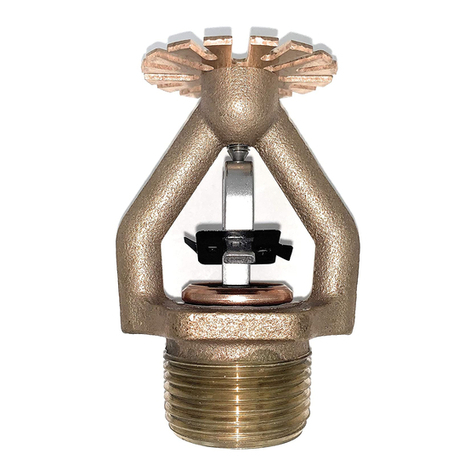

Materials:

Body: Brass Casting UNS-C84400

Deflector: Copper UNS-C19500

Pin: Stainless Steel UNS-C30300

Body Cap: Brass UNS-C26000

Fusible Element: Beryllium Nickel

Seal: Teflon®Tape

Spring: Nickel Alloy

Screw: Brass UNS-C36000

ACCESSORIES: (order separately)

Sprinkler Wrench: Part No. 08336W/B

Ceiling Ring: 3" (76,2 mm) outside di-

ameter,push-on only. BasePartNo.

09390.

Indicate finish when ordering.

5.AVAILABILITYANDSERVICE

Viking sprinklers are available through a

network of Domestic, Canadian, and In-

ternational Distributors. See the Yellow

Pages of the telephone directory (listed

under “Sprinklers - Automatic - Fire”) or

write to The Viking Corporation.

6. GUARANTEES

For details of warranty, refer to Viking’s

current list price schedule or contact Vi-

king directly.

7. INSTALLATION

WARNING: Viking sprinklers are manu-

factured and tested to meet the rigid

requirements of the approving agency.

The sprinklers are designed to be in-

stalled in accordance with recognized

installation standards. Deviation from

the standards or any alteration to the

sprinkler after it leaves the factory in-

cluding, but not limited to, painting, plat-

ing, coating or modification, may render

the sprinkler inoperative and will auto-

matically nullify the approval and any

guarantee madeby TheVikingCorpora-

tion.

A. Sprinklers are to be installed in ac-

cordance with the latest published

standardsoftheNationalFireProtec-

tion Association, Factory Mutual,

LossPrevention Council,Assemblee

Pleniere, Verband der Sachver-

sicherer or other similar organiza-

tions and also with the provisions of

governmentalcodes,ordinancesand

standards whenever applicable. For

conditionsnotspecificallycoveredby

the Standards, refer to the "Viking

Residential Installation Guide". Fi-

nal approval and acceptance of all

Residential Sprinkler Installations

mustbe obtained from the Author-

ity Having Jurisdiction. Residen-

tial sprinklers are generally consid-

ered special service sprinklers for

one and two family dwellings, mobile

homes and residential portions of

other occupancies where allowed.

The use of residential sprinklers may

belimitedduetooccupancyandhaz-

ard. The minimum flow rate indicated

must be provided at the sprinkler,

therefore, the system piping must be

hydraulically calculated. Refer to the

Authority Having Jurisdiction prior to

installation.

B.Sprinklersmustbehandledwithcare.

Horizon® Model H-3 Residential

Flush sprinklers are provided with a

plastic protective shell which should

remain in place over the sprinkler

body during installation, testing, and

any time the sprinkler is handled or

shipped. The plastic protective shell

must be removed prior to placing the

system in service. See paragraph

"F" below. Prior to installation, sprin-

klers must be stored in a cool, dry

place in their original shipping con-

tainer. Never install sprinklers that

have beendropped, damaged inany

way, or have been exposed to tem-

peratures in excess of maximum am-

bient temperature allowed. Such

sprinklers should be destroyed im-

mediately.

C. Corrosion resistant sprinklers must

beinstalledwhensubjecttocorrosive

atmospheres. Viking Horizon®sprin-

klers are not intended for use in cor-

rosive environments.

