During fire conditions, when the tem-

perature around the sprinkler ap-

proaches it’s operating temperature,the

cover plate detaches. Continued heat-

ing of the exposed sprinkler causes the

fusible link to disengage, releasing the

deflector and sealing assembly. Water

flowing through the sprinkler orifice

strikes the deflector, forming a uniform

spray pattern to extinguish or control the

fire.

4. TECHNICAL DATA

Refer to table 1 previous page for ap-

provals.

Rated to 175 PSI (1 207 kPa) water

working pressure

Factory tested pneumatically to 95 PSI

(655 kPa)

Spring: U.S.A. Patent No. 4,570,720.

Thread Size:

P/N 08498: 1/2" (15 mm) NPT

P/N 10485: 3/4" (20 mm) NPT

Orifice Size:

P/N 08498: Nominal 1/2" (15 mm)

P/N 10485: Nominal 17/32" (20 mm)

K Factor:

P/N 08498: 5.5 ( 7,9 Metric*)

P/N 10485: 8.0 (11,5 Metric*)

*Metric K Factor shown is for use when pres-

sure is measured on kPa. When pressure is

measured in BAR, multiply the metric K Fac-

tory shown by 10.0

Minimum operating pressure: 7 PSI

(48,3 kPa)

Maximum distance from sprinklers to

walls: One half the allowable sprin-

klerspacingindicatedintheApproval

Chart for the "Maximum Area ofCov-

erage Length X Width" used.

Available Cover Plate Adjustment:

1/2" (12,7 mm) (+/- 1/4" [6,4 mm])

Sprinkler Materials:

Body: Brass Casting UNS-C84400

Body Cap: Brass UNS-C26000

Deflector: Copper UNS-C19500

Deflector Pins: Stainless Steel UNS-

S30300

Lever Bar: Copper Alloy UNS-C72500

Compression Screw: Brass UNS-

C36000

Fusible Link Assembly*: Nickel Alloy

and Eutectic Solder

* Fusible links of Viking Extended Coverage Hori-

zon®Mirage®Concealed Sprinklers are marked

with a yellow Stripe or Dot for identification pur-

poses.

Fusible Link Levers: Stainless Steel

UNS-S31600

Seal: Teflon®Tape

Spring: Nickel Alloy

Cover Plate Assembly Materials:

Cover Plate Assembly: Brass

UNS-C26000

Spring: Nickel Alloy

Solder: Eutectic

Cover Finishes:

Bright Brass

Polished Chrome

Painted1White (No. 1004)2

Painted1Ivory (No. 1634)2

Painted1Black (No. 1007) 2

1Painted finish consists of Polyester Baked

Enamel.

2 Sherwin-Williams®Color AnswersInterior

Color Number. Other Colors available on re-

quest. See Sherwin-Williams®Color Answers

Interior Color Selection color numbers.

Ordering Instructions:

To order the Viking Extended Coverage

Horizon®Mirage®Concealed Sprinkler

and Cover Plate Assembly, refer to:

Model B-1 Standard Orifice

Sprinkler Base Part No. 08498 and

Model B-2 Large Orifice

Sprinkler Base Part No. 10485

Cover Plate Assembly

Base Part No. 09804.

Specify sprinkler temperature rating and

finish and temperature rating of

Cover

Plate Assembly.

Accessories:

Concealed Sprinkler Wrenches*

Heavy Duty

PN 08336W/B

Manufactured since 1983

Light Duty**

P/N 10366W/B

* A 1/2" ratchet is required (not available from Vi-

king).

** Ideal for Sprinkler Cabinets.

5. AVAILABILITY AND SERVICE

Viking sprinklers are available through a

network of Domestic, Canadian, and In-

ternational Distributors. See the Yellow

Pagesofthetelephonedirectoryforyour

nearest distributor (listed under “Sprin-

klers Automatic Fire”) or contact The

Viking Corporation.

6. GUARANTEES

For details of warranty, refer to Viking’s

current price schedule or contact Viking

directly.

7. INSTALLATION

WARNING: Viking sprinklers are manu-

factured and tested to meet the rigid

requirements of the approving agency.

The sprinklers are designed to be in-

stalled in accordance with recognized

installation standards. Deviation from

the standards or any alteration to the

sprinkler or cover plate assembly after it

leaves the factory including, but not lim-

itedto,painting,plating,coatingormodi-

fication, may render the sprinkler inop-

erative and will automatically nullify the

approval and any guarantee made by

The Viking Corporation.

