Do not install sprinklers where they

will be exposed to temperatures that

exceed the maximum recommended

ambient temperature for the temper-

ature rating used.

E. Sprinklers must be protected from

mechanical damage. Adequate heat

must be provided when sprinklers

are installed on wet-pipe systems.

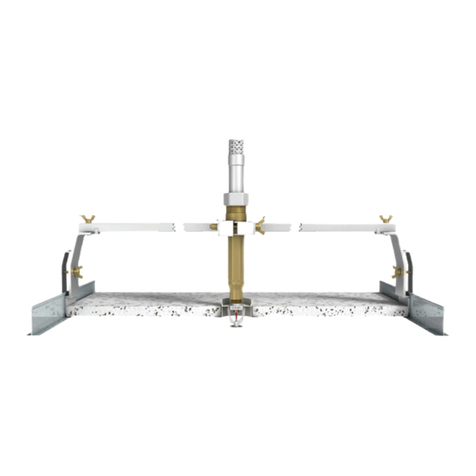

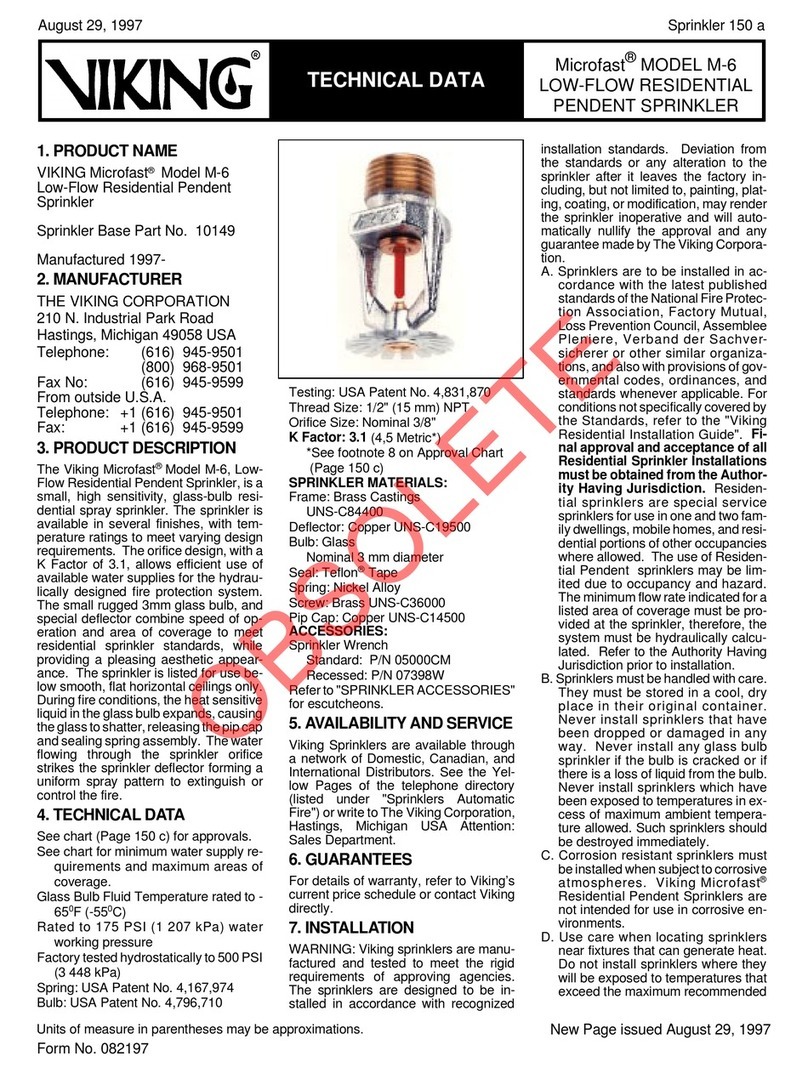

F. The Microfast®Model M-7 Low-Flow

Residential Horizontal Sidewall

Sprinkler must be installed after the

pipingisin placetoprevent mechani-

cal damage, and must be installed

only below smooth, flat, horizontal

ceilings. Refer to approval chart on

page 151 c for allowable deflector

distance below the ceiling, and note

minimumwatersupplyrequirements.

