TFP460

Page 3 of 8

Operation

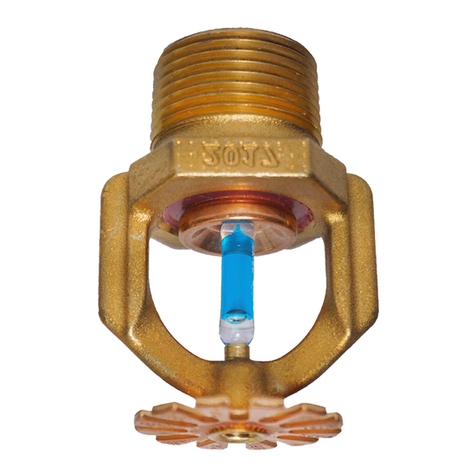

When the TYCO RAPID RESPONSE

Series LFII Dry Type Residential Sprin-

kler (TY2235) is in service, water is pre-

vented from entering the assembly by

the Plug with Sealing Assembly (Figure

1) in the Inlet of the Sprinkler.

The glass Bulb contains a uid that

expands when exposed to heat. When

the rated temperature is reached, the

uid expands sufciently to shatter the

glass Bulb to release the Bulb Seat.

The system’s water or air pressure is

then able to unseat the Plug with Seal-

ing Assembly. The Plug Spring turns

the Plug with Sealing Assembly aside,

allowing the sprinkler to activate and

ow water.

Design

Criteria

The TYCO RAPID RESPONSE Series

LFII Dry Type Residential Recessed

Pendent Sprinklers (TY2235) are UL

Listed for installation in accordance

with this section:

Residential Sprinkler Design Guide

When conditions exist that are out-

side the scope of the criteria provided

in this section, refer to the technical

data sheet entitled Residential Sprin-

kler Design Guide (TFP490) for the

manufacturer’s recommendations

that may be acceptable to the local

authority having jurisdiction.

System Types

Wet pipe and dry pipe systems may be

utilized. Refer to Technical Data Sheet

TFP485 for the use of residential sprin-

klers in residential dry pipe systems.

Ceiling Types

Smooth at horizontal, or beamed, or

sloped, in accordance with the 2013

Edition of NFPA 13D, 13R, or 13 as

applicable.

Hydraulic Design

(NFPA 13D and 13R)

For systems designed to NFPA 13D

or NFPA 13R, the minimum required

sprinkler ow rate are given in Tables

A or B as a function of temperature rat-

ing and the maximum allowable cov-

erage areas. The sprinkler ow rate is

the minimum required discharge from

each of the total number of “design

sprinklers,” as specied in NFPA 13D

or NFPA 13R. The number of “design

sprinklers” specied in NFPA 13D and

13R for wet pipe systems is to be ap-

plied when designing dry pipe systems.

Hydraulic Design

(NFPA 13)

For systems designed to NFPA 13, the

number of required design sprinklers is

the four most hydraulically demanding

sprinklers. The minimum required dis-

charge from each of the four sprinklers

is the greater of the following:

•

ow rates listed in Table A or B as a

function of temperature rating and the

maximum allowable coverage area.

•

minimum discharge of 0.1 gpm/ft2over

the design area comprised of the four

most hydraulically demanding sprin-

klers for the actual coverage areas

protected by four sprinklers.

The number of “design sprinklers”

specied in NFPA 13 for wet pipe sys-

tems is to be applied when designing

dry pipe systems.

Dry Pipe System Water Delivery

When using the Series LFII Residential

Sprinklers (TY2235) in dry pipe sprin-

kler systems, the time for water deliv-

ery must not exceed 15 seconds for

the most remote operating sprinkler.

Obstruction to Water Distribution

Sprinklers are to be located in accor-

dance with the obstruction rules of

NFPA 13D, 13R, and 13 as applicable

for residential sprinklers as well as

with the obstruction criteria described

within the TYCO Technical Data Sheet

TFP490.

Operational Sensitivity

The sprinkler must be located relative

to the mounting surface as shown in

Figure 2.

Sprinkler Spacing

The minimum spacing between sprin-

klers is 8 feet (2,4 m). The maximum

spacing between sprinklers cannot ex-

ceed the length of the coverage area

(Table A) being hydraulically calculated

(e.g., a maximum of 12 feet for a 12 ft. x

12 ft. coverage area or 20 feet for a 20

ft. x 20 ft. coverage area.)

Sprinkler Fittings

The following ttings may be used:

•

The 1 inch NPT outlet or run of a mal-

leable or ductile iron threaded tee

ttings that meet the dimensional re-

quirements of ANSI B16.3 (Class 150)

•

The 1 inch NPT outlet or run of a cast

iron threaded tee ttings that meet

the dimensional requirements of ANSI

B16.4 (Class 125).

For dry pipe systems, only use the

side outlet of maximum 2-1/2 inch

size reducing tees when locating

the Series LFII Dry Type Residen-

tial Recessed Pendent Sprinklers

directly below the branch line. Oth-

erwise, use the conguration shown

in Figure 5 to assure complete

drainage from above the Series

LFII Sprinklers and the branch line.

Do not install the Series LFII Dry

Type Residential Recessed Pen-

dent Sprinklers into elbow ttings.

The Inlet of the sprinkler can con-

tact the interior of the elbow, po-

tentially damaging the Inlet seal.

Only use the conguration in Fig-

ure 4 where the sprinkler tting and

water-lled pipe above the sprinkler

tting are not subject to freezing and

where the length of the Series LFII

Sprinkler has the minimum exposure

length per Figure 6. Refer to the Ex-

posure Length section and Table C.

•

The 1 inch NPT outlet of a GRINNELL

Figure 730 Mechanical Tee in wet pipe

systems only

•

The 1 inch NPT CPVC outlet of a 1” x 1”

x 1” NPT Sprinkler Head Adapter Tee

(P/N 80249) in wet pipe systems only

•The 1 inch NPT CPVC outlet of a 1” x

1” NPT Female Adapter (P/N 80145)

in wet pipe systems only

•

The 1 inch NPT outlet of a 1” x 1” x 1”

NPT CPVC Sprinkler Head Adapter

Tee (P/N 80259) in either wet or dry

pipe systems

NOTICE

Do not install the Series LFII Dry Type

Residential Recessed Pendent Sprin-

klers into any other type fitting without

first consulting the Technical Services

Department. Failure to use the appro-

priate fitting may result in the following:

• failure of the sprinkler to operate

properly due to formation of ice over

the Inlet Plug or binding of the Inlet

Plug.

• insufcient engagement of the in-

let pipe threads with consequent

leakage.

Drainage

Branch, cross, and feed-main piping

connected to Series LFII Dry Type Res-

idential Recessed Pendent Sprinklers

and subject to freezing temperatures

must be pitched to allow proper drain-

age, in accordance with the minimum

requirements of the National Fire Pro-

tection Association for dry pipe sprin-

kler systems.

Exposure Length

When using Series LFII Dry Type Resi-

dential Recessed Pendent Sprinklers in

wet pipe sprinkler systems to protect

areas subject to freezing temperatures,

use Table C to determine a sprinkler’s

appropriate exposed barrel length to

prevent water from freezing in the con-

necting pipes due to conduction. The

exposed barrel length measurement