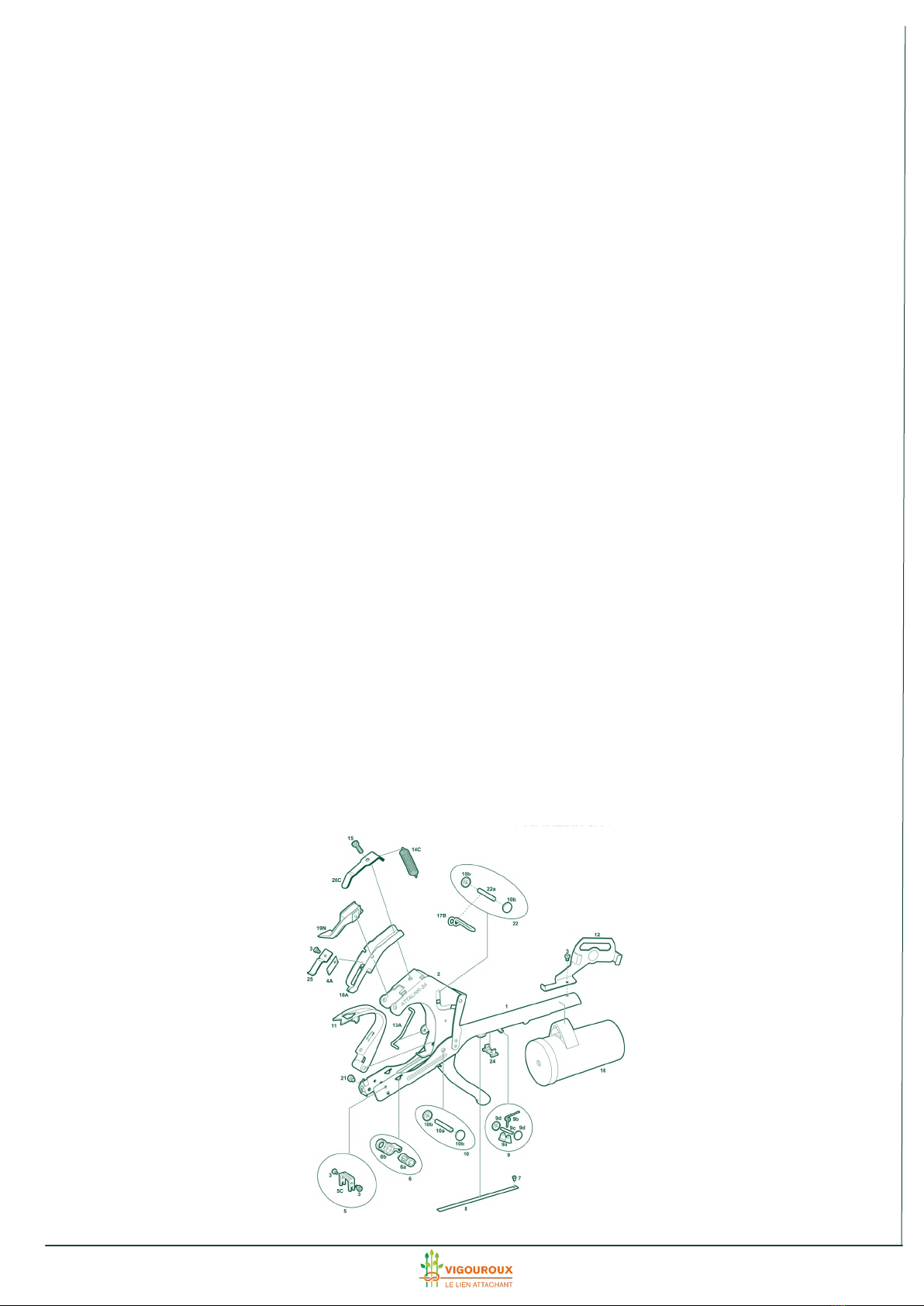

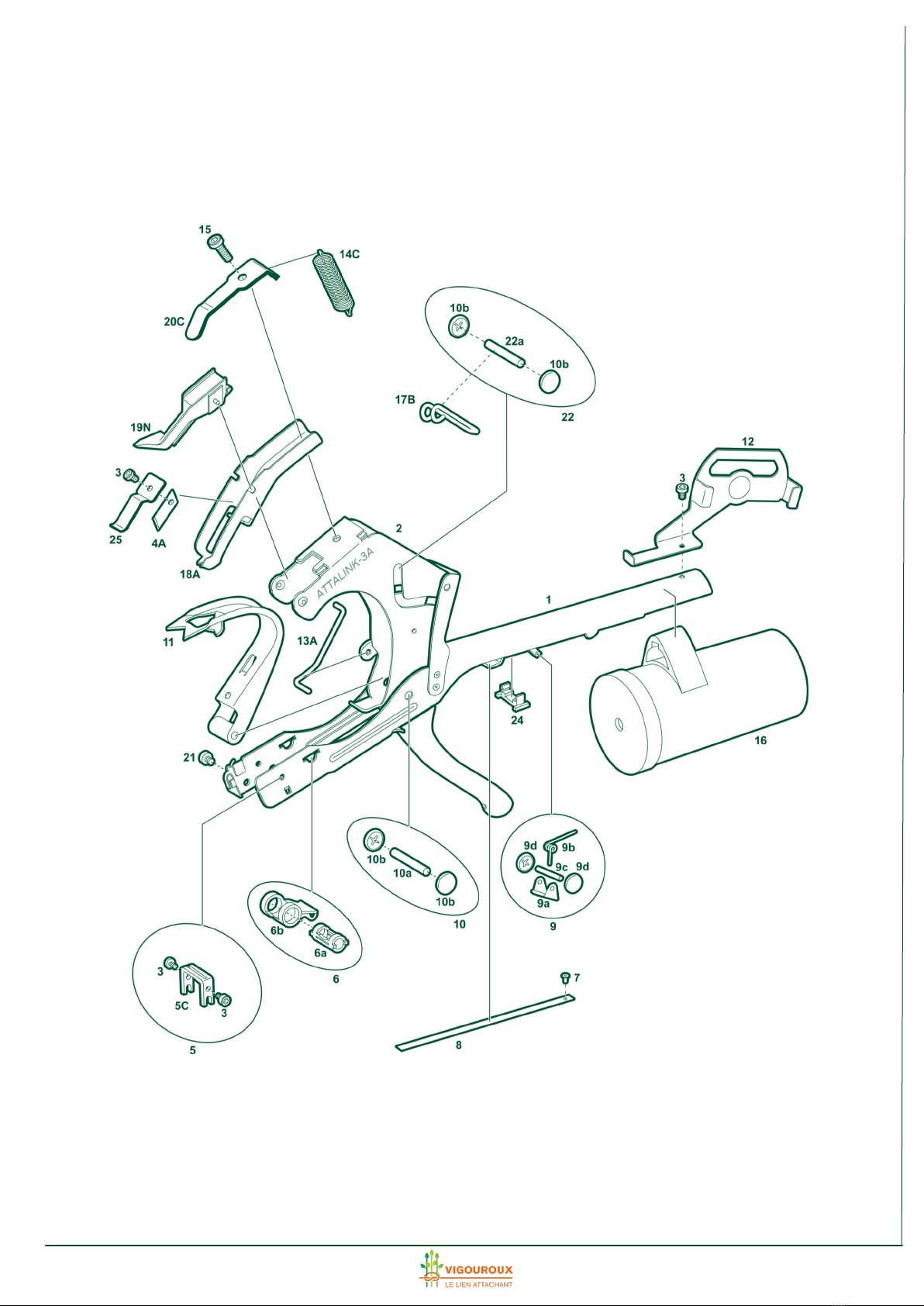

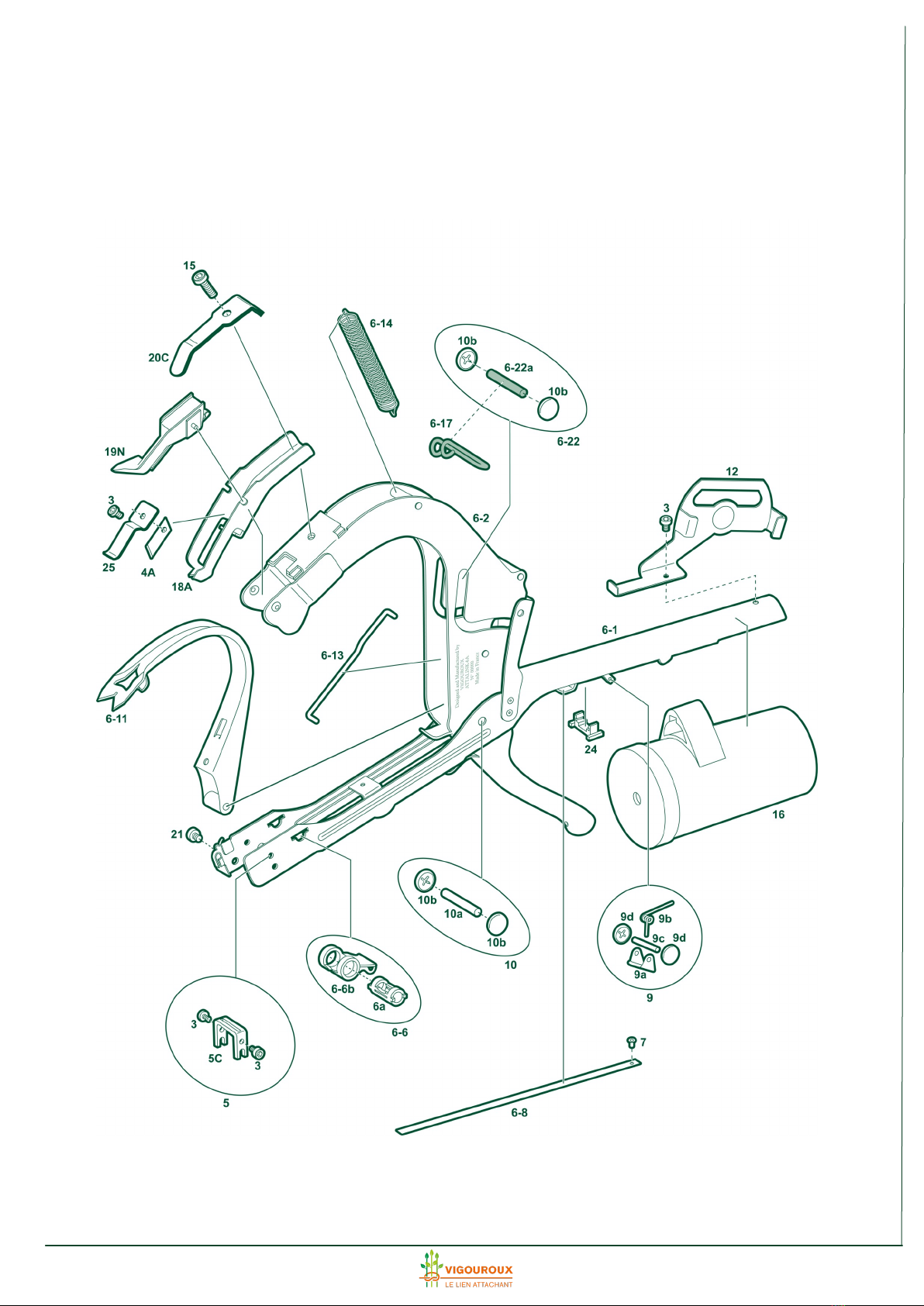

5

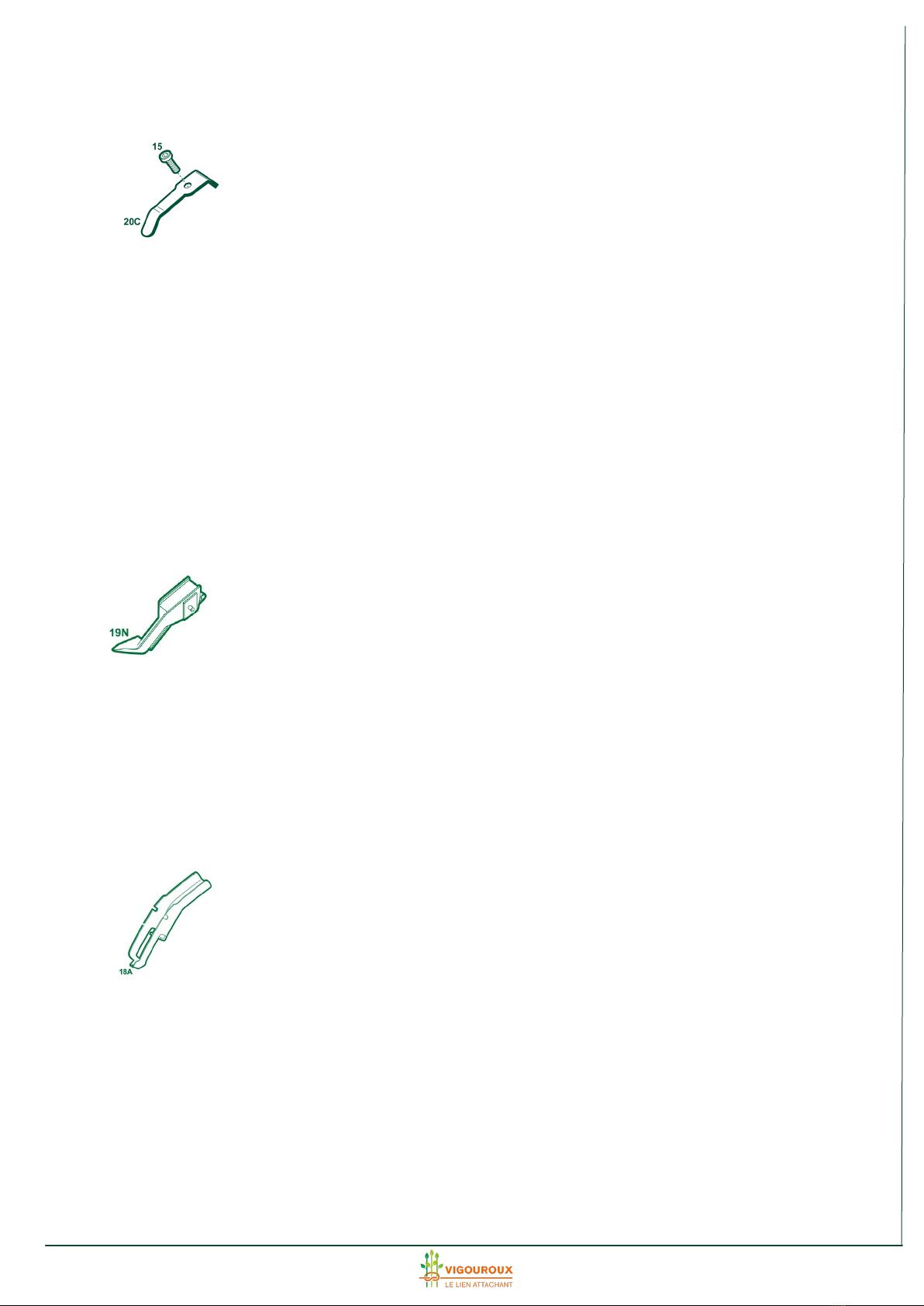

Part n°20C –Strip spring holding the thread blocking device (part n°19N)

This part allows the thread blocking device to actuate when the

ATTALINK tying tool opens and repositions it opposite the thread feed

eye (in part n°1).

The shape of the strip spring, which pushes against the thread blocking de-

vice (part n°19N) is important: it stabilises the thread blocking device and

gives it enough freedom to move upwards and downwards to perform its

function.

The tension of this spring has an effect on overall performance of the tool:

- not enough tension: the thread blocking device (part n°19N) may trigger

due to the tension of the thread when the object to be tied is introduced. If

this happens, it snags against the thread feed eye or passes underneath the

eye and fails to release the cut thread,

- too much tension: the thread blocking causes too much friction, thereby

preventing the tying tool from opening again.

Please refer to the adjustment and part changing manual, paragraph VII, § 4

(photo 28).