D. Use care when locating sprinklers

near fixtures that can generate heat.

Do not install sprinklers where they

will be exposed to temperatures that

exceed the maximum recommended

ambient temperature for the tem-

perature rating used.

E. Sprinklers must be protected from

mechanical damage. Wet pipe sys-

temsmustbeprovidedwithadequate

heat.

F. The sprinklers must be installed after

the piping is in place to prevent me-

chanical damage. Before installing,

make sure the appropriate model,

style, orifice size, and temperature

rating with the desired response

characteristic is used. Install the

sprinklers according to the following

steps:

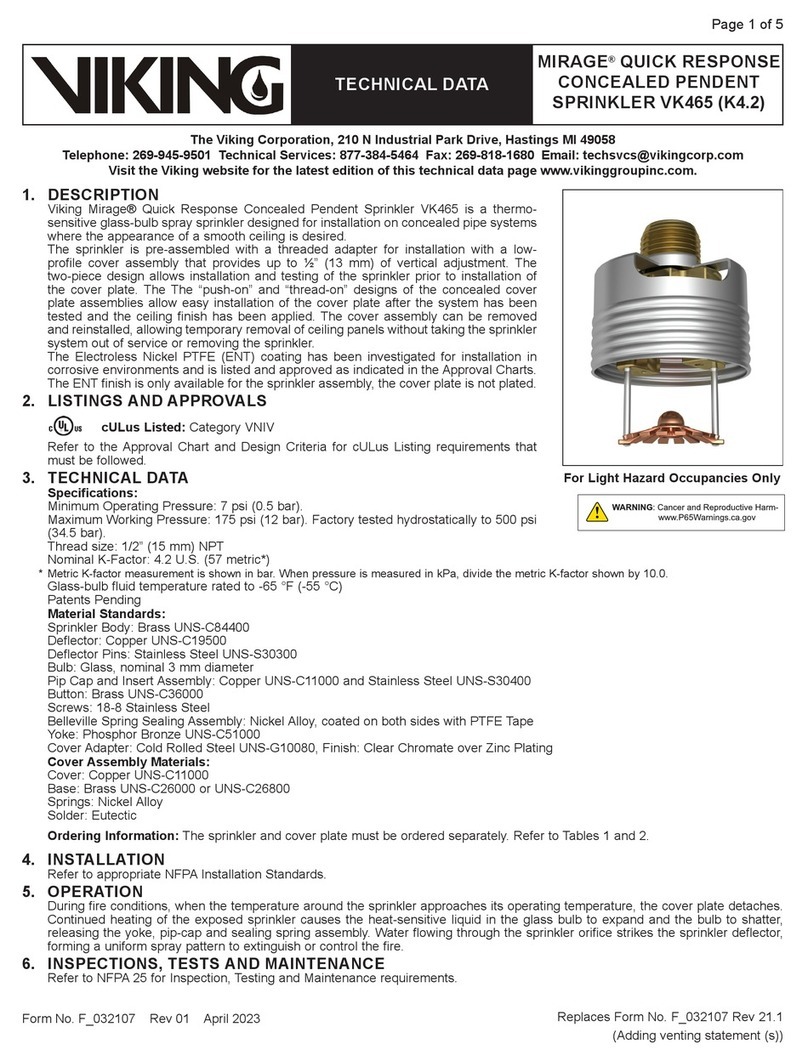

Step 1: Install all piping and cut the

sprinkler drop nipple to position

the 1/2" (15mm) NPT outlet of the

reducing coupling at the desired

elevation. The drop nipple must

beperpendiculartotheceilingand

centered in a 2" (50mm) diame-

ter opening in the ceiling.

Step2: Withthesprinklerintheplas-

tic protective shell, apply a small

amount of pipe joint compound or

tape to the external threads ofthe

sprinkler only.

Step 3: Use only the special wrench*

designed for installing Viking Ho-

rizonSprinklers. With the sprinkler

in the plastic protective shell,

place the unit into the wrench.

