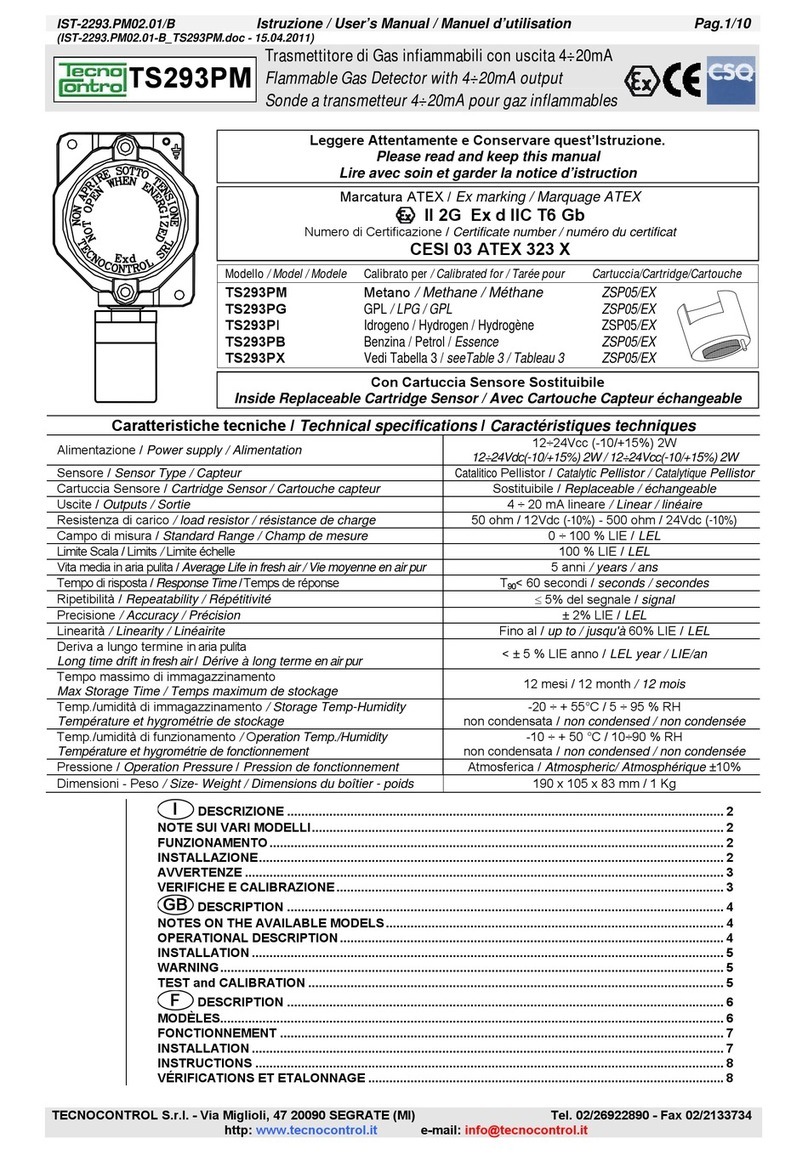

SE330KM Methane Neg.

SE330KG L.P.G.Neg.

SE333KM Methane Pos.

SE333KG L.P.G.Pos.

INSTALLATION INSTRUCTIONS

Use a screwdriver to undo the screw on the right-hand side of the

instrument and lift the cover (Fig 1).

Position the base correctly and fasten it on the built-in 3-module box or on

the wall, using the screws and dowels provided.

