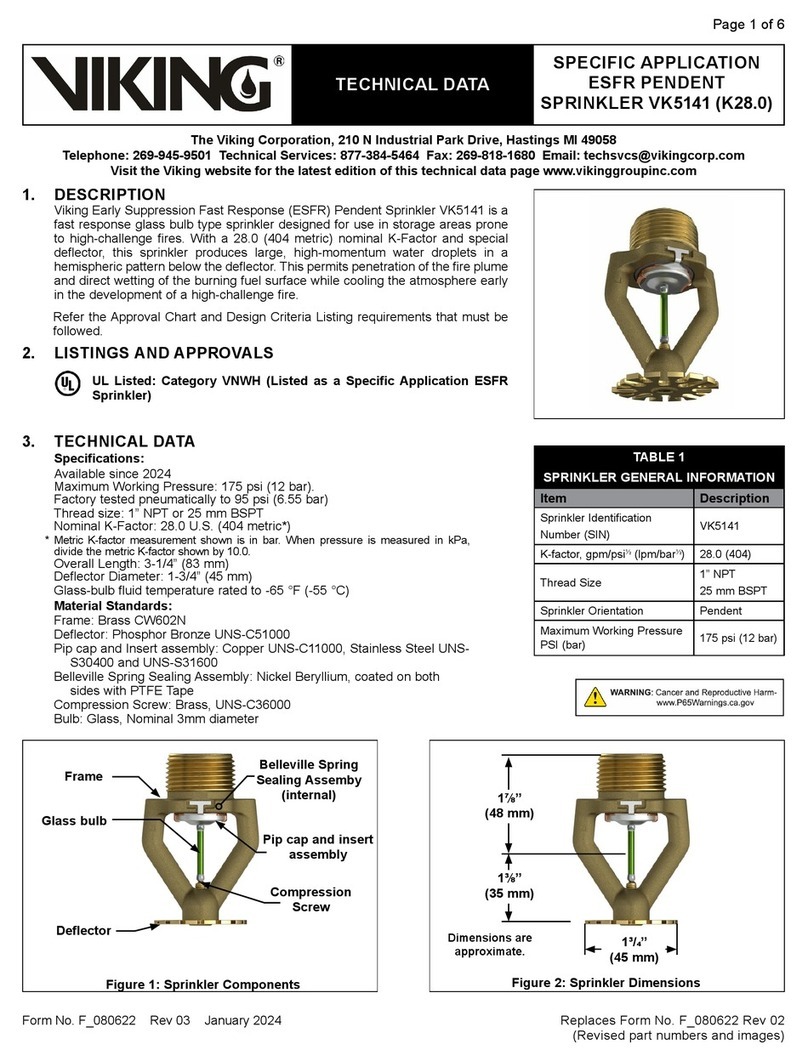

Thread Size: 3/4" (20 mm) NPT

Deflector Diameter: 1-3/4" (44,45 mm)

Overall Length: 2-7/8" (73 mm)

SPRINKLER MATERIALS

Frame: Brass Casting UNS-C84400

Seat: Stainless Steel UNS-S31603

Belleville Spring Sealing Assembly:

Nickel Alloy, coated on both sides

with Teflon Tape

Screw: Stainless Steel UNS-S31603

Deflector: Bronze UNS-C51000

Trigger and Support: Stainless Steel

UNS-S31600

Fusible Element Assembly: Beryllium

Nickel, coated with black acrylic

paint.

Ejector Spring (Sprinkler Base Part No.

11350 only): 17-7 Stainless Steel

AVAILABLE FINISH: Brass

ACCESSORIES

Sprinkler Wrench: Part No. 10285W/B

Size: Fits 3/4" NPT ESFR Pendent

Sprinklers

Available since 2000.

Sprinkler Cabinet: Part No. 01725A

Capacity: twelve (12) sprinklers

Length: 10-3/16" (259 mm)

Height: 8-9/16" (217 mm)

Depth: 2-9/16" (65 mm)

5. AVAILABILITY & SERVICE

Viking products are available through a

network of domestic, Canadian, and

international distributors. See the Viking

Corp. Web site for your closest distribu-

tor or contact The Viking Corporation.

Viking technical data may be found on

The Viking Corporation’s Web site at

http://www.vikingcorp.com.

The Web site may include a more recent

edition of this technical data page.

6. GUARANTEES

For details of warranty, refer to Viking’s

currentlistpricescheduleorcontactThe

Viking Corporation directly.

7. DESIGN & INSTALLATION

WARNING: Viking sprinklersare manu-

factured and tested to meet rigid re-

quirements of the approving agency.