The top of the horizontal sidewall de-

flector must be aligned parallel to the

ceiling.

Before installation, be sure to have

the appropriate sprinkler model and

style, with the correct orifice size,

temperature rating, and response

characteristics.

1. Install escutcheon (if used), which

is designed to thread onto the ex-

ternal threads of the sprinkler.

Refer to the “Sprinkler Acces-

sories” section of the V iking Engi-

neering and Design Databook for

technical data on approved es-

cutcheonsandotheraccessories.

2. Apply a small amount of pipe-joint

compound or tape to the external

threads of the sprinkler only, tak-

ing care not to allow a build-up of

compound in the sprinkler inlet.

3. Care must be taken when install-

ing sprinklers on CPVC and cop-

per piping systems. Never install

the sprinkler into the reducing fit-

ting before attaching the reducing

fitting to the piping.

Sprinklers must be installed on

CPVC systems after the reducing

fitting has been installed and the

primer and/or cement manufac-

turer’s recommended curing time

has elapsed.

When installing sprinklers on cop-

per piping systems, take care to

brush the inside of the sprinkler

supply piping and reducing fitting

toensurethatnofluxaccumulates

inthe sprinklerorifice. Excess flux

can cause corrosion and may im-

pair the ability of the sprinkler to

operate properly.

4. Install the sprinkler on the piping

usingthe special sprinklerwrench

only, taking care not to over-

tighten or damage the sprinkler

operating parts. DO NOT use the

sprinkler deflector to start or

thread the sprinkler into a fitting.

G. After installation, the entire sprinkler

systemmustbetestedinaccordance

with the recognized installation stan-

dards. The test is applied after sprin-

kler installation to ensure that no

damagehasoccurredtothesprinkler

during shipment and installation, and

to make sure the unit has been prop-

erlytightened.Ifathreadleakoccurs,

normally the unit must be removed,

new pipe-joint compound or tape ap-

plied, and then reinstalled. This is

duetothefactthatwhenthejointseal

leaks, the sealing compound is

washed out of the joint.

8. MAINTENANCE

NOTICE: The owner is responsible for

maintaining the fire-protection system

and devices in proper operating condi-

tion. For minimum maintenance and in-

spection requirements, refer to the Na-

tional Fire Protection Association’s

pamphlet that describes care and main-

tenance of sprinkler systems. In addi-

tion, the Authority Having Jurisdiction

may have additional maintenance, test-

ing, and inspection requirements that

must be followed.

A.Thesprinklersmustbeinspectedona

regular basis for signs of corrosion,

mechanical damage, obstructions,

paint, etc. The frequency of the in-

spections may vary due to corrosive

atmospheres, water supplies, and

activity around the device.

B. Sprinklers that have been field

painted, caulked, or mechanically

damaged must be replaced immedi-

ately. Sprinklers showing signs of

corrosion shall be tested and/or re-

placed immediately as required.

Microfast® Residential Sprinklers

that are 20 years old shall be tested

and/or replaced immediately as re-

quired. Never attempt to repair or re-

assemble a sprinkler. Sprinklers that

have operated cannot be reassem-

bled or re-used, but must be re-

placed. When replacing sprinklers,

useonlynewsprinklerswithidentical

performance characteristics.

C. The sprinkler discharge pattern is

critical for proper fire protection.

Nothing should be hung from, at-

tached to, or otherwise obstruct the

discharge pattern of the sprinkler. All

obstructionsmustbeimmediatelyre-

moved or, if necessary, additional

sprinklers installed.

D. When replacing existing sprinklers,

the system must be removed from

service.Refertotheappropriate sys-

tem description and/or valve instruc-

tions. Prior to removing the system

from service, notify all Authorities

Having Jurisdiction. Consideration

should be given to employment of a

fire patrol in the effected area.

