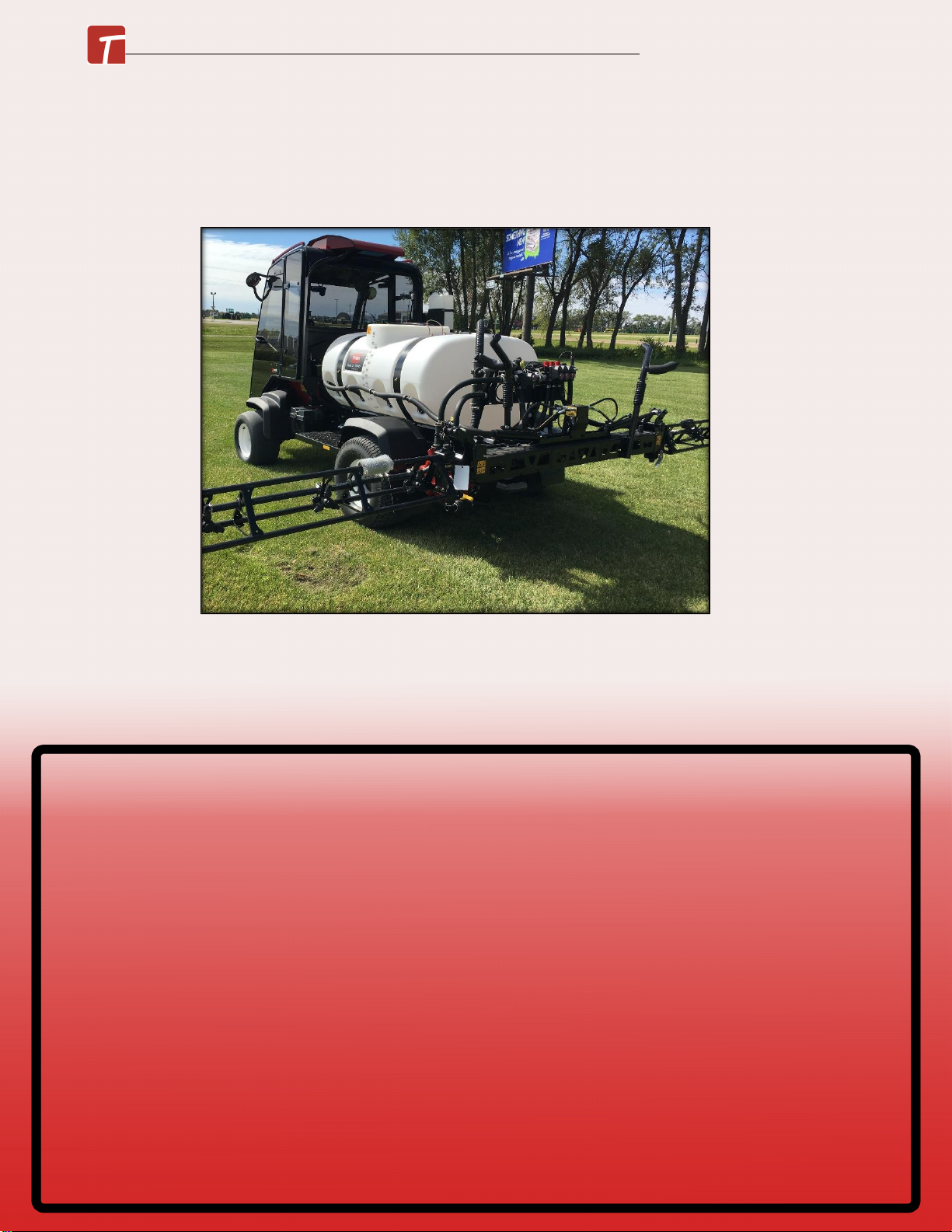

Tektite Toro Multi Pro MP5800-G ROPS Cab User manual

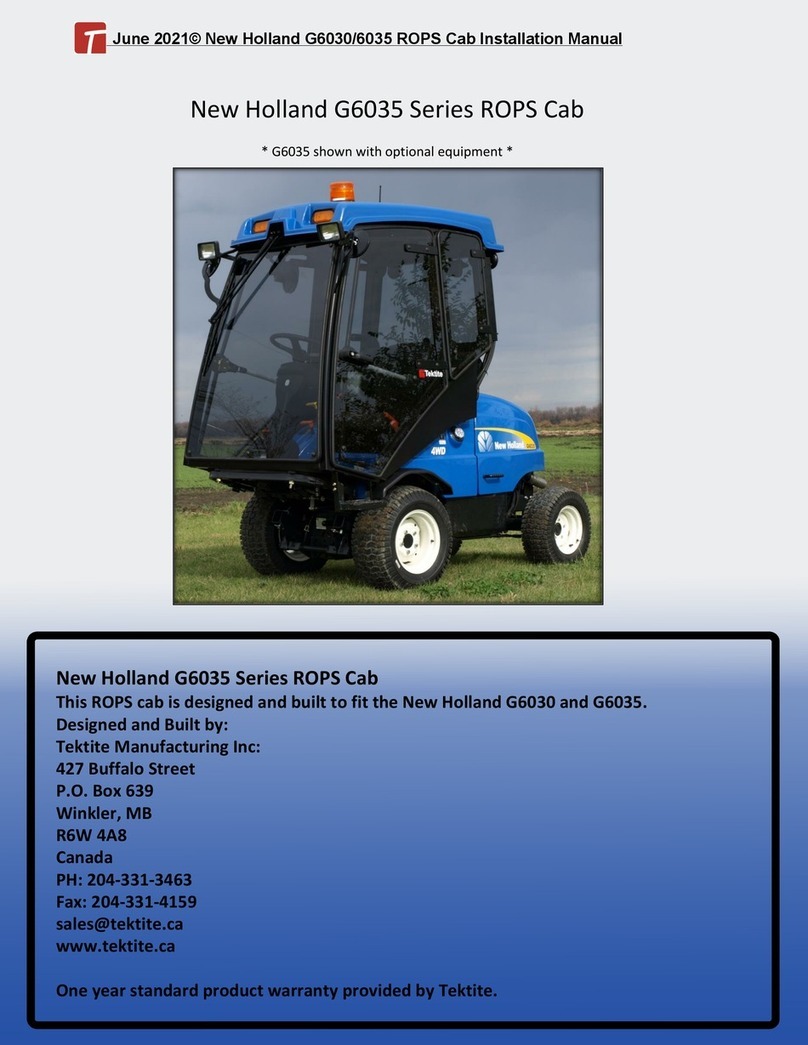

Toro MP5800-G ROPS Cab

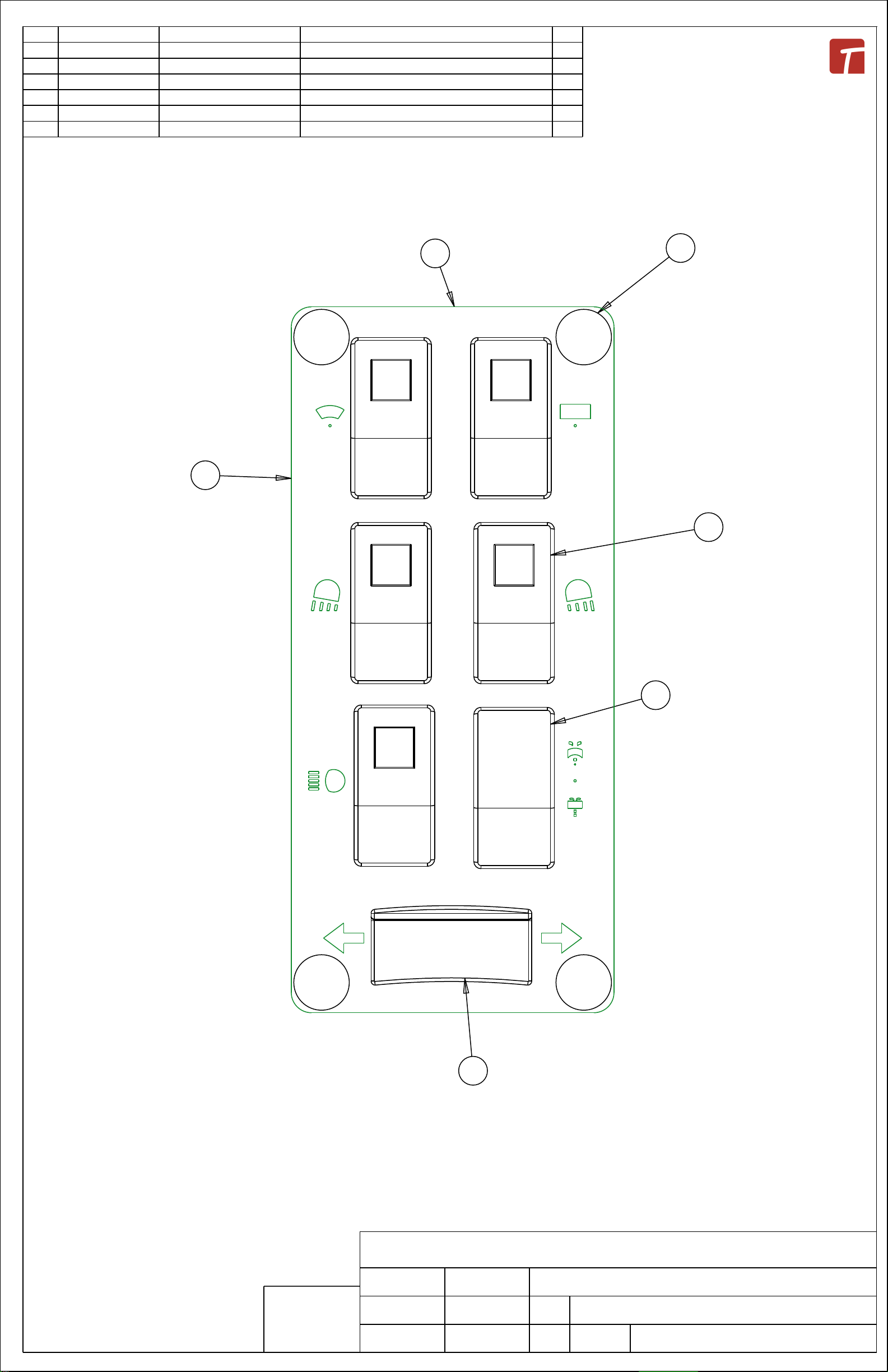

*Shown with optional Features *

June 2021© Toro MP5800-G ROPS Cab Operation Manual

*Operator must wear respirator when operating sprayer*

Toro MP5800-G ROPS Cab

This ROPS is designed and built to fit the Toro MP5800-G gas model.

Designed and Built by:

Tektite Manufacturing Inc:

427 Buffalo Street

P.O. Box 639

Winkler, MB

R6W 4A8

Canada

PH: 204-331-3463

Fax: 204-331-4159

www.tektite.ca

One year standard product warranty provided by Tektite.

Tektite Manufacturing Incorporated thanks you for purchasing a Toro MP5800-G ROPS Cab!

Tektite has worked very hard to design and build this ROPS product and we hope that it

provides you with many years of ROPS protection.

Tektite’s ROPS products are designed to provide safe and dependable service during operation

when they are properly maintained according to the instructions. Please read this operator

manual carefully before using this ROPS product.

The photos/illustrations provided in this manual may not provide all the detail needed, and are

for reference only.

All directions provided are from the reference point of the tractor seat facing the steering

wheel. All left and right references are from this view point.

For reference, please fill in the information below. This will assist your dealer in providing

service for this ROPS. It is advisable that this information be provided to your insurance

company as well in the event that the tractor is lost or damaged.

NOTE: Operator must wear full respirator when using spray vehicle.

Vehicle Model: _________________________________________________________

ROPS Serial Number: ___________________________________________________

Date of Purchase: _______________________________________________________

Dealer Name: ___________________________________________________________

June 2021© Toro MP5800-G ROPS Cab Operation Manual

Tektite Limited Warranty

Tektite Manufacturing Inc. (“Tektite”) warrants to the original purchaser (the “Claimant”), that Tektite products will

be free from defective materials or workmanship, under normal use and service, for a period of (1) full year from

the original invoice date. Tektite’s liability under this Limited Warranty is limited to the repair or (at the discretion

of Tektite) the replacement of those components of its products, which were manufactured by Tektite that are

defective in materials or workmanship. Tektite shall have no liability under this Limited Warranty unless Tektite is

notified of the defect during the stated Warranty Period.

Limitations and Exclusions: Tektite has no responsibility to a Claimant under this Limited Warranty or on any other

basis for any of the following:

a) defects caused, in whole or in part, by accident or misuse, negligence or failure to maintain the product or

component;