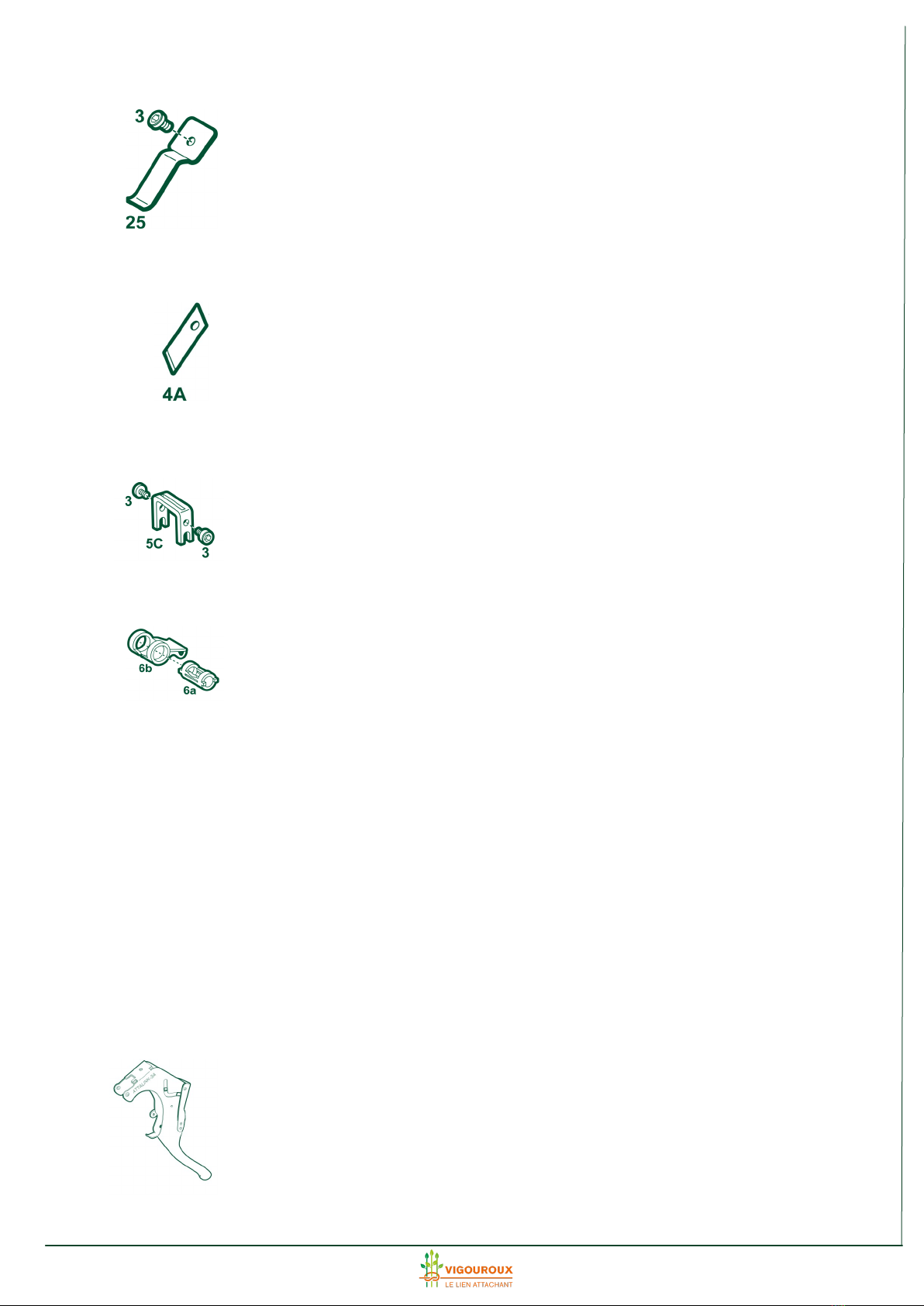

Part n°19N –Complete thread blocking device

This part consists of a metal and a plastic part hinged to a pin and held in

position by a spring.

The thread blocking device catches the thread and keeps it blocked for the

time it takes to apply the tie, and then releases it.

The shape of the metal part gripping the thread is crucial for smooth opera-

tion of the entire system:

- it grips the thread as it leaves the feed eye

- it effectively blocks the thread

Refer to the adjustment manual, paragraph VII.

