TABLE OF CONTENTS

Frame

Axles

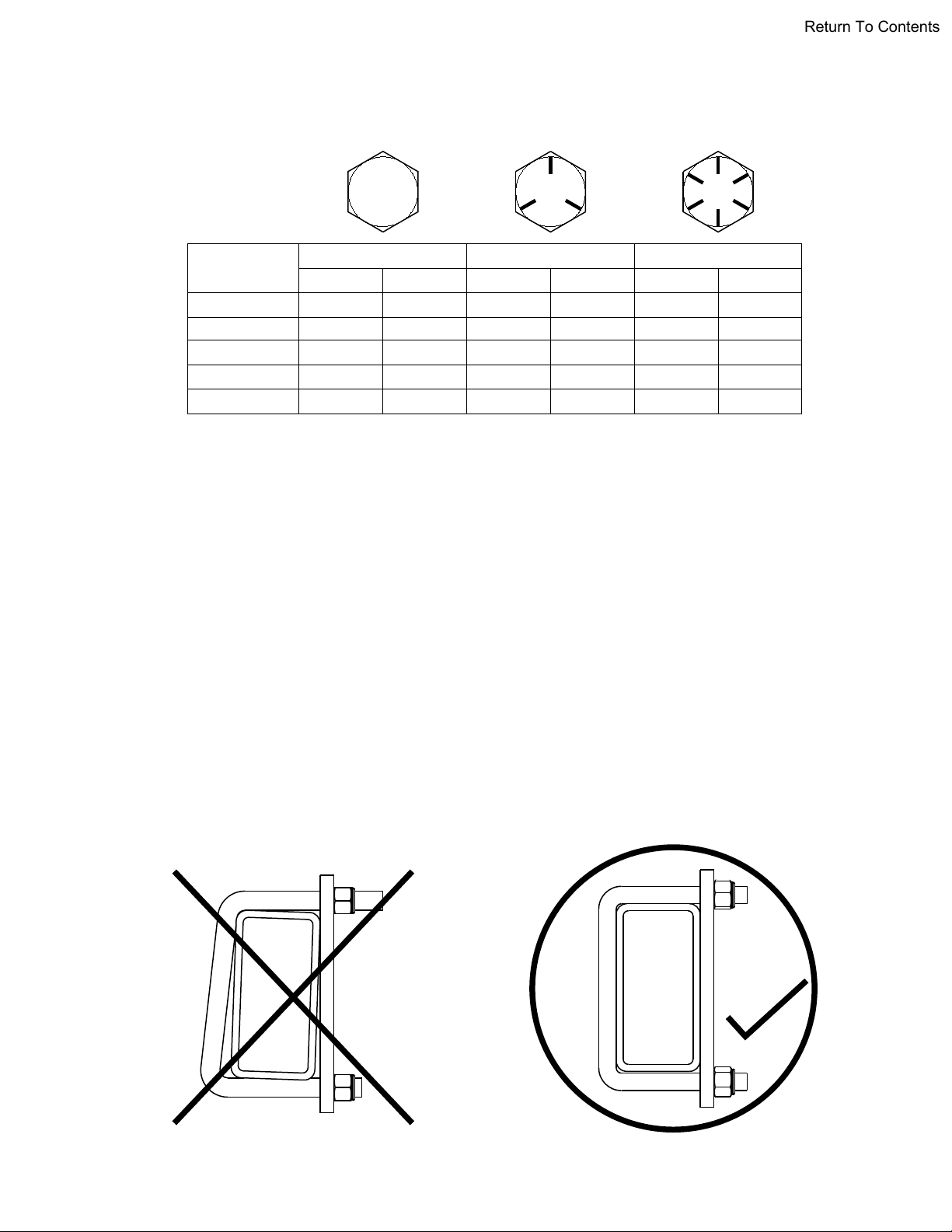

Torque Recommendations & U-bolt Instructions..........................................1

General Safety Precautions .........................................................................2

