3

BBAASSIICCSSPPEECCIIFFIICCAATTIIOONNSSAANNDDDDIIMMEENNSSIIOONNSS

FFrreeeessttaannddiinnggBBoottttoommMMoouunntt//FFrreenncchhDDoooorrBBoottttoommMMoouunntt

DDEESSCCRRIIPPTTIIOONNVVCC//DDDDBBFF//VVCC//DDDDFFFF

Overall Width 35 5/8” (90.5 cm)

Addition of side panels: 35 7/8” (91.1 cm)

Overall Height from Bottom 70 1/8” (178.1 cm)

Addition of tops/grilles: 71 7/8” (182.6 cm)

Overall Depth from Rear To front of door: 26 3/4” (67.9 cm)

Cutout Width 36” (91.4 cm)

Cutout Height 70 1/2” (179.0 cm)

Addition of tops/grilles 72” (182.9 cm)

Cutout Depth 24” (61.0 cm)

Electrical Requirements 115 volt, 60 Hz, 15 amp dedicated circuit; 3-wire cord with grounded 3-prong

plug attached to product.

Maximum Amp Usage 7.9 amps

Inlet Water Requirements 1/4” copper tubing inlet waterline; minimum 35 psi; maximum 100 psi

Overall Interior Capacities Bottom Mount French Door Bottom Mount

•Refrigerator 14.4 cu. ft. (407 liters) 14.1 cu. ft. (399 liters)

•Freezer 5.5 cu. ft. (156 liters) 5.5 cu. ft. (156 liters)

•Total Capacity 19.9 cu. ft. (563 liters) 19.6 cu. ft. (555 liters)

Approximate Shipping Weight 327 lbs. (148.7 kg)

DANGER

RRiisskkooffCChhiillddEEnnttrraappmmeenntt

BBEEFFOORREEYYOOUUTTHHRROOWWAAWWAAYYYYOOUURROOLLDD

RREEFFRRIIGGEERRAATTOORROORRFFRREEEEZZEERR::

•Take off the doors.

•Leave the shelves in place so that children

may not easily climb inside.

IIMMPPOORRTTAANNTT::Child entrapment and

suffocation are not problems of the past.

Junked or abandoned refrigerators are still

dangerous... even if they will sit for “just a few

days.”

IIttiisstthheeccuussttoommeerr’’ssrreessppoonnssiibbiilliittyyttoo::

•contact a qualified electrical installer.

•assure that the electrical installation is adequate and in conformance with the National Electrical Code, ANSI/NFPA

70-latest edition or Canadian Electrical Code C22.1-1998 and C22.2 No. 0-M91 (or latest edition), and all local codes

and ordinances. (115 volt, 60-Hz, 15 amp, fused, electrical supply is required. It is required that a separate circuit

serving only this appliance be provided. This appliance is equipped with a power supply cord having a 3-prong

grounding plug. To minimize possible shock hazard, the cord must be plugged into a mating 3-prong, grounding-

type wall receptacle. If a 2-prong receptacle is encountered, the customer must contact a qualified electrical installer

to have it replaced with a properly grounded 3-prong receptacle. Do not use an extension cord or adapter plug.)