* Sprinkler Wrench PN 08336W/B is required.

Previous Viking Horizon Flush Sprinkler

Wrenches appear similar, but were manufac-

tured with a larger outside diameter.

A 1/2" ratchet is required (not available from

Viking).

Step 4: Turn the unit clockwise to

thread the sprinkler into the 1/2"

(15mm) NPT outlet of the cou-

pling. DONOTusethefusiblelink

to start or thread the sprinkler into

a fitting.

G. After installation, the entire system

must be tested in accordance with

Figure A

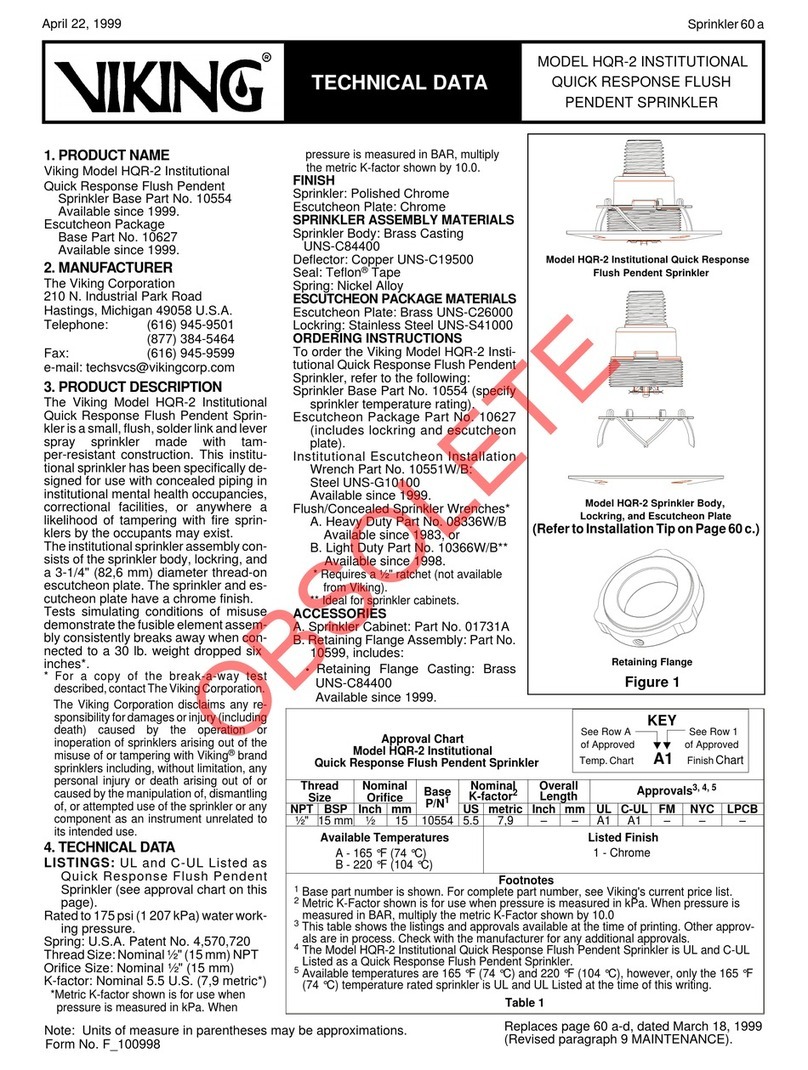

TECHNICAL DATA HORIZON®MODEL H-3

RESIDENTIAL PENDENT

SPRINKLER 3.8 K-FACTOR

June 9, 1997

Sprinkler 145 b

Form No. 062395

R

** A 1/2" ratchet is

required. (Not

available from Viking).

2" (50mm)

diameter

hole required.

Sprinkler

Wrench**

Part No.

08336W/B

VIKING

HORIZON®

Model H-3

Residential

Flush Pendent

Sprinkler

Protective

Cap