A.Sprinklersmustbeinstalledinaccord-

ance with recognized standards in

the country of installation. Regard-

less of the standard used, the instal-

lation must be acceptable to all

Authorities Having Jurisdiction.

B. Sprinklers must be handled with care.

Horizon®Mirage®Concealed Sprin-

klers are protectedwith aplastic pro-

tective shell, which should remain in

place over the sprinkler body during

installation, testing, and any time the

sprinkler is handled or shipped. The

plastic protective shell must be re-

moved prior to placing the system in

service. See paragraph "I" below.

Prior to installation, sprinklers must

be stored in a cool, dry place in their

original shipping container. Never in-

stall sprinklers that have been

dropped, damaged in any way, or

have been exposed to temperatures

in excess of maximum ambient tem-

perature allowed. Such sprinklers

should be destroyed immediately.

C. Extended Coverage Horizon®Mi-

rage®Concealed Sprinklers must be

TECHNICAL DATA

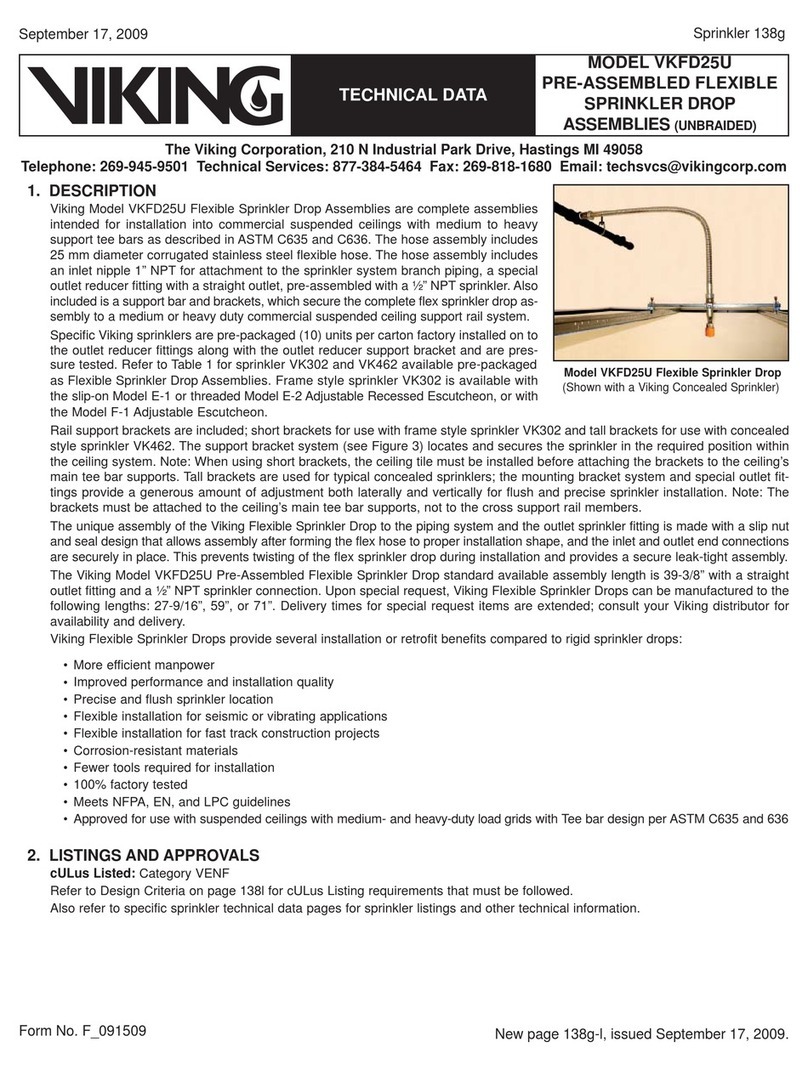

April 13, 1998

Sprinkler 87 b

Extended

Coverage

Concealed

Sprinkler

Protective Cap

Concealed

Sprinkler

wrench**

Part No.

08336W/B

(shown) or

Part No.

10366W/B

** A 1/2" ratchet

is required.

(Not available

through Viking).Figure C

HORIZON® MIRAGE®

EXTENDED COVERAGE

20 Ft X 20 Ft (6.1 M X 6.1 M)

CONCEALED SPRINKLER

Viking Technical Data may be found on

The Viking Corporation’s Web site at :

http://www.vikingcorp.com

The Web site may include a more recent

edition of this Technical Data page.