b) products or components sold to a customer on an “as is” basis;

c) wiper blades, light bulbs, fuses, clear vinyl or other consumables;

d) glass where the point of failure has not been preserved intact and delivered to Tektite for analysis of the

cause of the failure;

e) products or components which have been modified after shipping from Tektite to its customer;

f) transportation charges for returned, repaired or replacement items;

g) defects that are subject of a Tektite initiated recall where the Claimant fails to comply with the terms of

the recall notice that comes to the attention of the Claimant;

h) components of Tektite products that are manufactured by third parties (Tektite’s only obligation in relation

to such components shall be to accord to the Claimant the benefit of any transferable warranty accorded

to Tektite by third party manufacturer);

i) defects in workmanship or materials in products or components that are repaired or replaced by Tektite

unless Tektite is notified of the new defect within the Warranty Period that applied to the original product

or component that has been repaired or replaced;

j) defects that result, in whole or in part, from inadequate engineering or specifications provided to Tektite

by its customer;

k) any actual or alleged deficiency in technical or engineering services or advice provided by Tektite to its

customer whether provided for valuable consideration or otherwise;

l) consequential damages, or any other damages whether foreseeable or not, resulting from the defect or any

delay in remedying the defect;

m) any breach or alleged breach of any implied warranty of merchantability or fitness for particular purpose

of use;

n) defects or part failure due to misuse or failure to follow recommended cab installation procedures; and

o) travel expenses, including mileage.

This Limited Warranty expresses the entire obligation of Tektite, its officers, directors, agents and employees, to its

customer or any Claimant in respect of any defect in workmanship, or materials of any product or component sold

or manufactured by Tektite whether on grounds of breach of contract, negligence or other tortuous liability, breach

of express or implied warranty or other basis in law of any jurisdiction.

Acceptance by a customer of delivery of products of Tektite constitutes acceptance of this Limited Warranty in lieu

of all other warranties express or implied including without limitation all implied warranties of merchantability or

fitness for particular purpose or use and constitutes acceptance by customer of the exclusions and limitations of the

liability of Tektite set out above. Once received, the cab should have ALL exterior cardboard, Styrofoam wrapping

removed for immediate inspection of product to ensure that no damages have occurred during transportation.

Outer coverings should stay off the cab and the cab be stored indoors in a controlled environment.The warranty

card must be completed and returned to Tektite.