The sprinklers are designed to be in-

stalled in accordance with recognized

installation standards. Deviation from

the standards or any alteration to the

sprinkler after it leaves the factory in-

cluding, but not limited to: painting, plat-

ing,coating,ormodification, mayrender

the sprinkler inoperative and will auto-

matically nullify the approval and any

guaranteemadebyTheVikingCorpora-

tion.

A. Viking ESFR Pendent SIN VK500

Sprinklersaretobeinstalledinaccor

-

dance with applicable FM Global

LossPreventionData Sheets,the lat-

est standards of Verband der

Sachversicherer, LPCB, and the Na

-

tionalFireProtectionAssociation, the

Authorities Having Jurisdiction, and

also with the provisions of govern-

mental codes, ordinances, and stan

-

dards whenever applicable.

B.Sprinklersmustbehandledwithcare.

They must be stored in a cool, dry

place in their original shipping con

-

tainer. Never install sprinklers that

have been dropped or damaged in

any way. (Such sprinklers should be

destroyed immediately.) Wet-pipe

systems must be provided with ade-

quate heat.

C. The sprinklers must be installed after

the piping is in place to prevent me

-

chanical damage. Before installing,

besureto havetheappropriate sprin-

kler model and style, with the correct

orifice size, temperature rating, and

response characteristics.

D. With the sprinkler contained in the

plastic protective cap, apply a small

amount of pipe-joint compound or

tape to the male threads only, while

taking care not to allow a build-up of

compound in the sprinkler orifice.

E. With the sprinkler contained in the

plastic protective cap, install the

sprinkler onto the piping by apply-

ing the special sprinkler wrench

(showninFigure 1) to the sprinkler

wrench flats only, while taking

care not to damage the sprinkler

operating parts. DO NOT use any

other type of wrench, as this could

damage the unit. DO NOT use the

sprinkler deflector or fusible

element to start or thread the

sprinkler into a fitting. DO NOT ex

-

ceed 50 ft. lbs. of torque (hand

tight, plus approximately two full

turns with the wrench) to install

these sprinklers. Higher levels of

torquemay distort the sprinkler in-

let with consequent leakage or im-

pairment of the sprinkler.

F. Use only the special sprinkler wrench

and immediately replace any dam-

aged units.

G. After installation, the entire sprinkler

systemmustbetested.Thetestmust

be conducted to comply with the In-

stallation Standards.

Make sure the sprinkler has been

properly tightened. If a thread leak

occurs, normally the unit must be re-

moved, new pipe-joint compound or

tape applied, and then reinstalled.

This is due to the fact that when the

joint seal is damaged, the sealing

compound or tape is washed out of

the joint.

H. After installation and testing and

repairing of all leaks, remove the

plastic protective cap from the

sprinkler. THE CAP MUST BE RE-

MOVED FROM THE SPRINKLER

BEFORE PLACING THE SYSTEM

IN SERVICE.

I. System design must be based on

ESFR design guidelinesdescribed in

applicable FM Global Loss Preven-

tionDataSheets,thelateststandards

of Verband der Sachver- sicherer,

LPCB, the National Fire Protection

Association,and theAuthorities Hav-

ing Jurisdiction. All requirements of

recognized sprinkler system design

standards apply to systems utilizing

Viking ESFR Pendent Sprinklers.

NOTE:Vikingrecommendsinstall

-

ing one style of sprinklers (either

pendent or upright) throughout

ESFRsystems.However,provided

the fusible elements are installed

within the distance below the ceil-

ing allowed by the installation

standards, and when acceptable

to the AHJ, Viking considers the

practice of mixing upright and

pendent ESFR sprinklers to be ac-

ceptable.

8. MAINTENANCE

NOTICE: The owner is responsible for

maintaining the fire protection system and

devices in proper operating condition. For

minimum maintenance and inspection re-

quirements, refer to the NFPA standard

that describes care and maintenance of

sprinkler systems. In addition, the Author-

ities Having Jurisdiction may have addi-

tionalmaintenance,testing,andinspection

requirements that must be followed.

A.Thesprinklersmustbeinspectedona

regular basis for corrosion, mechani

-

cal damage, obstructions, paint, etc.

The frequency of inspections may

vary due to corrosive atmosphere,

water supplies, and activity around

the device.

B. Sprinklers that have been painted or

mechanically damaged must be re-

placedimmediately.Sprinklersshow

-

ing signs of corrosion shall be tested

and/or replaced immediately as re-

quired. Installation standards require

Sprinkler120c

TECHNICAL DATA ESFR PENDENT SPRINKLERS

SIN VK500 (K = 14.0)

December 10, 2004