Factory tested pneumatically at 100 PSI

(685 kPa).

Spring: USA Patent No. 4,167,974

Bulb: USA Patent No. 4,796,710

SPRINKLER MATERIALS:

Frame: Brass Castings

UNS-C84400

Deflector: Brass

UNS-C26000

Bulb: Glass,

Nominal 3mm diameter

Seal: Teflon Tape

Spring: Nickel Alloy

Screw: Brass

UNS-C36000

Pip Cap: Brass

UNS-C31600

Seat: Copper

UNS-C21000

Orifice: Copper

UNS-C21000

Washer: Stainless Steel

UNS-S30400

Base: Brass UNS-C31600

Gasket: Buna N

Tube: JIC Hydraulic Steel Tube

Inlet: Brass UNS-C36000

Support (Internal): Steel UNS-G10080

Electrodeposited

Epoxy Base finish

Spring (Internal when "B" dimension

exceeds 37" (940mm):

Stainless Steel UNS-S30200

Barrel: Steel Tube

UNS-G10200

Electrodeposited

Epoxy Base finish (Black)

ESCUTCHEON MATERIAL:

Escutcheon: Brass UNS-C26000

(Decorative Chrome Finish)

ACCESSORIES:

Dry Sprinkler Wrench

Standard: PN 07297

Escutcheon: PN 01964B

Decorative Brass finish

(A chrome escutcheon is included

witheachModelMDryUprightSprin-

kler)

SPRINKLER FINISHES:

Plain Barrel with Brass Sprinkler

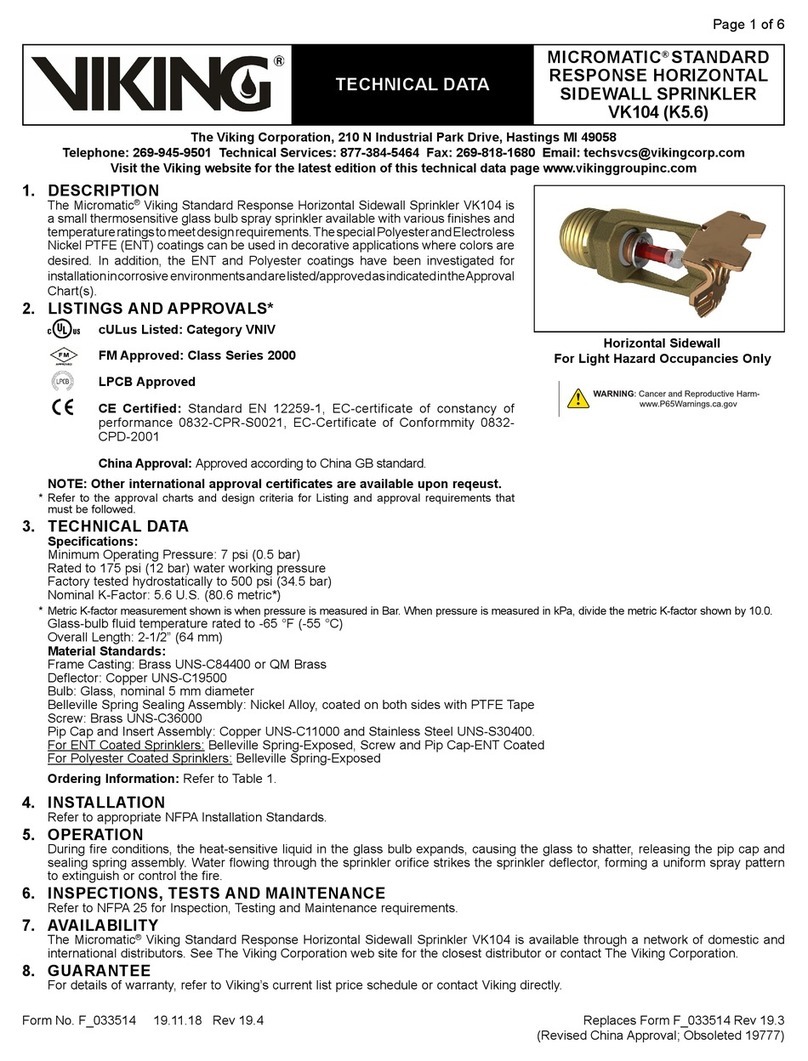

ORDERING INFORMATION:

Forpropershipmentspecify: model,fin-

ish, temperature rating, and length ("B"

Dimension) desired. Viking Dry Upright

Sprinklers are ordered in specific

lengthsnotedas the "B" dimension (see

Figure 1). For Viking Model M Dry Up-

right Sprinklers the "B" dimension is the

distance from the face of the fitting (tee),

into which the sprinkler is to be installed,

to thetop of the deflector(see Figure1).

