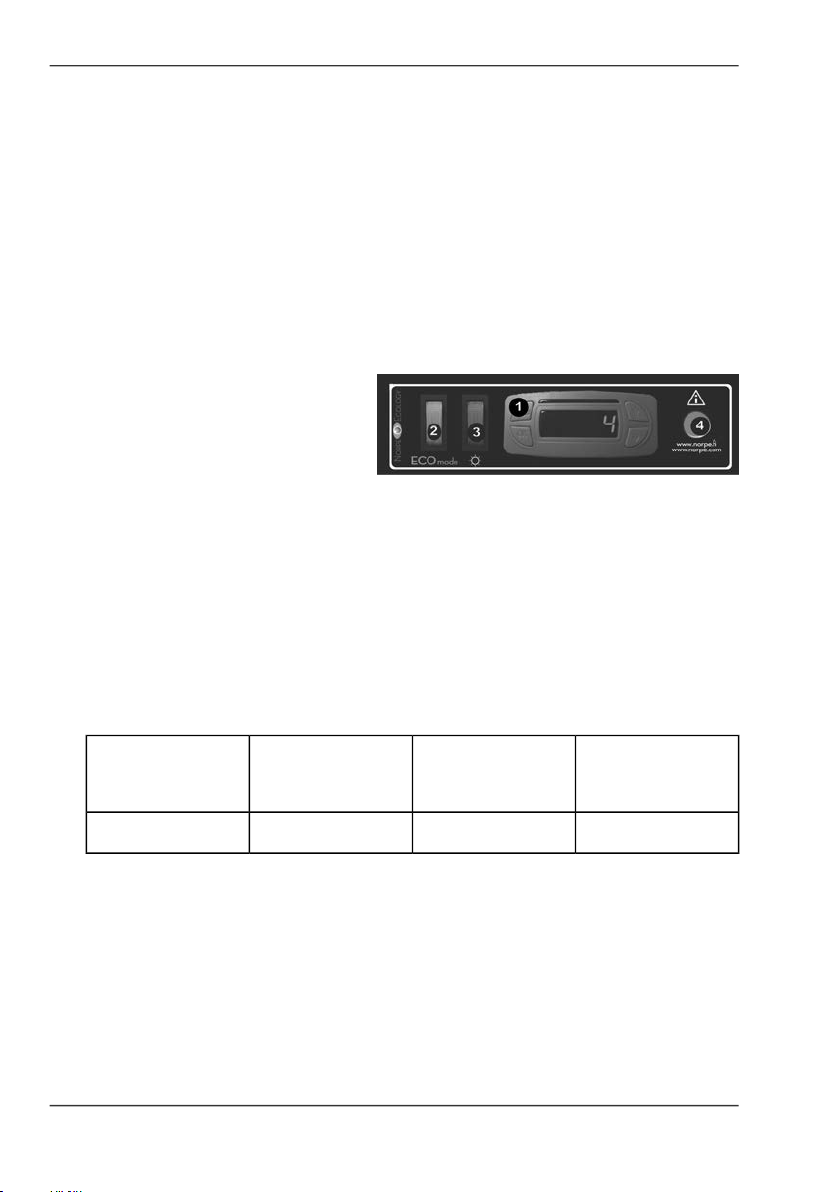

4.3. EcoCooler user interface

4.4. Setting operating thermostat

4.5. Control devices

4.6. NRC-100 control device

4.7. Dixell XR40CX control device

4.8. Automatic defrosting

5. Cleaning

5.1. Cleaning condenser

6. Interruptions in electricity distribution

7. Troubleshooting

8. Servicing and spare parts

9. Disposal of equipment

ENGLISH