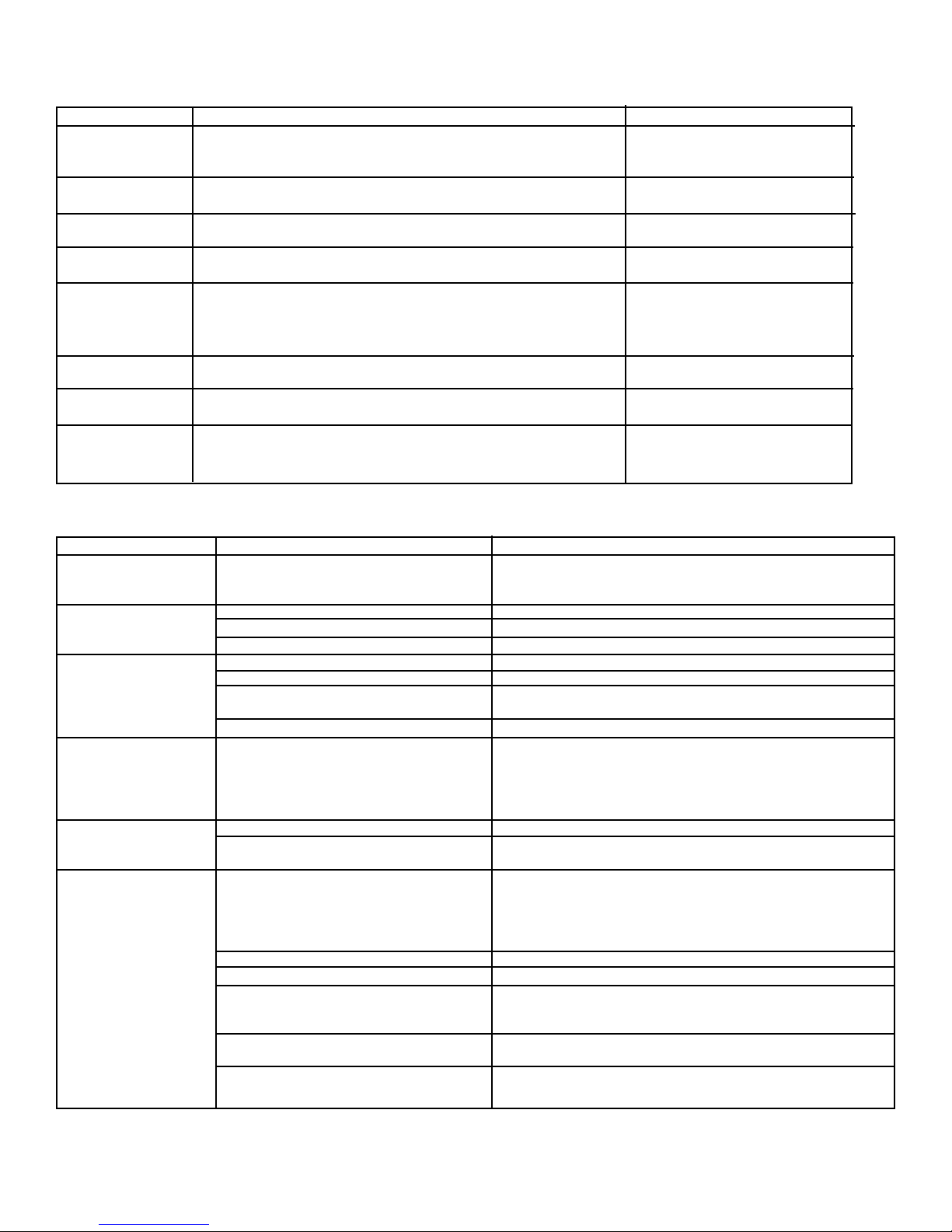

EELLEECCTTRRIICCAALLSSHHOOCCKKHHAAZZAARRDD

PPlluuggiinnttooaaggrroouunnddeedd33--pprroonnggoouuttlleett..

DDOONNOOTTrreemmoovveeggrroouunnddpplluugg..

DDOONNOOTTuusseeaannaaddaapptteerr..

DDOONNOOTTuusseeaanneexxtteennssiioonnccoorrdd..

FFaaiilluurreettooffoolllloowwtthheesseeiinnssttrruuccttiioonnss

ccoouullddrreessuullttiinnffiirreeoorreelleeccttrriiccaallsshhoocckk..

WARNING

Power cord with 3-prong

grounding plug

Grounding-type wall

receptacle

**WWhheenniinnssttaalllliinnggiinnttooaaccuuttoouutt,,tthheeeeddggeeoofftthheeddoooorrmmuussttbbee2277//88””((77..33ccmm))ffrroommtthheeaaddjjaacceennttccoouunntteerrttooppccaabbiinneett..