Warranty claims should be reported to parts@tektite.ca. A warranty claim form and instructions will be provided at this time.

Warranty work not pre-authorized by Tektite may not be covered by this warranty agreement. Labor rate and time allowances

are fixed by Tektite. Approved warranty claims will be issued in the form of credits applied to customer account.

June 2021© Toro MP5800-G ROPS Cab Operation Manual

Safety Precautions

Safety First

Read these instructions carefully. It is essential that you read the instructions and safety

regulations before you attempt to assemble or use the features that are on this cab/ROPS.

Danger: Indicates an immediate hazardous situation which, if not avoided, will result in death

or serious injury.

Warning: Indicates a potentially hazardous situation which, if not avoided, may result in death

or serious injury.

Caution: Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury.

Important: Indicates that cab or property damage may result if instructions are not carefully

followed.

NOTE: All products are designed to give safe, dependable service if they are operated and

maintained according to instructions. It is the owner’s responsibility to be certain anyone

operating this product reads this manual, and all other applicable manuals, to become familiar

with this cab and all safety precautions. Failure to do so could result in serious personal injury

or cab damage. If you have any questions, consult your dealer. Read and understand this

manual before operation.

NOTE: A safe operator is the best assurance against accidents. All operators, no matter how

experienced they may be, should read this operator manual and all other related manuals

before attempting to operate features in this cab/ROPS and operate the base tractor. Please

read the following section and pay particular attention to all safety recommendations

contained in this manual and those labelled on the cab and on the tractor.

June 2021© Toro MP5800-G ROPS Cab Operation Manual

General Safety

1. Never let an unqualified or untrained driver operate the spray vehicle.

2. Keep a fire extinguisher, with ABC rating securely fastened in the ROPS. Maintain it and be

familiar with its use.

3. Do not carry passengers.

4. Never operate the spray vehicle in a closed building for a prolonged period. Ensure adequate

ventilation is present, as engine exhaust fumes are poisonous and can kill.

5. Always keep sleeves, jackets or other loose clothing relatively tight and belted. Loose clothing

may catch on moving parts and result in severe personal injury or death.

6. Provide a first-aid kit, securely attached inside of the ROPS for use in case of accident.

7. Never jump from the spray vehicle. There is a danger of tripping or falling on protruding

parts.

8. Use steps and hand holds when mounting and dismounting the spray vehicle, or for servicing

components too high to reach from the ground.

9. When seated in the ROPS, fasten seat belt before starting the engine. A proper seat belt must

be worn at all times when using a ROPS.

10. Safety devices and shields are intended to protect operators from injury or death. Under no

circumstances should they be modified, disabled or removed.

11. Charcoal filter should be replaced once per season.

12. When operating spray vehicle, operator must wear respirator with cab.

Operating Safety

1. Always operate the spray vehicle controls while sitting in the operator’s seat.

2. Lock seat in position and buckle seat belt before operating the spray vehicle.

3. Avoid abrupt sharp turns at high speeds.

4. On sloped terrain, do not make sharp turns as machine stability could be compromised.

5. Operate the spray vehicle smoothly, avoid abrupt starts and stops.

6. Keep all shields in place when operating the spray vehicle.

7. Do not operate the spray vehicle when you are tired, sick, or impaired.

8. Never operate the spray vehicle in confined areas; visibility next to the tractor is reduced.

Injury to bystanders or damage to the ROPS or equipment may result.

Safety

Carefully review the procedures given in this manual and the spray vehicle operator’s manual

with all operators annually. It is important that all operators become familiar with, and follow

safety precautions. Operating instructions must be given to everyone using the tractor before

operation and at least once yearly thereafter in compliance with OSHA Regulations 1928.57

(United States).

June 2021© Toro MP5800-G ROPS Cab Operation Manual

Safe Operation on Rough Terrain

1. Drive the spray vehicle slowly on hillsides and curves to eliminate the danger of tipping.

Avoid slopes which are too steep for safe operation. Avoid sharp uphill turns.

2. Always drive slowly enough over rough ground or obstructions. Drive at speeds slows enough

to ensure your safety.

3. When driving out of a ditch, gully, or up a steep hillside, engage the clutch slowly. Avoid

sharp uphill turns.

4. When descending steep grades, select a sufficiently low gear to maintain control with

minimum use of braking.

5. Use caution when driving near the edge of a ditch or gully. It may cave in, causing the spray

vehicle to roll over.

6. Be alert when operating near trees, slopes and around obstructions. Tree branches can cause

damage to ROPS components.

Maintenance Safety

1. Remove mud, crop residue, chains, and tools from steps and operator’s platform. They may

interfere with pedal operation or entry/exit from spray vehicle.

2. When servicing components are too high to reach from the ground use steps and handholds.

Do not use fenders or shields that are not designed as steps.

Safe Highway Operation

1. Before operating the spray vehicle on, or near, public roadways check with your local

authorities for any local regulations that will affect you.

2. Equip towed implements with slow moving vehicle (SMV) signs when traveling on public

roads.

3. Install additional lights on implement rear to safeguard against rear end collisions.

4. Use hazard warning flashers as required by law when transporting or driving on public roads.

If the spray vehicle had warning flashers removed when mounting the ROPS, they must be

replaced prior to operation on public roads.

5. Keep to the right, yielding right-of-way traffic, especially if pulling implements. Pull off the

road and stop to allow motorists to pass. Drive on the road shoulder, if permitted by law.

6. Use extreme caution when pulling heavy loads at road speeds. Avoid hard application of the

spray vehicle brakes at high speed.

7. Always drive slowly near curbs, approaches or ditches.

8. If equipped, ensure headlights are aligned so they will not blind the operator’s of oncoming

vehicles. If the spray vehicle is not equipped with turn signals and law requires them, install

them prior to operating on or near public roads.

June 2021© Toro MP5800-G ROPS Cab Operation Manual

9. Use your turn signals, checking for traffic well in advance of turning. If the spray vehicle is not

equipped with turn signals and law requires them, install them prior to operating on or near

public roads.

Safety Decals

1. Keep decals clean. Remove dirt with a wet clean cloth when necessary.

2. Replace safety decals if destroyed, missing, painted over or unreadable. If any safety decals

are covered or obscured when the ROPS is mounted, it is recommended that you purchase

replacement decals from the spray vehicle manufacturer. Mount them in a readable location at,

or near, their original location before operating the spray vehicle.

3. New ROPS decals and spray vehicle decals are available from your spray vehicle dealer.

ROPS Safety

1. Install the ROPS in accordance with Tektite mounting instructions. Failure to do so may affect

the ROPS ability to withstand a roll over.

2. If the ROPS is subjected to alteration, structural damage or involved in an over turn accident,

the entire structure must be replaced. Failure to do so may result in injury or death in the event

of a roll over.

3. If the spray vehicle in not equipped with seat belts, purchase approved seat belts from the

spray vehicle manufacturer or Tektite prior to operating the spray vehicle.

4. Always fasten seat belts prior to operating the spray vehicle.

5. Always operate the spray vehicle from the operator’s seat.

6. Remove mud, crop residue, chains and tools from steps and operator’s platform. They may

interfere with pedal operation or entry/exit from the spray vehicle.

7. Remove all loose chains, tools, and equipment from the operator’s platform. Failure to do so

may cause injury or death in the event of a roll over.

8. Do not install the ROPS on a spray vehicle model that the ROPS is not designated for

(compatible spray vehicle designations are printed on the ROPS serial number plate). The ROPS

is designed specifically for individual models to ensure ROPS requirements will be met.

Installing the ROPS on a non designated spray vehicle may result in injury or death.