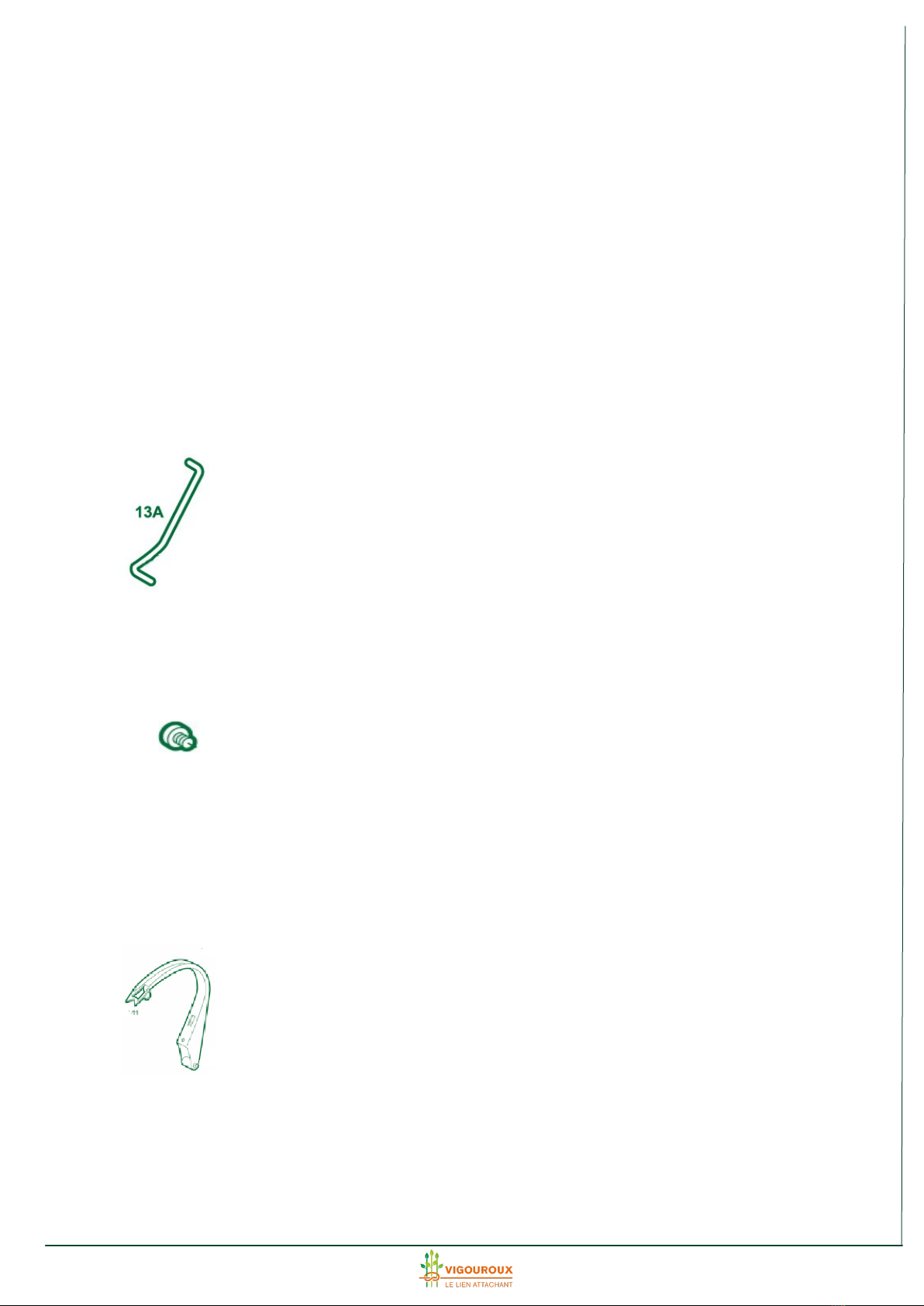

Part n°18A –Thread blade support casing

- Aligns the thread blade (part n°4A) with the thread cutter (part nº 5C) so

that the blade travels through the slits in the thread cutter.

- Acts as an end-of-travel stop for the hand tool: the two tabs on either side

of the blade provide an end-of-travel stop for the handle when closing.