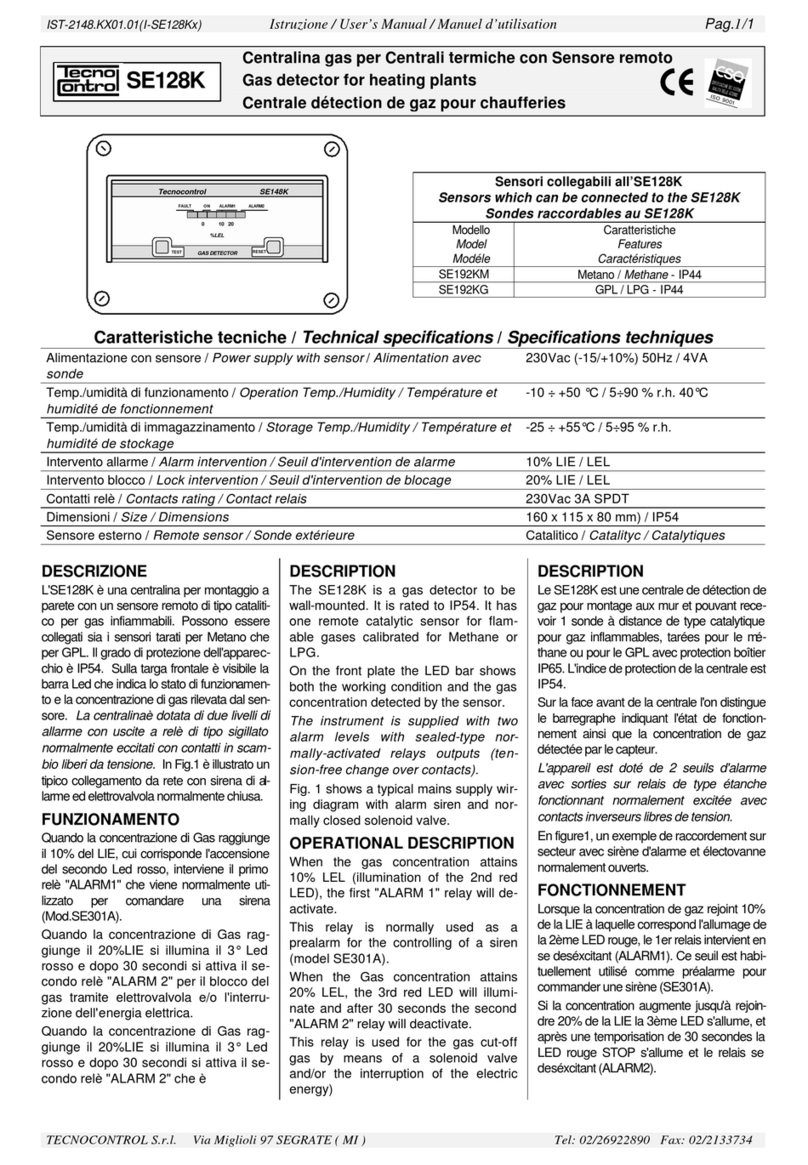

GENERAL DESCRIPTION

The Beta SE330K and SE333K gas detectors are methane or LPG control

units with LEDs and a buzzer that warn of the presence of gas in the

room. They are designed to be operated either directly or in remote mode.

The Beta detectors are calibrated to detect gas at 10% of the LEL (Lower

Explosive Limit); this threshold can vary according to environmental

conditions but will not exceed 15% of the LEL within the first five years of

use. The Sensor module must be replaced at the end of these five years or

if the “FAULT” LED turns on.

There is a label on the cover that should state the expiry date (5 years

after the date of installation); this label must be compiled by the person

who installs the detector, at the time of installation.

LEDS AND BUZZER

There are three LEDs on the front of each detector:

- GREEN LED (ON): indicates the instrument is powered.

- YELLOW LED (FAULT) + BUZZER: Indicates the sensor is broken.

- YELLOW LED (FAULT) blinking only: indicates the CO sensor

needs to be replaced.

- RED LED (ALARM): indicates the concentration of gas in the

air is above the alarm threshold.

If the gas sensor is defective, the buzzer will make a noise at a rate of

every two seconds, turning on the yellow LED and relay output.

In the event of an alarm, the red LED turns on and the buzzer and relay are

activated twenty seconds later.