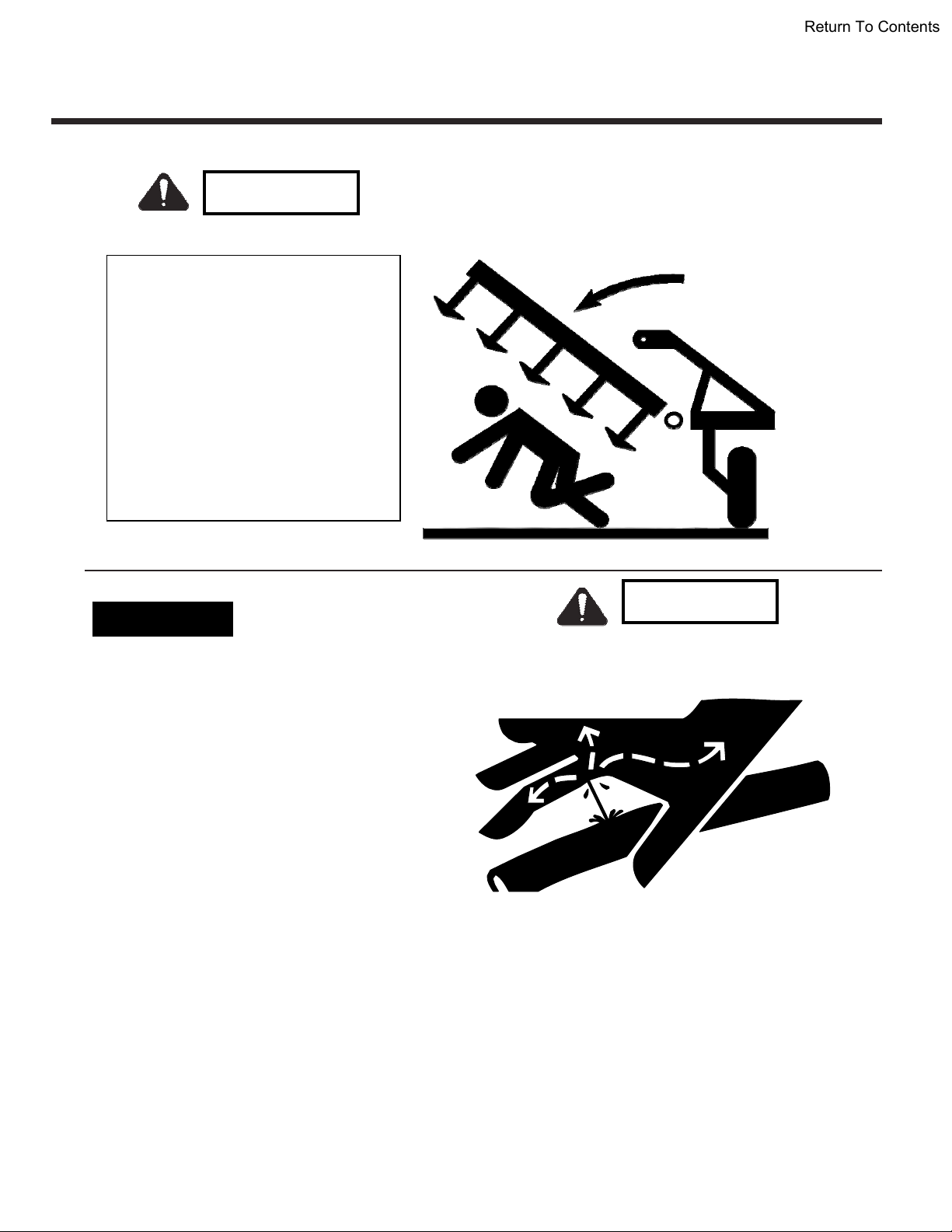

Safety Decal Locations............................................................................... 4

Frame Assembly ..........................................................................................6

Wing Fold Cylinder Installation.....................................................................8

Fifth Bar Installation.................................................................................. 10

Self leveling & Depth Control Installation ................................................... 12

Tongue installation ..................................................................................... 14

24ft, 27ft & 30ft Axle Layout ....................................................................... 16

41ft Axle Layout ........................................................................................ 17

8000lb Main Frame Axle Installation (24ft, 27ft, 30ft) ................................ 18

10000lb Main Frame Axle Installation (41ft)............................................... 20

8000lb Axle Assembly (24ft, 27ft, 30ft) ...................................................... 22

10000lb Axle Assembly (41ft) .................................................................... 24

5000lb Wing Frame Axle Installation (24ft – 41ft) ...................................... 26

5000lb Axle Assembly (24ft – 41ft) ........................................................... 28

5000lb Hub & Spindle Assembly ................................................................ 30

4000lb Hub & Spindle Assembly .............................................................. 32

8000lb Hub & Spindle Assembly............................................................... 34

Coulter Assembly

RTS Coulter & Mount Parts .......................................................................36

Coil-Tech Hub ............................................................................................ 38

Harrow Assembly

Harrow Setup ............................................................................................40

Tine Performance Settings ........................................................................41

62” Arm Assembly...................................................................................... 42

½” Tine Harrow Assembly .........................................................................44

14” Roller Assembly ..................................................................................46

Coulter & Harrow Layouts

13ft Coulter & Harrow Layout ....................................................................48

24ft Coulter & Harrow Layout ....................................................................50

27ft Coulter & Harrow Layout ....................................................................52

30ft Coulter & Harrow Layout ....................................................................54

41ft Coulter & Harrow Layout ....................................................................56

Hydraulics & Lights

Wing Fold Hydraulics ................................................................................. 58

Axle Lift Hydraulics....................................................................................60

Lights and Slow Moving Vehicle Sign ........................................................ 62

Transport Lock ........................................................................................... 65

Grease Bank .............................................................................................. 66