TS21I_IR_CO2 User Manual

Vighnaharta Technologies Pvt Ltd Page 9 of 13

1008 %v/v Higher 16-bit

100 %v/v Lower 16-bit

4 3 1002/2 Read Threshold Low

3 1003/3 Read Threshold High

5 4 1002/2 Read Threshold Low

4 1003/3 Read Threshold High

6 5 101 Write D02 High Alarm

5 102 write D01 Low Alarm

7 6 1002 Write Threshold Low

6 1003 Write Threshold High

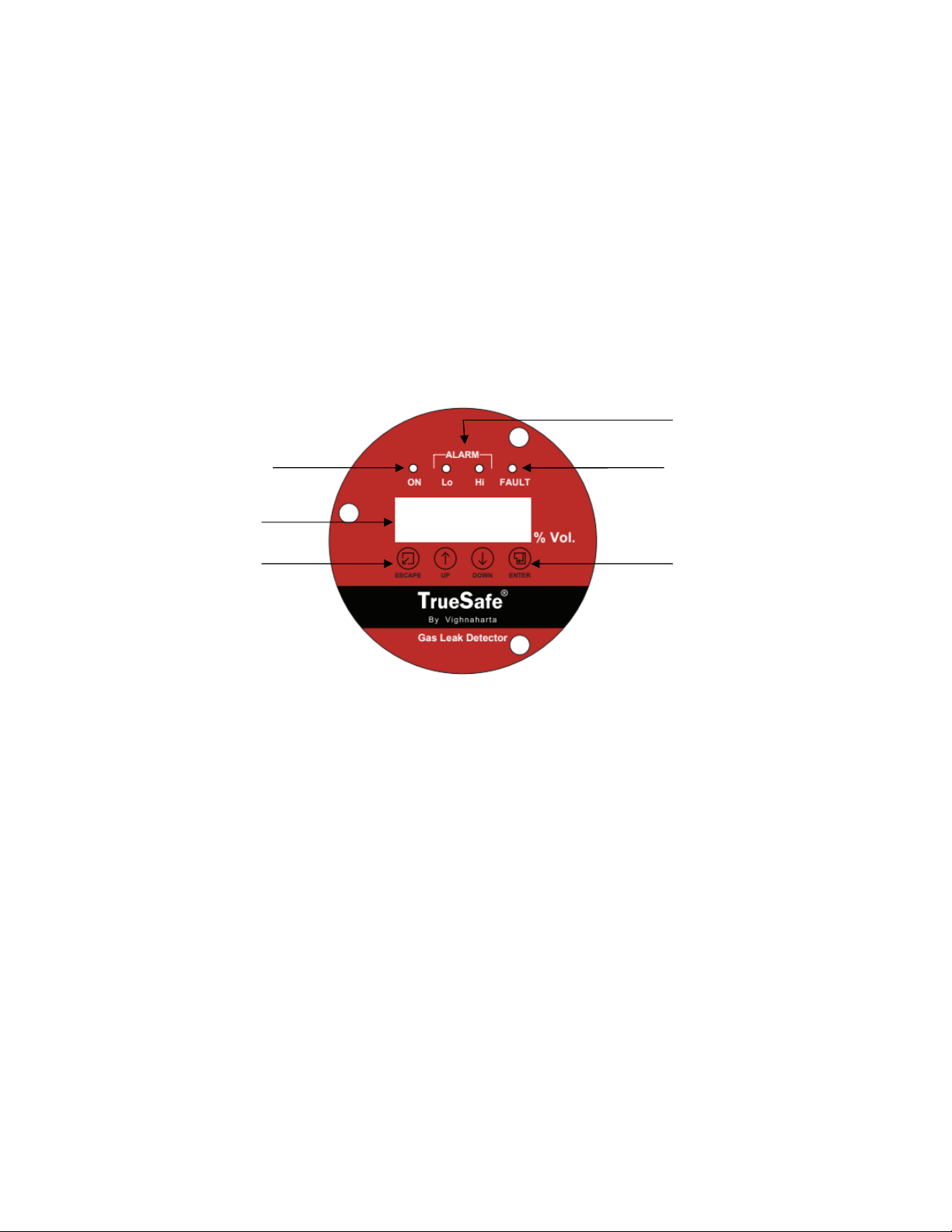

Understanding controls on front panel

LE Indicators

1. ON Power ON LED. Green LED turns on when power is ON. It

indicates Power On status of the unit.

When gas concentration exceeds low threshold level,

TS21I_IR_CO2 generates low alarm condition. For low alarm

condition, yellow LED turns ON till unit is reset.If relay1 output

is pulse type, relay remains on for 5sec. If relay1 output is

latch type, relay remains on till the unit is reset.

3. H- Alarm When gas concentration exceeds high threshold level,

TS21I_IR_CO2 generates high alarm condition. For high alarm

condition, red LED turns ON till unit is reset. If relay2 output is

pulse type, relay remains on for 5sec. If relay2 output is latch

type, relay remains on till the unit is reset.