5. AVAILABILITYANDSERVICE:

Viking Sprinklers are available through

a network of Domestic, Canadian, and

International Distributors. See the Yel-

low Pages of the telephone directory

(listed under "Sprinklers Automatic

Fire")or contactTheVikingCorporation.

6. GUARANTEES

For details of warranty, refer to Viking’s

current list price schedule or contact Vi-

king directly.

7. INSTALLATION

WARNING: Viking sprinklers are manu-

factured and tested to meet the rigid

requirements of approving agencies.

The sprinklers are designed to be in-

stalled in accordance with recognized

installation standards. Deviation from

the standards or any alteration to the

sprinkler after it leaves the factory in-

cluding, but not limited to, painting, plat-

ing, coating, or modification, may render

the sprinkler inoperative and will auto-

matically nullify the approval and any

guarantee madeby TheVikingCorpora-

tion.

A. Sprinklers are to be installed in ac-

cordance with the latest published

standardsoftheNational FireProtec-

tion Association, Factory Mutual,

Loss Prevention Council, Assemblee

Pleniere, Verband der Sachver-

sicherer or other similar organiza-

tions,andalso with provisionsofgov-

ernmental codes, ordinances, and

standards whenever applicable. The

use of Quick Response Dry Upright

Sprinklers may be limited due to oc-

cupancy and hazard. Refer to the

Authority Having Jurisdiction prior to

installation.

B. Sprinklers must behandled withcare.

They must be stored in a cool, dry

place in their original container.

Never install sprinklers that have

been dropped or damaged in any

way. Never install any glass bulb

sprinkler if the bulb is cracked or if

there is a loss of liquid from the bulb.

Never install sprinklers which have

been exposed to temperatures in ex-

cess of maximum ambient tempera-

ture allowed. Such sprinklers should

be destroyed immediately.

C. Model M Dry Upright Sprinklers are

not intended for use in corrosive en-

vironments. Use only sprinklers

listed for corrosive environments

when subject to corrosive atmos-

pheres.

WARNING: Dry Upright Sprinklers

MUST be installed into the 1" outlet of

acastironor malleableironteefitting

only.

1. DO NOT install the Dry Upright

Sprinkler into a threaded elbow,

coupling, or any other fitting that

could interfere with thread pene-

tration. Such installation will

damage the brass seal.

2. NEVER try to modify the Dry Up-

right Sprinkler. The sprinklers are

manufactured for a specific "B"

dimension and cannot be modi-

fied.

D.ModelMQuickResponseDryUpright

Sprinklers must be installed after the

pipingis in place topreventmechani-

cal damage. Install the sprinkler

above the piping, in the upright posi-

tion only. Wheninstalling DryUpright

Sprinklers on piping located close to

the ceiling it may be necessary to

lowerthe sprinklerintothe fittingfrom

above the ceiling. Before installing,

verifythatthe"B"dimensioniscorrect

and theappropriate model, style, and

temperature rating is used. When in-

stalling theDry Upright Sprinkler from

below the ceiling, verify that the hole

in the ceiling is a minimum 1-1/2"

(38,1mm) diameter.

1. Install the optional escutcheon (if

used)overthethreadedendofthe

Dry Upright Sprinkler barrel. Slide

the escutcheon past the external

threads.

Note:Wheninstallingthesprinkler

from above the ceiling, it will be

necessary to install the escutch-

eon after lowering the threaded

end of the sprinkler through the

ceiling penetration.

2. Apply a small amount of pipe joint

compound or tape to the external

threads of the sprinkler barrel

only, taking care not to allow a

build up ofcompound or tape over

the brass inlet and seal.

3. Install the sprinkler on the piping

using the special Dry Sprinkler

Wrenchonly,whiletakingcarenot

to damage the sprinkler. DO NOT

use a pipe wrench on the barrel of

the Dry Upright Sprinkler.

E. After installation, the entire sprinkler

systemmustbe testedinaccordance

withtherecognizedinstallationstand-

ards. The test is applied after sprin-

kler installation to insure no damage

has occurred to the sprinkler during

Sprinkler 107 b

TECHNICAL DATA

March 21, 1996

R

MODEL M

QUICK RESPONSE

DRY UPRIGHT

SPRINKLER