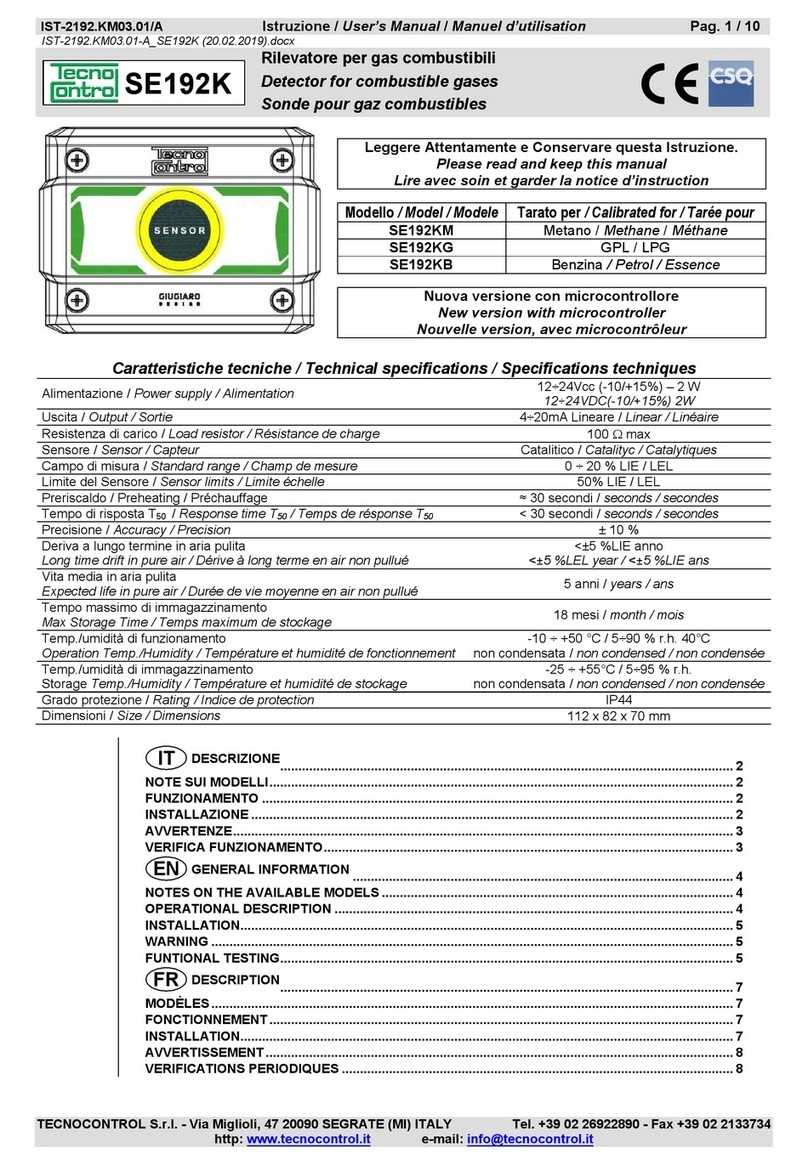

1-4m

30cm

max

L.P.G. gas

detector.

30cm

max

1-4m

Methane gas

detector

ELECTRICAL CONNECTION: POWER SUPPLY

Attention: undertrack cables are required to connect the instrument to the

mains.

The gas detector must be powered at 230 Vac using terminals 1 and 2, or

at 12Vdc using terminals 3 (+) and 4 (-). (Fig. 2).

A circuit breaker must be fitted that is able to disconnect the detector from

the power supply, with a contact distance of at least 3 mm, in accordance

with the European standard IEC EN 60335-1.

Fig.1

INSTALLING THE INSTRUMENT

The instrument MUST BE INSTALLED:

- In the case of Beta SE330KM and Beta SE333KM methane gas detectors,

series Beta model SE330K

series Beta model SE333K

GAS LEAK DETECTOR FOR DOMESTIC USE WITH

INTERCHANGEABLE SENSOR

GENERAL TERMS OF THE GUARANTEE

THIS CERTIFICATE IS THE ONLYDOCUMENT THAT ENTITLES

YOU TO REPAIR OF THE PRODUCT UNDER THE TERMS OF

THE GUARANTEE.

- The product is GUARANTEED for a period of 24 months from the date

of purchase.

- The GUARANTEE does not cover damage caused by tampering,

incorrect or improper use and installation.

- The GUARANTEE is valid only if it is duly compiled.

- In the event of defects covered by the GUARANTEE, the manufacturer

will repair or substitute the product free of charge.

SERVICINGAFTERTHE GUARANTEE PERIOD:

Any repairs after the period of the GUARANTEE will be charged on the

basis of the parts substituted and the cost of labour.

Model Detected gas Logic Power supply

230Vac 50Hz /

12Vdc

12Vdc

230Vac + -

1 2 4

3

Fig.2

at a maximum distance of 30 cm from the ceiling; in the case of Beta

SE330KG and Beta SE333KG LPG gas detectors, at a maximum height of

30 cm above the floor.

- At a distance of between 1 and 4 metres from the gas appliance (cooker,

boiler, etc.). If possible, in every room where there is a gas appliance and,

in the case of multi-storey buildings, at least one on each floor.

CHARACTERISTICS OF THE OUTPUT SIGNAL

The Beta SE330K and SE333K control units have an output relay with

voltage-free contacts; the rating of the contacts is 8A 250Vac/30Vdc.

Sensor module

ZSDM1 METHANE SE330KM/SE333KM

ZSDG1

L.P.G.SE330KG/SE333KG

Detected gas

Code Beta

LIGHTING DELAYS

After the detector is turned on, the catalytic sensor in the detector takes

about a minute to warm up, during which time the green LED blinks to

indicate the alarm is disabled.

INSTALLATION

Attention: the instrument must be installed and put out of service by a

specialized technician.

Your gas supply and any shut-off devices must be installed in conformity

with the domestic laws in force.

The instrument MUST NOT BE INSTALLED:

- Directly above the sink or gas appliance.

- In small rooms where alcohol, ammonia, spray cylinders or other

substances based on volatile solvents might be used.

- In closed environments or corners where there is no free circulation of

air.

- Near walls or other obstacles that could prevent the flow of gas from the

appliance to the detector, or extractors and fans that could divert the flow

of air.

- In environments where the temperature could exceed 40°C or fall below

– 5°C.