Emergency Exits

This ROPS has 2 exits, which may be used in an emergency: left and right side doors.

June 2021© Toro MP5800-G ROPS Cab Operation Manual

Operating Instructions

Important

The following section locates, identifies and briefly describes the functions of all cab controls.

All operators should familiarize themselves with control location and function prior to operating

the utility vehicle. Failure to do so may result in unsafe operation of the utility vehicle and

possible injury or death to operators and bystanders.

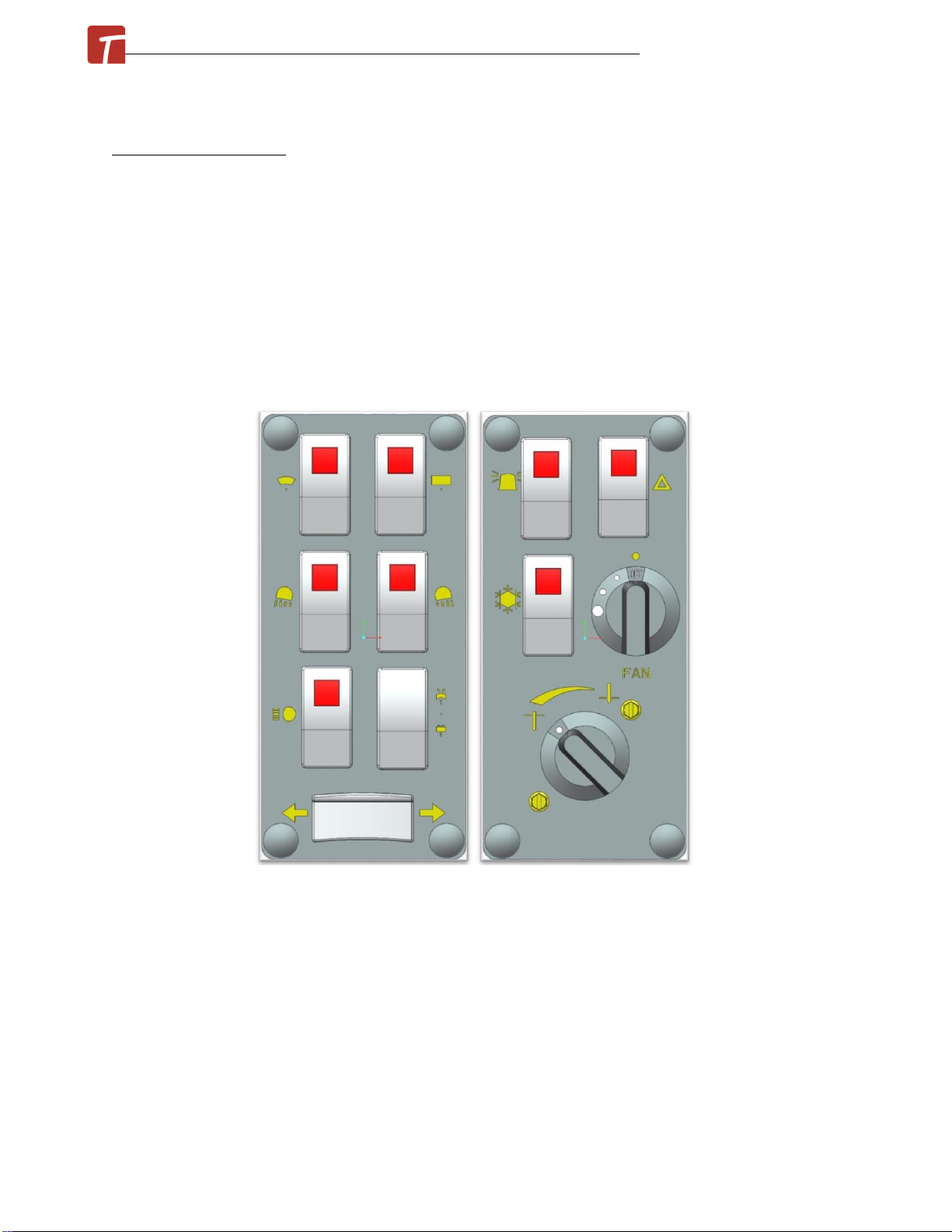

There are two switch plates located in the headliner. The following switches are available and

their functionality is described.

Left Switch Plate

1. Front Wiper Rocker Switch (standard)

Low position: Off

High position: On

Note: indicator light activates when wiper is on.

2. Rear Wiper Rocker Switch (optional)

Low position: Off

June 2021© Toro MP5800-G ROPS Cab Operation Manual

High position: On

Note: indicator light activates when wiper is on.

3. Front Work Light Rocker Switch (optional)

Low position: Off

High position: On

Note: indicator light activates when work lights are on.

4. Rear Work Light Rocker Switch (optional)

Low position: Off

High position: On

Note: indicator light activates when work light is on.

5. Head Lights Rocker Switch (optional)

Low position: Off

High position: On

Note: indicator light activates when head lights are on.

6. Front and Rear Washer Rocker Switch (optional)

Low position: Momentary –On Rear Washer

Middle position: Off

High position: Momentary –On Front Washer

7. Turn Signal Rocker Switch (optional)

Left position: On

Middle position: Off

Right position: On

Right Switch Plate

1. Beacon Rocker Switch (standard)

Low position: Off

High position: On

Note: indicator light activates when beacon is on.

2. Hazard Rocker Switch (optional)

Low position: Off

High position: On

Note: indicator light activates when 4-way flashers are on.

3. Air Conditioner Rocker Switch (optional)

Low position: Off

High position: On

Note: indicator light activates when air conditioner is on.

June 2021© Toro MP5800-G ROPS Cab Operation Manual

4. Fan Rotary Switch (optional)

Indicator mark above switch indicates whether fan is operational or not.

5. Temperature Control Rotary Switch (optional)

Indicator mark at lower left corner indicates current temperature setting. Rotate to increase

heat output or to decrease heat output of heating system. When air conditioner is being used,

it is recommended that the switch be at maximum cooling position.

Cab Circuit Protection

The Tektite ROPS cab is wired to provide maximum protection against accidental battery

rundown and circuit overload. A relay in the cab is ignition activated and prevents the operator

from accidentally leaving fan motors, lights on after turning the tractor off and leaving for the

day. A circuit breaker is provided to prevent the cab electrical components from drawing more

power than they should be able to from a dead short. The cab electrical components are also

fused individually, and the fuse block is located in the headliner, above the passenger seat on

the right side. Locate access door labelled Fuses, and open for access to examine the fuses. A

decal on the fuse block indicates which fuse is for which electrical option.

June 2021© Toro MP5800-G ROPS Cab Operation Manual

After your ROPS has been installed:

Before starting a spray vehicle equipped with a Tektite ROPS:

1. Clear the operator platform of all tools. Tools left in or around the ROPS and spray vehicle

can cause operator interference which could lead to bodily injury and/or damage the machine.

2. Inspect the ROPS and spray vehicle to ensure all bolts are tight and re-tighten if required.

3. Ensure that all pedals, levers, and controls have adequate clearance for normal operation.

4. Ensure that all electrical components of both the ROPS and spray vehicle operate normally.

5. Ensure your door latches properly onto the striker pin. Immediately after installation, the

ROPS frame may flex slightly from installation, and the door latch will need to be re-aligned for

proper operation. Loosen the striker pin, striker mounting plate and door latch as necessary to

get a proper alignment of the door striker.

Service Parts Breakdowns:

Following are parts breakdowns for components that may require service parts replacement

during the life of the ROPS. If you require replacement parts, please contact the dealer that

you purchased the ROPS from and indicate which parts you require.

