Viking Technical Data may be found on

The Viking Corporation’s Web site at

http://www.vikingcorp.com

The Web site may include a more recent

edition of this Technical Data page.

6. GUARANTEES

For details of warranty, refer to Viking’s

current list price schedule or contact

The Viking Corporation directly.

7. INSTALLATION

WARNING:Viking sprinklersare manu-

factured and tested to meet the rigid re-

quirements of approving agencies. The

sprinklersaredesignedtobeinstalledin

accordance with recognized installation

standards.Deviationfromthestandards

or any alteration to the sprinkler after it

leaves the factory including, but not lim-

ited to: painting, plating, coating, or

modification, may render the sprinkler

inoperative and will automatically nullify

the approval and any guarantee made

by The Viking Corporation.

A.Sprinklersare tobe installedin accor-

dance with the latest published stan-

dards of the National Fire Protection

Association, Factory Mutual, Loss

Prevention Council, Assemblee

Pleniere, Verband der

Sachversicherer or other similar or-

ganizations, and also with provisions

of governmental codes, ordinances,

and standards whenever applicable.

The use of dry sidewall sprinklers

may be limited due to occupancy and

hazard. RefertotheAuthorityHaving

Jurisdiction prior to installation.

B.Sprinklersmustbehandledwithcare.

They must be stored in a cool, dry

place in their original container.

Never install sprinklers that have

been dropped or damaged in any

way. Never install a glass-bulb sprin-

kler if the bulb is cracked or if there is

alossofliquidfromthebulb.Ifaglass

bulb lacks the appropriate amount of

fluid, it should be set aside and re-

turned to Viking (or an authorized Vi-

king distributor) for analysis as soon

as possible. If the sprinkler is not re-

turned to Viking, it should be de-

stroyed immediately. Never install

sprinklers that have been exposed to

temperatures in excess of maximum

ambient allowed (these sprinklers

should be destroyed immediately).

C. Viking Model M Dry Sidewall Sprin-

klers are not intended for use in cor-

rosive environments. Use only sprin-

klers listed for corrosive environ-

ments when subject to corrosive at-

mospheres.

WARNING: Model M Dry Horizontal

Sidewall Sprinklers MUST be in-

stalled into the 1" outlet of a cast iron

ormalleableironteestylefittingonly.

The threaded end of the dry sidewall

sprinkler is designed to allow the seal to

penetrate and extend into the fitting to a

predetermined depth. This prevents

condensation from accumulating and

freezing over the sprinkler seal.

1. DO NOT install the dry sidewall

sprinklers into a threaded elbow,

coupling, or any other fitting that

could interfere with thread pene-

tration. Such installation would

damage the brass seal.

2. DO NOT install the dry sidewall

sprinkler into a coupling or fitting

that would allow condensation to

accumulate above the seal, when

locatedin an areasubjecttofreez-

ing.

3. NEVER try to modify the dry side-

wall sprinkler. The sprinklers are

manufactured for a specific “A” di-

mensionandcannotbemodified.

D. The sprinkler must be installed after

the piping is in place to prevent me-

chanicaldamage.Before installation,

besuretohavetheappropriatesprin-

kler model and style, with the correct

orifice size, temperature rating, re-

sponse characteristics, and “A” di-

mension. Apply a small amount of

pipe-joint compound or tape to the

male threads only, taking care not to

allow a build-up of compound over

the brass inlet and seal. Install the

sprinkler onto the piping using the

special dry sprinkler wrench only,

while taking care not to damage the

sprinkler.DONOTuse apipe wrench

onthe barrel ofthedrysidewallsprin-

kler.

E. After installation, the entire sprinkler

systemmust betested inaccordance

with the recognized installation stan-

dards. The test is applied after sprin-

kler installation to ensure that no

damagehasoccurredtothe sprinkler

during shipment and installation, and

to make certain the unit has been

properly tightened. If a thread leak

occurs, normally the unit must be re-

moved, new pipe-joint compound or

tape applied, and then reinstalled.

This is due to the fact that when the

joint seal leaks, the sealing com-

pound is washed out of the joint.

