INSTALLATION

INSTRUCTIONS

BUILT-IN FULL HEIGHT WINE CELLAR

(VCWB300 PROFESSIONAL MODEL)

Retain for Future Reference

VIKING RANGE CORPORATION

111 Front Street

Greenwood, Mississippi 38930 USA

(662) 455-1200

IMPORTANT - PLEASE READ AND FOLLOW

Make sure that incoming voltage is the same as unit rating. An electric rating plate specifying voltage, frequency, wattage,

amperage, and phase is attached to the product.

To reduce the risk of fire, electric shock, or injury to persons, installation work and electrical wiring must be done by qualified

people in accordance with all applicable codes and standards, including fire-rated construction.

The installer should leave these instructions with the consumer who should retain them for local inspector’s use and for

future reference.

GENERAL INFORMATION

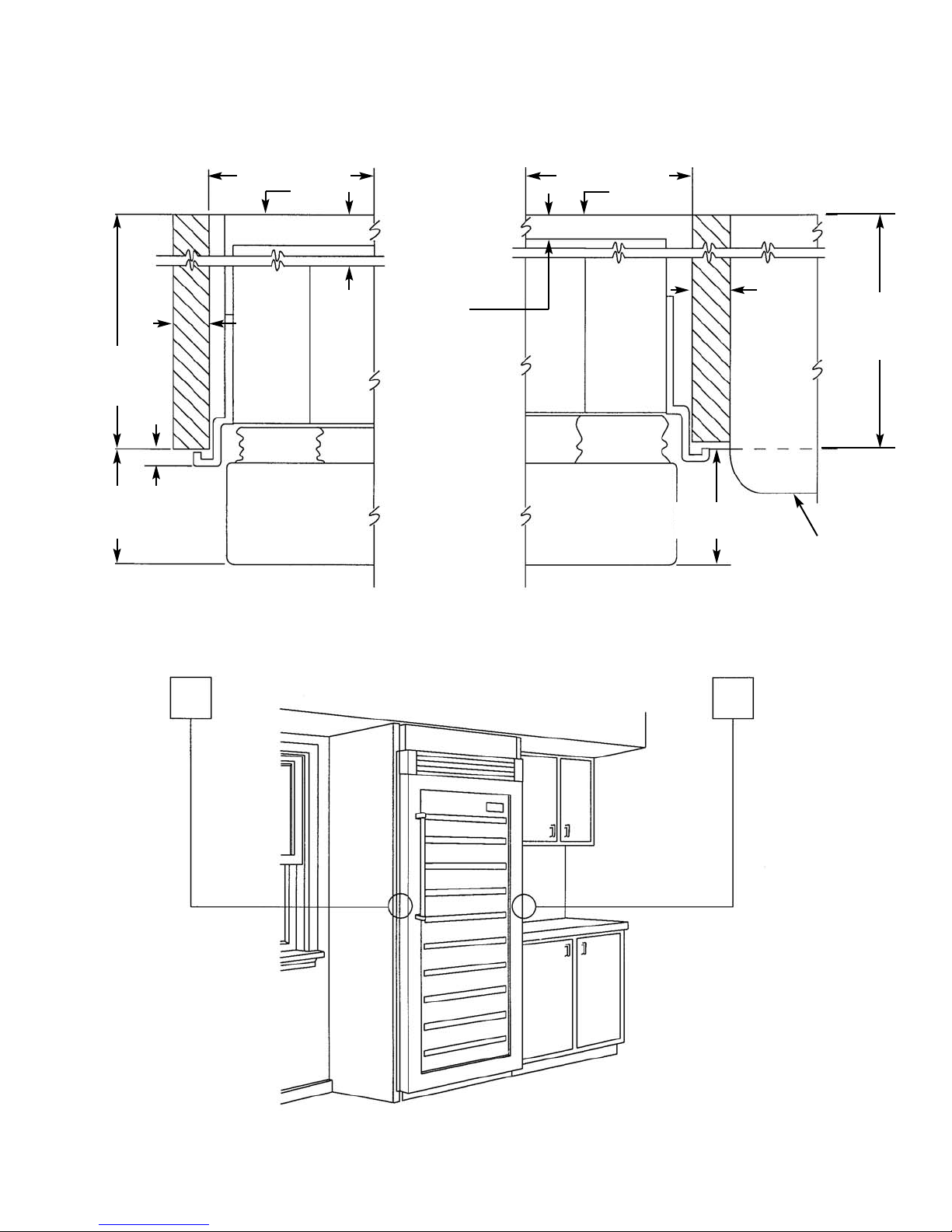

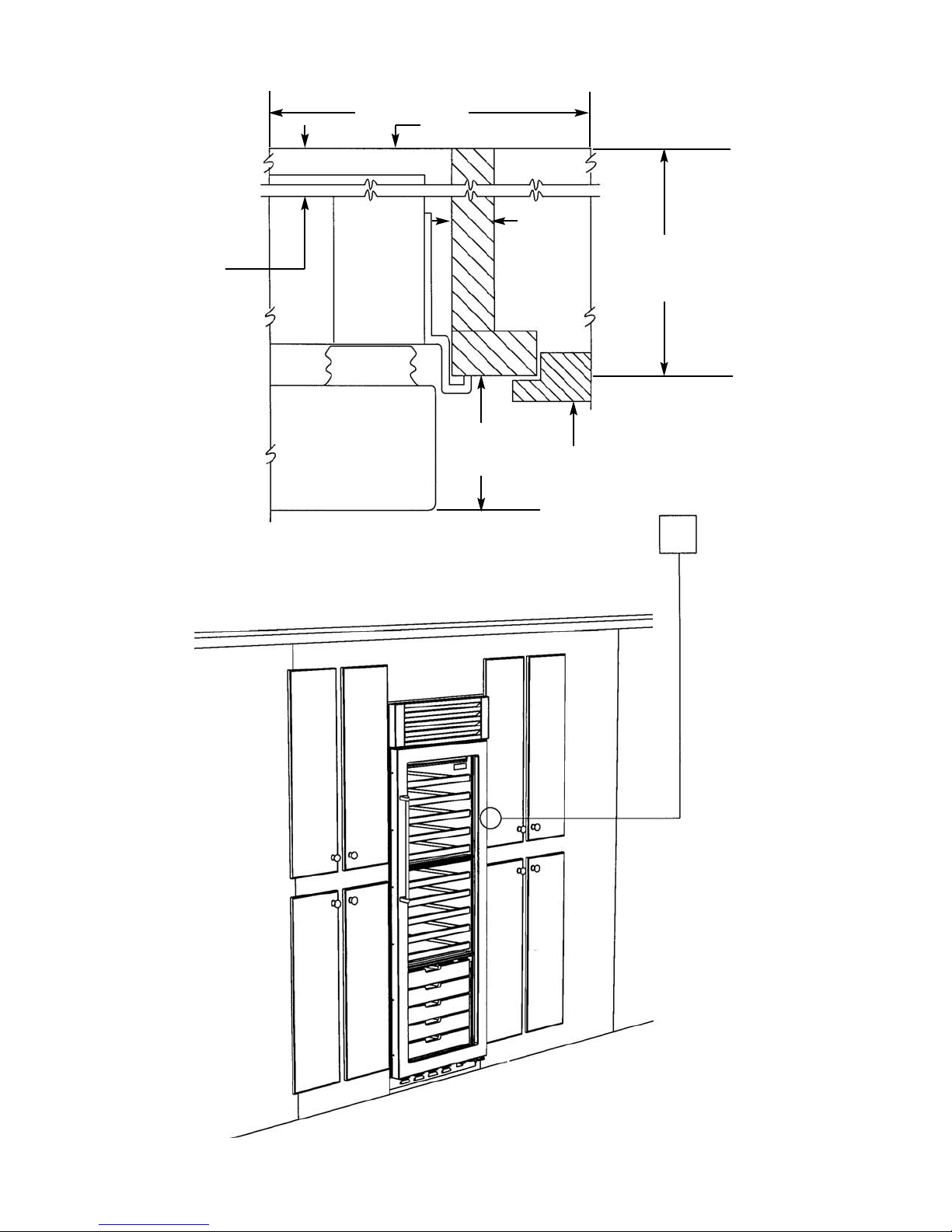

It is your responsibility to :

-comply with installation specifications and dimensions

-properly install wine cellar

-remove any moldings or decorative panels that prevent the wine cellar

from being serviced

-assure that floor will support wine cellar, door panels and contents

(approximately 1200 lbs. [540 kg]).

-provide a properly grounded electrical outlet

-assure that location will permit appliance doors to open 90ominimum

TTIIPPOOVVEERRHHAAZZAARRDD

WWiinneecceellllaarriissttoopphheeaavvyyaannddttiippsseeaassiillyy

wwhheennnnoottccoommpplleetteellyyiinnssttaalllleedd..

KKeeeeppddoooorrccl

loosseeddaannddsshheellvveessiinnppllaaccee