3. F- Alarm When supplay goes below 1 V or above 2 V and also sensor

status open or short. Orange LED turns ON till unit is reset. If

relay3 output is pulse type, relay remains on for 5sec. If

relay3 output is latch type, relay remains on till the unit is

reset.

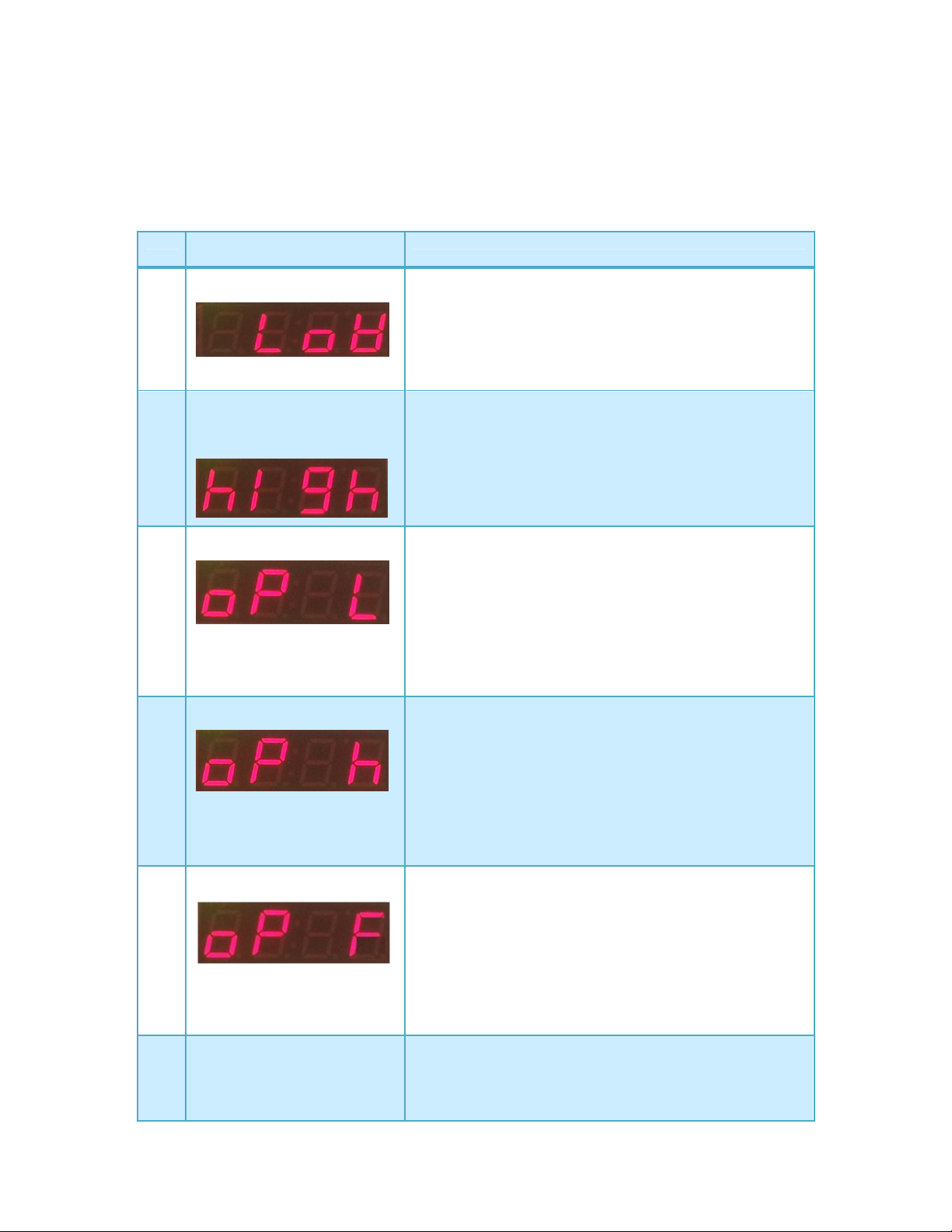

gas concentration in %v/v. Also it shows configuration settings

like current / voltage range.

Example, the seven segments LED display shows the 0.046

%v/vof gas concentration.

Magnetic Keypad - Four magnetic keys operate using magnetic stylus.

1.

ENTER Move stylus to ENTER key to enter into system to access

menus. This key has dual function. It is used to Enter or Save

the data. User can select some menu or can save settings

made by the user. If user presses the key during Idle mode, it

displays the menu.

2. ESCAPE Move stylus to ESCAPE key to exit from the current menu. If

user exits without saving, current settings will not be saved.

key to move menu up side or increment the

menu.

4. OWN Move stylus to OWN key to move menu down side or

decrement the menu.

0 .0 4 6