June 2021© Toro MP5800-G ROPS Cab Operation Manual

Notice of Confidentiality

This material is property of Tektite Manufacturing

Inc and is not to be used by the recipient for any

purpose other than the purpose for which it was

transmitted. The material remains the property of

Tektite and shall be returned upon request. The

material may not be reproduced or disclosed to third

parties without the written consent of Tektite.

Tolerances:

Unless otherwise

specified

X.X = 1/16"

Angular = 1.0

Drawn By:

Checked By: Size:

File Name:

Units:

Date:

Date:

Req'd: Description:

Tektite Manufacturing Inc.

24157 Hwy 3, Box 639, Winkler MB, R6W 4A8, Canada

CNC:

Index Service Part # File Name

Description

Qty

1 A00-0013 TEKT-0009 5MM Bushing 14

2 A00-0014 THICK-BUSHING 8MM Bushing 6

3 A00-0019 STEP-BOLT1-4X1 Step Bolt, 1/4" x 1", MB 1

4 A00-0020 STEP-BOLT1-4X1-1-4 Step Bolt, 1/4" x 1 1/4", MB 6

5 A00-0021 FLANGE-NUT-1-4 Flange Nut, 1/4", YD 7

6 A00-0033 315-080 Rear Wiper Shaft Grommet 1

7 A00-0043 WWF-MOTOR WWF Wiper Motor, 1" Shaft 1

8 A00-0109 302-1160_BLADE Wiper Blade, 16", Narrow Saddle 1

9 A00-0316 TEKT-ASM-052 WWF, Adjustable Radial Arm, 14" Length 1

10 T06-0007 TO5700-045 Front Window 1

11 T06-0009 TO5700-078- Windshield Seal 1

Windshield Assembly

Daryl Furkalo

2017-07-18 Imp.

TO5700-ASM-015_OP

B

SCALE 0.200

1

2

3

4

5

6

7

10

11

8

9

Notice of Confidentiality

This material is property of Tektite Manufacturing

Inc and is not to be used by the recipient for any

purpose other than the purpose for which it was

transmitted. The material remains the property of

Tektite and shall be returned upon request. The

material may not be reproduced or disclosed to third

parties without the written consent of Tektite.

Tolerances:

Unless otherwise

specified

X.X = ± 1/16"

Angular = ± 1.0 °

Drawn By:

Checked By: Size:

File Name:

Units:

Date:

Date:

Req'd: Description:

Tektite Manufacturing Inc.

24157 Hwy 3, Box 639, Winkler MB, R6W 4A8, Canada

CNC:

Index Service Part # File Name

Description

Qty

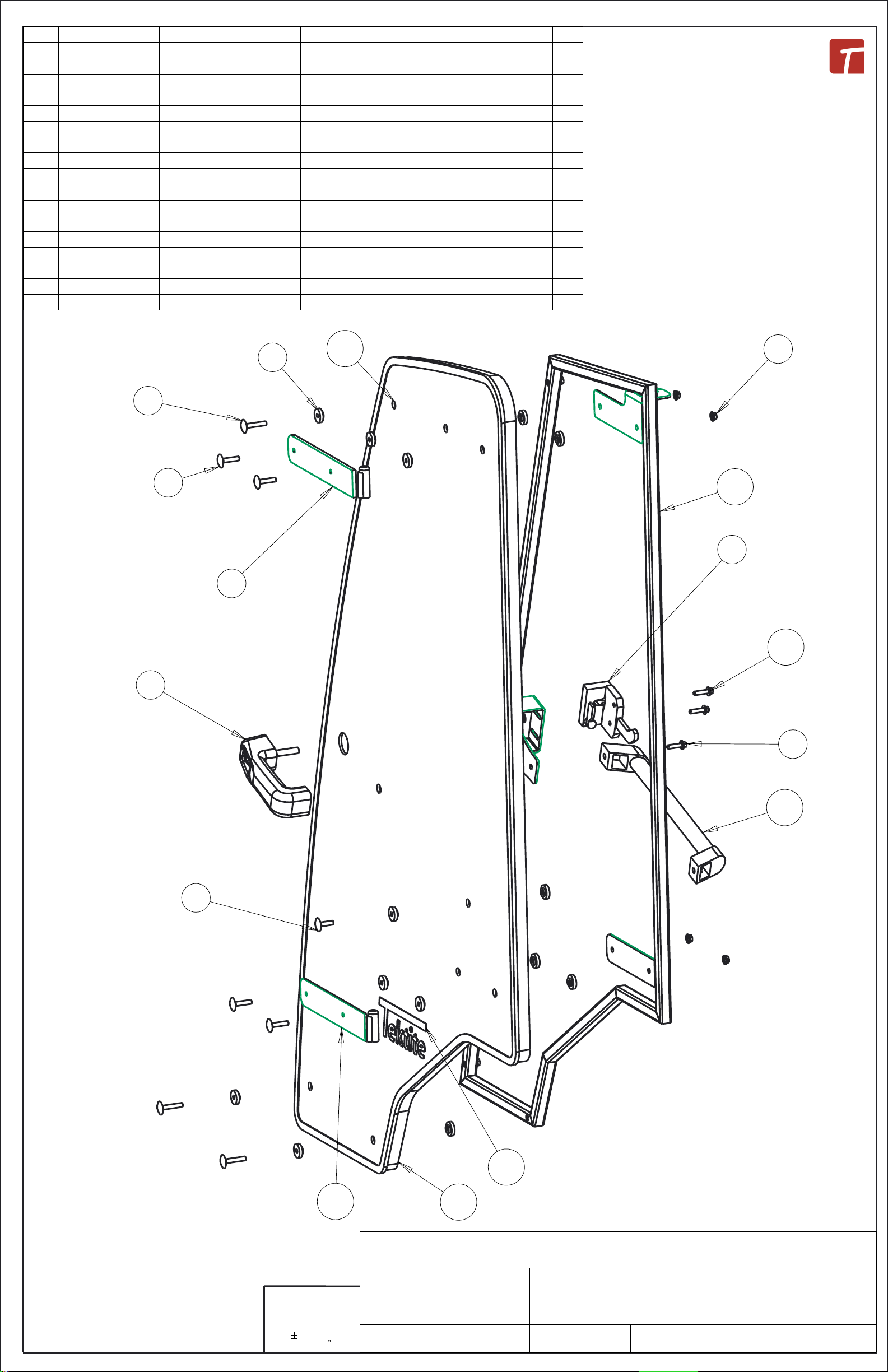

1 A00-0013 TEKT-0009 5MM Bushing 12

2 A00-0014 THICK-BUSHING 8MM Bushing 6

3 A00-0020 STEP-BOLT1-4X1-1-4 Step Bolt, 1/4" x 1 1/4", MB 6

4 A00-0021 FLANGE-NUT-1-4 Flange Nut, 1/4", YD 6

5 T06-0005 TO5700-077 Rear Window Weather Seal 1

6 T06-0006 TO5700-044 Rear Window 1

Rear Window Assembly

Daryl Furkalo

2010-09-01 Imp.

TO5700-ASM-014_OP

B

SCALE 0.220

12

3

4

5

6

Notice of Confidentiality

This material is property of Tektite Manufacturing

Inc and is not to be used by the recipient for any

purpose other than the purpose for which it was

transmitted. The material remains the property of

Tektite and shall be returned upon request. The

material may not be reproduced or disclosed to third

parties without the written consent of Tektite.