F. Wet pipe systems supplying dry side-

wall sprinklers must be provided with

adequate heat. Refer to appropriate

installation standards.

8. MAINTENANCE

NOTICE:The owner is responsible for

maintaining the fire protection system

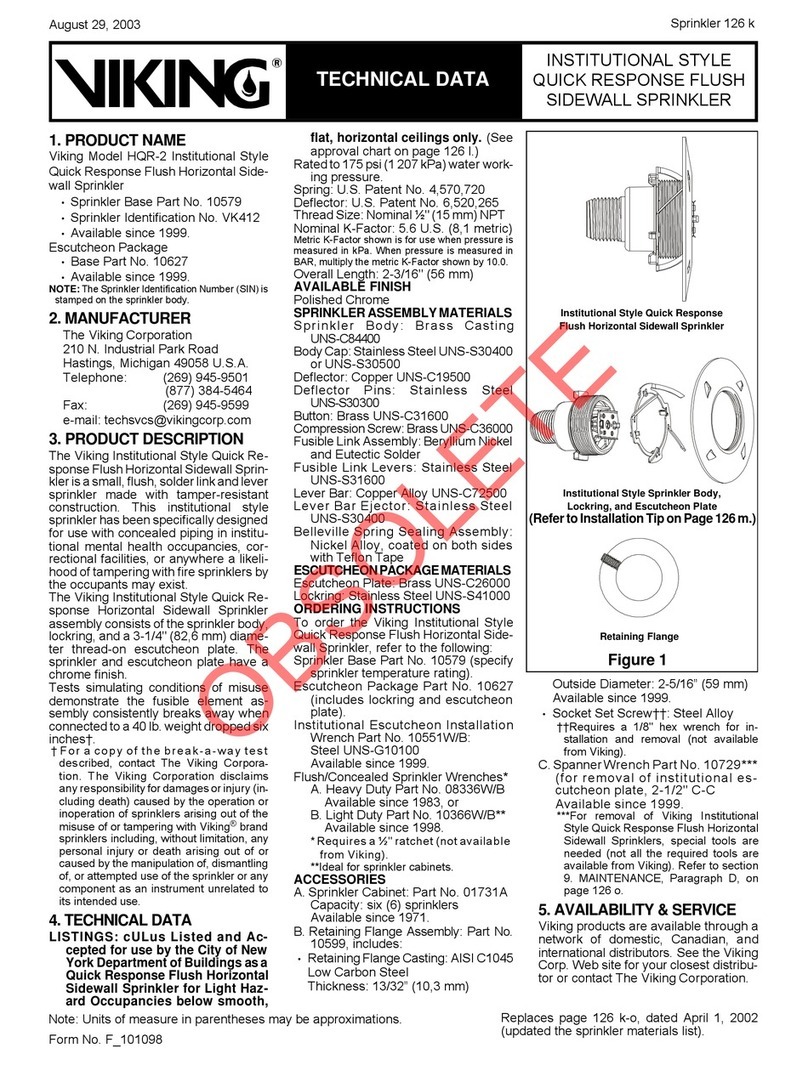

Sprinkler 109 bMarch11,1999

Available

Adjustment:

1-7/8" (47,6 mm)

minimum

1/2" (12,7 mm)

3-1/16"

(77,8 mm)

4" (102 mm) minimum

12" (305 mm) maximum

For “A” dimension:

1. Determine the distance from face of tee

to face of finished wall.

2. Round to nearest 1/4" (6,35 mm) between

3-1/4" (82,5 mm) and 48" (1 219,2 mm).

NOTE:The sprinkler will be recessed approx-

imately 5/16" (7,9 mm) with 5/8"

(15,8 mm) horizontal adjustment.

Minimum ceiling hole size:

2-1/8" (54 mm) diameter.

Ceiling

Wall

5/16" (7,9 mm) outward

and inward adjustment

Figure A

Model M Adjustable Recessed

Dry Horizontal Sidewall

Sprinkler

TECHNICAL DATAMODEL M

QUICK RESPONSE

EXTENDED COVERAGE

DRY SIDEWALL SPRINKLER