Adjustment:

Following an impact, it may be necessary to realign the blade (part n°4) and

the cutting device (part n°5). To do this, use leverage on part n°18A to bend

it back in the right direction.

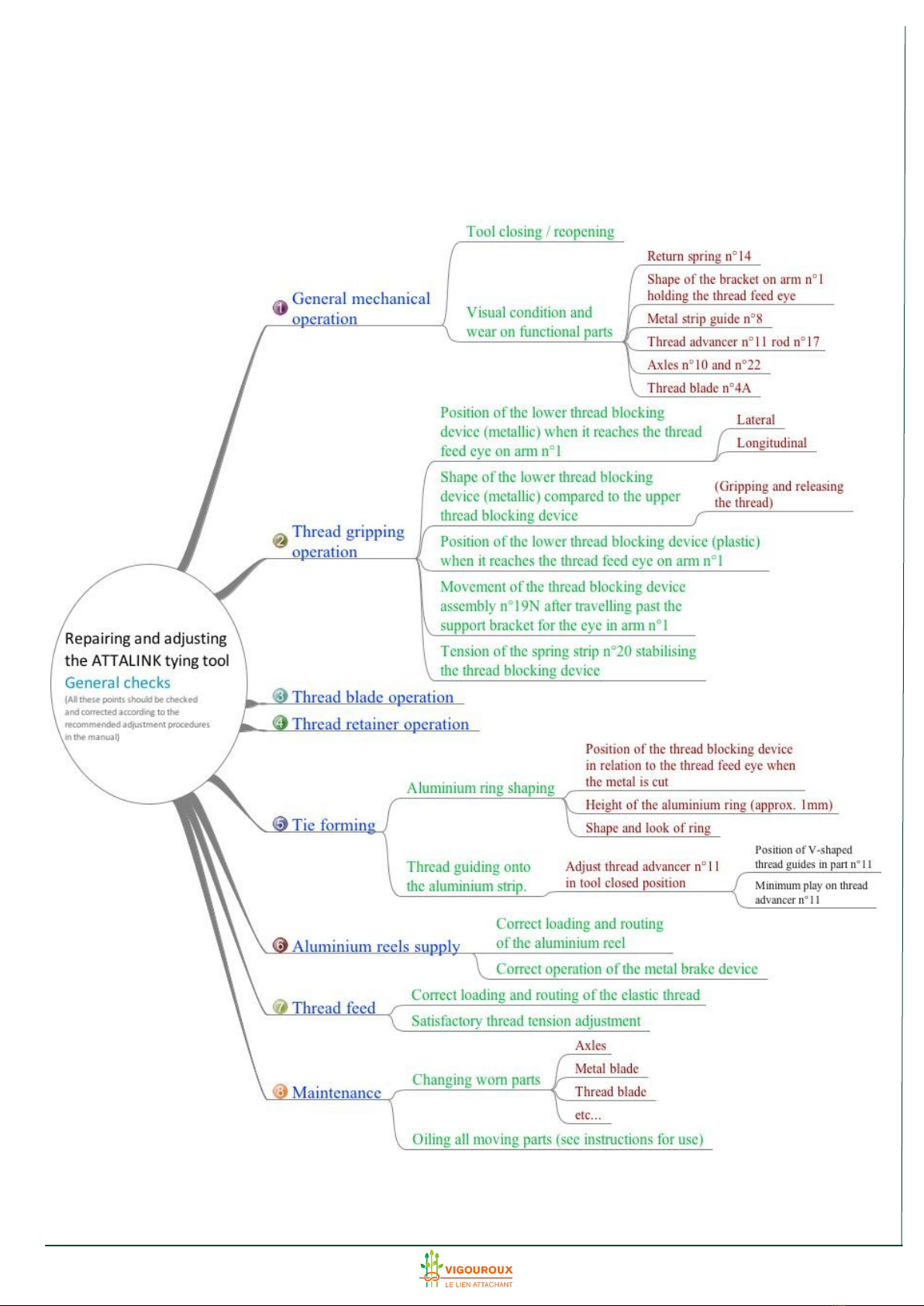

DETAILED VIEW OF PARTS