uunnttiillwwiinneecceellllaarriissccoommpplleetteellyyiinnssttaalllleedd

ppeerriinnssttaallllaattiioonniinnssttrruuccttiioonnss..

UUsseettwwoooorrmmoorreeppeeoopplleettoommoovveeaanndd

iinnssttaallllwwiinneecceellllaarr..

FFaaiilluurreettooddoossooccaannrreessuullttiinnddeeaatthhoorr

sseerriioou

ussiinnjjuurryy..

MMoossttoofftthheewwiinneecceellllaarr’’sswweeiigghhttiissaatttthhee

ttoopp..EExxttrraaccaarreeiissnneeeeddeeddwwhheennmmoovviinngg

tthheewwiinneecceellllaarrttoo

pprreevveennttttiippppiinngg..

UUsseeccaarrddbbooaarrddsshhiippppiinnggmmaatteerriiaalloorr

ppllyywwoooodduunnddeerrwwiinneecceellllaarruunnttiilliittiiss

iinnssttaalllleedd

iinntthheeooppeerraattiinnggppoossiittiioonnttoo

pprrootteeccttfflloooorrssuurrffaaccee..

YYoouurrssaaffeettyyaannddtthheessaaffeettyyooffootthheerrss

iissvveerryyiimmppoorrttaanntt..

We have provided many important safety

messages in this manual and on your

appliance. Always read and obey all

safety messages.

This is the safety alert symbol. This

symbol alerts you to hazards that

can kill or hurt you and others.

All safety messages will be

preceded by the safety alert symbol and

the word “DANGER” or “WARNING”.

These words mean:

YYoouuwwiillllbbeekkiilllleeddoorrsseerriioouussllyyiinnjjuurre

eddiiffyyoouu

ddoonn’’ttffoolllloowwiinnssttrruuccttiioonnss..

YYoouuccaannbbeekkiilllleeddoorrsseerriioouussllyyiinnjjuurreeddiiff

yyoouuddoonn’’ttffoolllloowwiinnssttr

ruuccttiioonnss..

All safety messages will identify the

hazard, tell you how to reduce the chance

of injury, and tell you what can happen if

the instructions are not followed.