1. Remove the system from service,

drain all water, and relieve all

pressure on the piping.

2. Using the special sprinkler

wrench, remove the old sprinkler

and install the new unit. Care

must be taken to ensure that the

replacement sprinkler is the

proper model and style, with the

correct orifice size, temperature

rating, and response characteris-

tics.A fully stockedsprinkler cabi-

net should be provided for this

purpose.

3. Place the system back in service

and secure all valves. Check and

repair all leaks.

E. Sprinkler systems that have been

subjected to a fire must be returned

to service as soon as possible. The

entire system must be inspected for

damage,andrepairedorreplacedas

necessary. Sprinklers that have

been exposed to corrosive products

of combustion or high ambient tem-

peratures, but have not operated,

should be replaced. Refer to the Au-

thority Having Jurisdiction for mini-

mum replacement requirements.

May 27, 1999Sprinkler 151 b

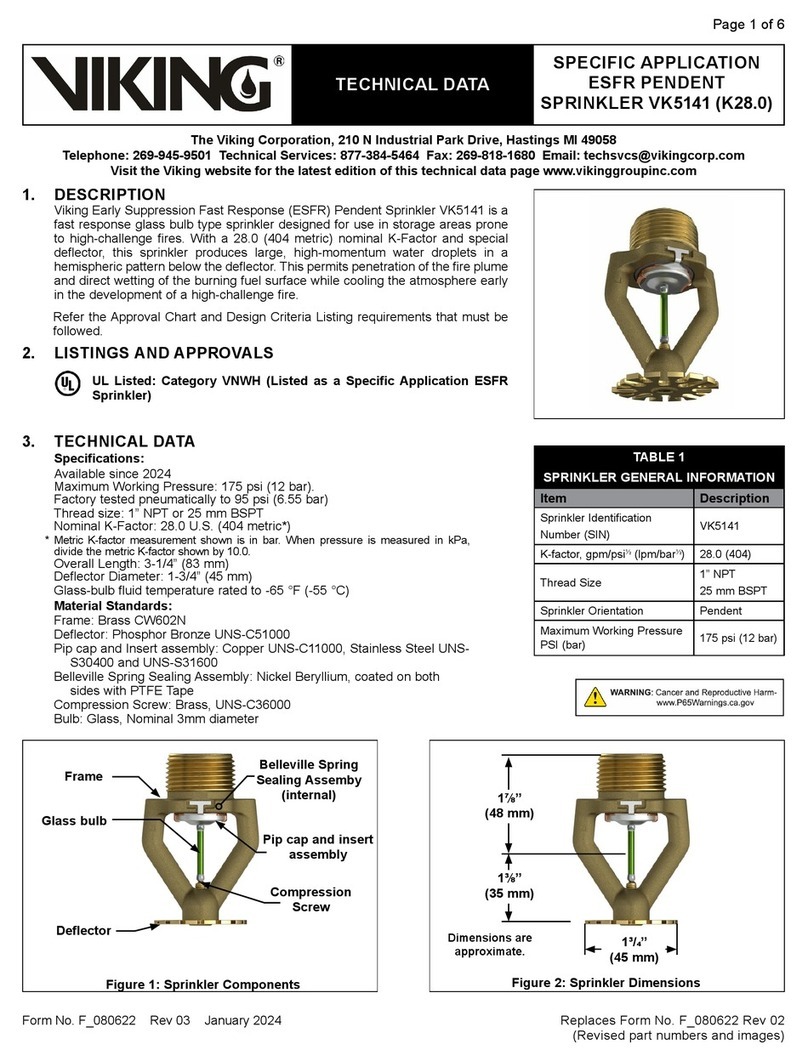

TECHNICAL DATAMicrofast ®MODEL M-7

LOW-FLOW RESIDENTIAL

HORIZONTAL SIDEWALL

SPRINKLER