Tolerances:

Unless otherwise

specified

X.X = ± 1/16"

Angular = ± 1.0 °

Drawn By:

Checked By: Size:

File Name:

Units:

Date:

Date:

Req'd: Description:

Tektite Manufacturing Inc.

24157 Hwy 3, Box 639, Winkler MB, R6W 4A8, Canada

CNC:

Index Service Part # File Name

Description

Qty

1 A00-0013 TEKT-0009 5MM Bushing 8

2 A00-0019 STEP-BOLT1-4X1 Step Bolt, 1/4" x 1", MB 4

3 A00-0021 FLANGE-NUT-1-4 Flange Nut, 1/4", YD 4

4 A00-0044 TEKT-ASM-002 Side Window Hinge Weldment 2

5 A00-0057 TEKT-0020MIR Side Window Latch, L60776 1

6 A00-0058 CARRIAGE_BOLT-5-16X1 Bolt, Carriage, 5/16"x 1", YD 1

7 A00-0059 FLANGE-NUT-5-16 Flange Nut, 5/16", YD 1

8 A00-0087 TEKT-0028 Side Window Slider Bracket 1

9 A00-0119 WASHER_1-4 Washer, Flat, 1/4" 2

10 T06-0003 TO5700-046 Side Window Glass 1

11 T06-0008 TO5700-076R Side Window Weather Seal 1

Right Side Window Assembly

Daryl Furkalo

2010-09-01 Imp.

TO5700-ASM-013_OP

B

SCALE 0.250

11

10

9

8

7

6

5

4

3

2

1

Notice of Confidentiality

This material is property of Tektite Manufacturing

Inc and is not to be used by the recipient for any

purpose other than the purpose for which it was

transmitted. The material remains the property of

Tektite and shall be returned upon request. The

material may not be reproduced or disclosed to third

parties without the written consent of Tektite.

Tolerances:

Unless otherwise

specified

X.X = ± 1/16"

Angular = ± 1.0 °

Drawn By:

Checked By: Size:

File Name:

Units:

Date:

Date:

Req'd: Description:

Tektite Manufacturing Inc.

24157 Hwy 3, Box 639, Winkler MB, R6W 4A8, Canada

CNC:

Index Service Part # File Name

Description

Qty

1 A00-0013 TEKT-0009 5MM Bushing 8

2 A00-0019 STEP-BOLT1-4X1 Step Bolt, 1/4" x 1", MB 4

3 A00-0021 FLANGE-NUT-1-4 Flange Nut, 1/4", YD 4

4 A00-0046 TEKT-ASM-002R Side Window Hinge Right 2

5 A00-0056 TEKT-0020 Side Window Latch, L60775 1

6 A00-0058 CARRIAGE_BOLT-5-16X1 Bolt, Carriage, 5/16"x 1", YD 1

7 A00-0059 FLANGE-NUT-5-16 Flange Nut, 5/16", YD 1

8 A00-0087 TEKT-0028 Side Window Slider Bracket 1

9 A00-0119 WASHER_1-4 Washer, Flat, 1/4" 2

10 T06-0003 TO5700-046 Side Window Glass 1

11 T06-0008 TO5700-076 Side Window Weather Seal 1

Left Side Window Assembly

Daryl Furkalo

2010-09-01 Imp.

TO5700-ASM-012_OP

B

SCALE 0.250

1

2

3

11

10 9

8

7

6

5

4

Notice of Confidentiality

This material is property of Tektite Manufacturing

Inc and is not to be used by the recipient for any

purpose other than the purpose for which it was

transmitted. The material remains the property of

Tektite and shall be returned upon request. The

material may not be reproduced or disclosed to third

parties without the written consent of Tektite.

Tolerances:

Unless otherwise

specified

X.X = 1/16"

Angular = 1.0

Drawn By:

Checked By: Size:

File Name:

Units:

Date:

Date:

Req'd: Description:

Tektite Manufacturing Inc.

24157 Hwy 3, Box 639, Winkler MB, R6W 4A8, Canada

CNC:

Index Service Part # File Name

Description

Qty

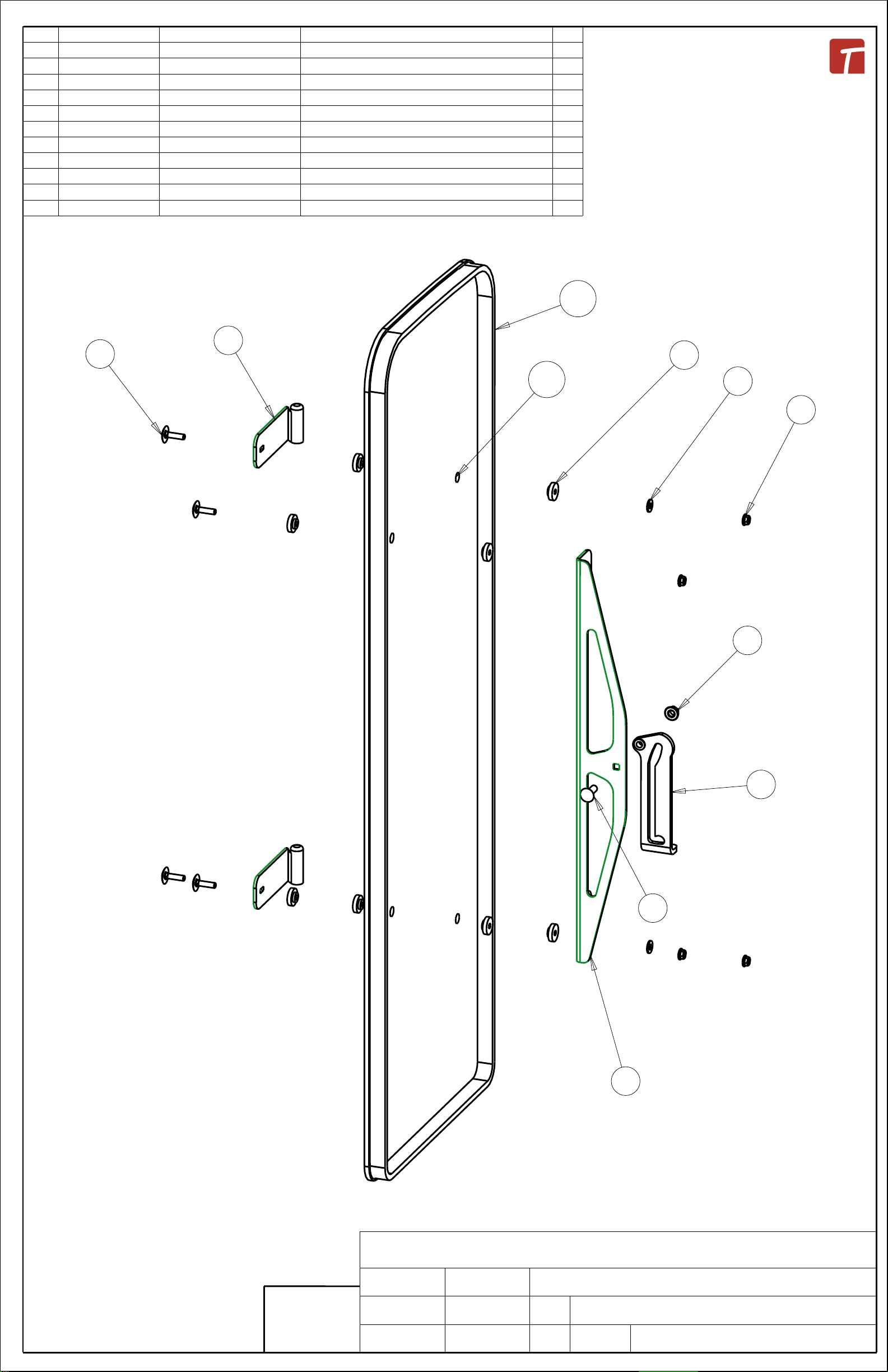

1 A00-0001 DLP-HANDLE Outside Push Button Handle 1

2 A00-0003 RIGHT-LATCH Suicide Door Right Latch 1

3 A00-0013 TEKT-0009 5MM Bushing 17

4 A00-0018 STEP-BOLT1-4X1-1-2 Step Bolt, 1/4" x 1 1/2", MB 3

5 A00-0019 STEP-BOLT1-4X1 Step Bolt, 1/4" x 1", MB 1

6 A00-0020 STEP-BOLT1-4X1-1-4 Step Bolt, 1/4" x 1 1/4", MB 4

7 A00-0021 FLANGE-NUT-1-4 Flange Nut, 1/4", YD 10

8 A00-0022 FLANGE_BOLT_M6X25 Flange Bolt, M6x25, YD 1

9 A00-0040 REID-RST-160-RST-163 Grab Handle 1

10 A00-0041 TEKTITE-DECAL Tektite Cab Decal - Solid White 1

11 A00-0042 TEKT-ASM-001R Right Cab Door Hinge Weldment, Upper 1

12 A00-0118 FLANGE_BOLT_1-4X1 Flange Bolt, 1/4" x 1", YD 2

13 A00-0177 TEKT-0068 Handle Washer Spacer 1

14 A00-0229 TEKT-ASM-029R Right Door Hinge Weldment, Lower 1

15 T06-0002 TO5700-ASM-008_RT Right Door Frame Weldment 1

16 T06-0004 TO5700-048 Door Glass 1

17 T06-0011 TO5700-075R Door WeatherSeal 1

Right Door Assembly

Daryl Furkalo

2014-04-02 Imp.

TO5700-ASM-007_RT_OP

B

SCALE 0.170

17

16

15

12

11

9

8

7

6

4

5

3

1

2

13

Notice of Confidentiality

This material is property of Tektite Manufacturing

Inc and is not to be used by the recipient for any

purpose other than the purpose for which it was

transmitted. The material remains the property of

Tektite and shall be returned upon request. The

material may not be reproduced or disclosed to third

parties without the written consent of Tektite.

Tolerances:

Unless otherwise

specified

X.X = 1/16"

Angular = 1.0

Drawn By:

Checked By: Size:

File Name:

Units:

Date:

Date:

Req'd: Description:

Tektite Manufacturing Inc.

24157 Hwy 3, Box 639, Winkler MB, R6W 4A8, Canada

CNC:

Index Service Part # File Name

Description

Qty

1 A00-0001 DLP-HANDLE Outside Push Button Handle 1

2 A00-0002 LEFT-LATCH Suicide Door Left Latch 1

3 A00-0013 TEKT-0009 5MM Bushing 17

4 A00-0018 STEP-BOLT1-4X1-1-2 Step Bolt, 1/4" x 1 1/2", MB 3

5 A00-0019 STEP-BOLT1-4X1 Step Bolt, 1/4" x 1", MB 1

6 A00-0020 STEP-BOLT1-4X1-1-4 Step Bolt, 1/4" x 1 1/4", MB 4

7 A00-0021 FLANGE-NUT-1-4 Flange Nut, 1/4", YD 10

8 A00-0022 FLANGE_BOLT_M6X25 Flange Bolt, M6x25, YD 1

9 A00-0039 TEKT-ASM-001 Left Door Hinge Weldment, Upper 1

10 A00-0040 REID-RST-160-RST-163 Grab Handle 1

11 A00-0041 TEKTITE-DECAL Tektite Cab Decal - Solid White 1

12 A00-0118 FLANGE_BOLT_1-4X1 Flange Bolt, 1/4" x 1", YD 2

13 A00-0177 TEKT-0068 Handle Washer Spacer 1

14 A00-0228 TEKT-ASM-029 Left Door Hinge Weldment, Lower 1

15 T06-0001 TO5700-ASM-008 Left Door Frame Weldment 1

16 T06-0004 TO5700-048 Door Glass 1

17 T06-0011 TO5700-075 Door WeatherSeal 1

Left Door Assembly

Daryl Furkalo

2014-04-02 Imp.

TO5700-ASM-007_OP

B

SCALE 0.200

1

2

3

17

16

15

12

11

10

9

8

7

6

4

5

14

Notice of Confidentiality

This material is property of Tektite Manufacturing

Inc and is not to be used by the recipient for any

purpose other than the purpose for which it was

transmitted. The material remains the property of

Tektite and shall be returned upon request. The

material may not be reproduced or disclosed to third

parties without the written consent of Tektite.

Tolerances:

Unless otherwise

specified

X.X = 1/16"

Angular = 1.0

Drawn By:

Checked By: Size:

File Name:

Units:

Date:

Date:

Req'd: Description:

Tektite Manufacturing Inc.

24157 Hwy 3, Box 639, Winkler MB, R6W 4A8, Canada

CNC:

Index Service Part # File Name

Description

Qty

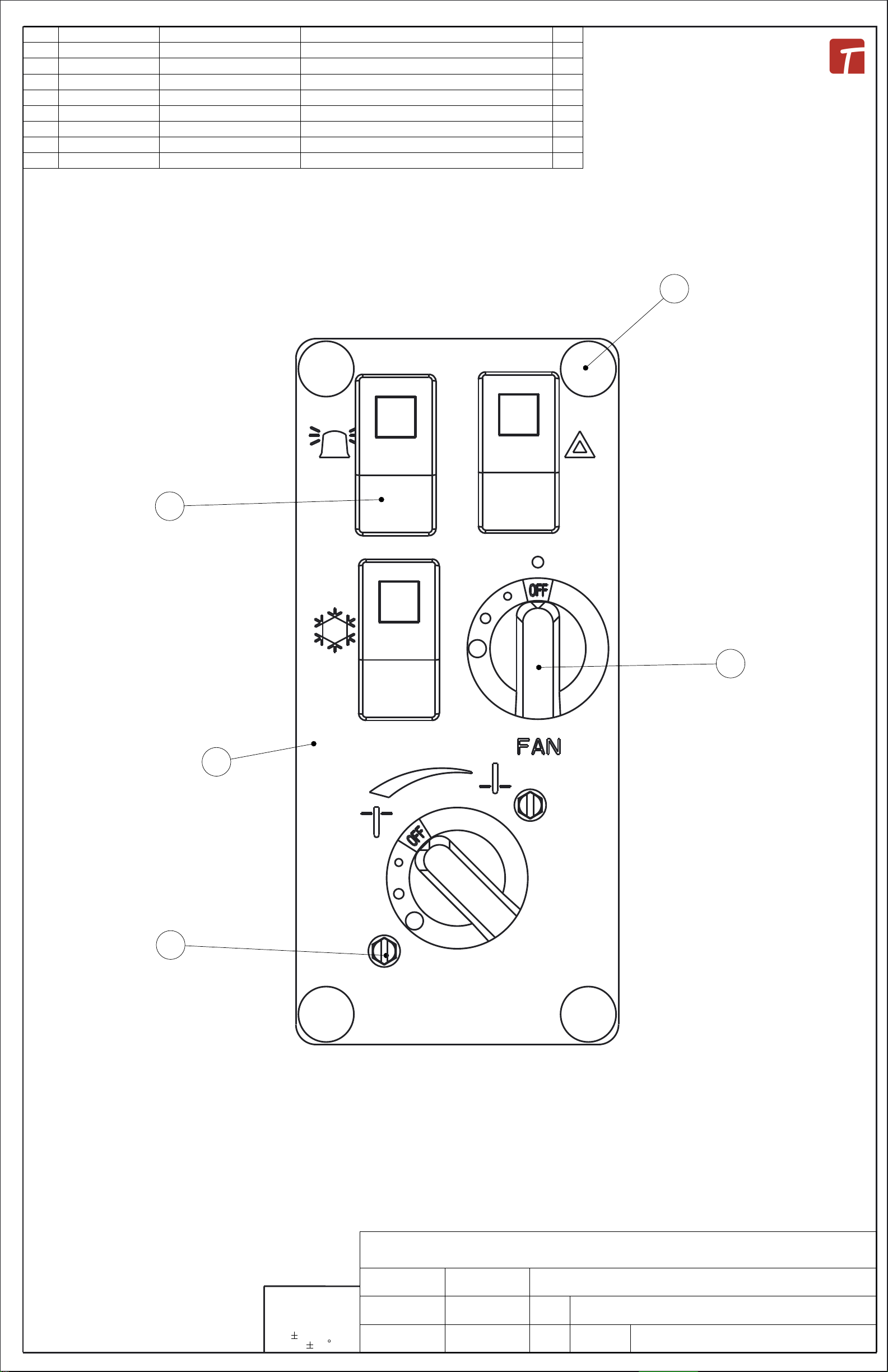

1 A00-0007 FAN-SWITCH 4-Position Fan Switch 1

2 A00-0054 TEKT-0018 Fan Speed Control Knob 2

3 A00-0055 TEKT-0019 Fir Tree Fastener 4

4 A00-0065 TEKT-ASM-005 On-Off Switch w/Lens 3

5 A00-0252 TEKT-0117 Water Valve Directly on Switch 1

6 A00-0253 TEKT-0119 Right Switchplate Decal, 2014 Update 1

7 A00-0282 SCREW-3-16X3-4 Screw, Self-Tap, 3/16" x 3/4" 2

8 A00-0283 TEKT-0118 Right Switchplate, 2014 Redesign 1

New Valve Design Switch Plate, 2014

Daryl Furkalo

2014-02-05 Imp.

TEKT-ASM-030

B

SCALE 1.000

2

3

4

7

6

Notice of Confidentiality

This material is property of Tektite Manufacturing

Inc and is not to be used by the recipient for any

purpose other than the purpose for which it was

transmitted. The material remains the property of

Tektite and shall be returned upon request. The

material may not be reproduced or disclosed to third

parties without the written consent of Tektite.

Tolerances:

Unless otherwise

specified

X.X = ± 1/16"

Angular = ± 1.0 °

Drawn By:

Checked By: Size:

File Name:

Units:

Date:

Date:

Req'd: Description:

Tektite Manufacturing Inc.

24157 Hwy 3, Box 639, Winkler MB, R6W 4A8, Canada

CNC:

Index Service Part # File Name Description Qty

1 A00-0055 TEKT-0019 Fir Tree Fastener 4

2 A00-0063 LEFT-CAB-SWITCHPLATE Left Switchplate 1

3 A00-0064 LEFT-CAB-SWITCHPLATE-DECAL Left Switchplate Decal 1

4 A00-0065 TEKT-ASM-005 On-Off Switch w/Lens 5

5 A00-0066 TEKT-ASM-006 On-Off-On Rocker No Lens 1

6 A00-0067 TEKT-ASM-007 Mom-Off-Mom Rocker Switch 1

Operator Manual Switch Plate Left

Daryl Furkalo

2009-03-09 Imp. LEFT-SWITCHPLATE-ASM

B

1.000SCALE

1

2

3

4

5

6

Notice of Confidentiality

This material is property of Tektite Manufacturing

Inc and is not to be used by the recipient for any

purpose other than the purpose for which it was

transmitted. The material remains the property of

Tektite and shall be returned upon request. The

material may not be reproduced or disclosed to third

parties without the written consent of Tektite.

Tolerances:

Unless otherwise

specified

X.X = 1/16"

Angular = 1.0

Drawn By:

Checked By: Size:

File Name:

Units:

Date:

Date:

Req'd: Description:

Tektite Manufacturing Inc.

24157 Hwy 3, Box 639, Winkler MB, R6W 4A8, Canada

CNC:

Index Service Part # File Name

Description

Qty

1 TO5700-ASM-021 Cab Weldment Assembly 1

2 A00-0016 TEKT-0075 Domelight LED 1

3 A00-0021 FLANGE-NUT-1-4 Flange Nut, 1/4", YD 4

4 A00-0023 FLANGE_BOLT_1-4X3-4 Flange Bolt, 1/4" x 3/4", YD 4

5 A00-0025 BALL-LOUVER 2 1/2" Ball Louver 4

6 A00-0028 TEKT-0088 Red Dot Drier 1

7 A00-0055 TEKT-0019 Fir Tree Fastener 2

8 A00-0059 FLANGE-NUT-5-16 Flange Nut, 5/16", YD 2

9 A00-0070 REID-KBP-262-KBP-265 Knob, Knurled, 1/4" 2

10 A00-0071 LEFT-SWITCHPLATE-ASM Left Switchplate Assembly 1

11 A00-0072 TEKT-ASM-030 Right Switchplate Assembly, 2014 Update 1

12 A00-0074 TEKT-ASM-004 Fuse Block Assembly 1

13 A00-0078 TEKT-ASM-025 Condenser Assembly 1

14 A00-0084 TEKT-0070 Gas Shock 2

15 A00-0085 TEKT-0069 Gas Shock Stud 2

16 A00-0105 R-2300-2_090902 Heater A/C Blower Unit, 2300 1

17 A00-0141 ROUND_MIRROR_6_INCH External 6" Mirror 2

18 A00-0171 TEKT-0089 Binary Switch 1

19 A00-0179 FLANGE-NUT-1-2 1/2" Nut 2

20 A00-0192 COUPLER-NUT_1-4X2 Coupler Nut, 1/4" x 2" 4

21 A00-0202 TEKT-ASM-009R Right Mirror Bracket Weldment 1

22 A00-0203 TEKT-ASM-009 Left Mirror Bracket Weldment 1

23 A00-0204 TEKT-ASM-011 Louver Hose Mount Plate, 2300 1

24 A00-0222 TO5700-ASM-022 Fuse Block Cover Assembly 1

25 A00-0371 TEKT-0175 New LED Work Light (Blazer Intl) 2

26 A00-0389 KUBX2380-NOSTRIL Plastic Light Nostril 2

27 T06-0012 TO5700-066 Outer Filter Cover 1

28 T06-0015 TO5700-059 Air Filter 1

29 T06-0021 TO5700-ASM-023 Roof Cap Assembly, Oct 2013 1

Cab Assembly Parts Oct 2013

Daryl Furkalo

2017-07-06 Imp.

TO5700-ASM-024_OP

B

SCALE 0.100

2

3

4

5

6

7

8

9

11 10

12

13

14

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Table of contents

Other Tektite Farm Equipment manuals

Popular Farm Equipment manuals by other brands

FENDT

FENDT BALER Series Operator's manual

Grammer

Grammer MAXIMO Evolution Dynamic operating instructions

SUREHATCH

SUREHATCH SETTER SH2160 user manual

Fratelli Camisa

Fratelli Camisa TP 280 ECO Instruction manual for use and maintenance

Yetter

Yetter 5000 SERIES owner's manual

Kerbl

Kerbl 37102 Instructions for use