1. PRODUCT NAME

Viking Microfast®Model M

Residential Horizontal Sidewall

Sprinkler Base Part No. 06769B

2. MANUFACTURER

The Viking Corporation

210 N. Industrial Park Road

Hastings, Michigan 49058, USA

Telephone: (616) 945-9501

(877) 384-5464

Fax: (616) 945-9599

e-mail: techsvcs@vikingcorp.com

3. PRODUCT DESCRIPTION

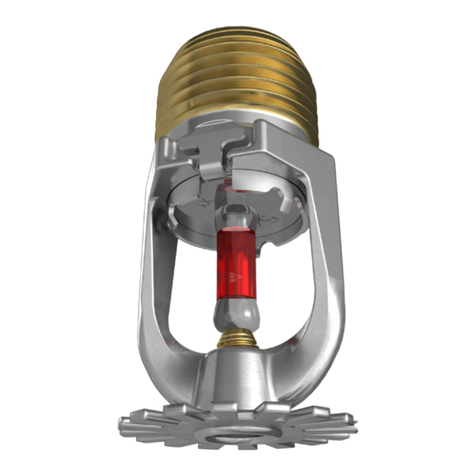

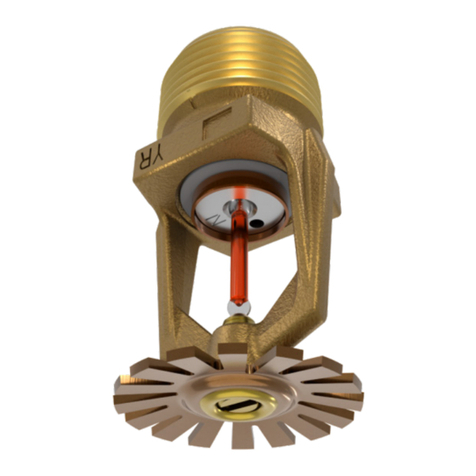

The VikingMicrofast®Model M Residen-

tial Horizontal Sidewall Sprinkler is a

small, high-sensitivity, glass-bulb spray

sprinkler. The sprinkler is available in

several finishes, with temperature rat-

ings to meet design requirements. The

orifice design, with a K-factor of 5.5,

allows efficient use of available water

supplies for the hydraulically designed

fire-protection system.

The small, rugged 3 mm glass bulb and

special deflector combine speed of op-

eration and area of coverage to meet

residential sprinkler standards while be-

ing aesthetically pleasing. During fire

conditions, the heat-sensitive liquid in

the glass bulb expands, causing the

glass to shatter, releasing the pip cap

and sealing spring assembly. The water

flowing through the sprinkler orifice

strikes the sprinkler deflector, forming a

uniform spray pattern to extinguish or

control the fire.

4. TECHNICAL DATA

See approval chart on page 142 c for

approvals.

See chart for minimum water supply re-

quirements and maximum areas of

coverage.

Glass-bulb fluid temperature rated to

-65 °F (-55 °C).

Ratedto175psi(1207kPa)waterwork-

ing pressure.

Factory tested hydrostatically to 500 psi

(3 448 kPa).

Spring: USA Patent No. 4,167,974

Bulb: USA Patent No. 4,796,710

Testing: USA Patent No. 4,831,870

Thread Size: 1/2" (15 mm) NPT

Orifice Size: Nominal 1/2" (15 mm)

K-factor: 5.5 (7,9 metric*)

*See Footnote 7 on approval chart on

page 142 c.

SPRINKLER MATERIALS

Frame - Brass Castings UNS-C84400

Deflector - Copper UNS-C19500

Bulb - Glass, nominal 3 mm diameter

Seal - Teflon®Tape

Spring - Nickel Alloy

Screw - Brass UNS-C36000

Pip Cap - Copper UNS-C14500

ACCESSORIES

Sprinkler Wrenches:

Standard: Part No. 05000CW/B

Recessed: Part No. 07398W

Referto "SPRINKLERACCESSORIES"

for escutcheons.

5. AVAILABILITY AND SERVICE

Viking sprinklers are available through a

network of domestic, Canadian, and in-

ternational distributors. See the Yellow

Pages of the telephone directory for a

localdistributor(listedunder"Sprinklers-

Automatic-Fire") or contact Viking.

Viking Technical Data may be found on

The Viking Corporation’s Web site at

http://www.vikingcorp.com.

The Web site may include a more recent

edition of this Technical Data page.

6. GUARANTEES

For details of warranty, refer to Viking’s

current price schedule or contact The

Viking Corporation directly.

7. INSTALLATION

WARNING: Viking sprinklers are manu-

factured and tested to meet the rigid

requirements of approving agencies.

The sprinklers are designed to be in-

stalled in accordance with recognized

installation standards. Deviation from

the standards or any alteration to the

sprinkler after it leaves the factory in-

cluding, but not limited to: painting, plat-

ing,coating,or modification,mayrender

the sprinkler inoperative, and will auto-

matically nullify the approval and any

guaranteemadebyTheVikingCorpora-

tion.

A. Sprinklers are to be installed in ac-

cordance with the latest published

standardsoftheNationalFireProtec-

tion Association, Factory Mutual,

LossPreventionCouncil,Assemblee

Pleniere, Verband der Sachver-

sicherer or other similar organiza-

tions,andalsowithprovisionsof gov-

ernmental codes, ordinances, and

standards whenever applicable. For

conditionsnotspecificallycoveredby

the Standards, refer to the "Viking

Residential Installation Guide". Final

approval and acceptance of all

residential sprinkler installations

mustbe obtained fromthe Author-

ity Having Jurisdiction. Residential

sprinklers are special-service sprin-

klers for use in one- and two- family

dwellings, mobile homes, and resi-

dential portions of other occupan-

cies, where allowed. The use of resi-

dential horizontal sidewall sprinklers

maybelimitedduetooccupancyand

hazard. The minimum flow rate indi-

cated for a listed area of coverage

must be provided at the sprinkler.

Therefore, the system must be hy-

draulically calculated. Refer to the

Authority Having Jurisdiction prior to

installation.

B. Sprinklers must be handled withcare.

They must be stored in a cool, dry

place in their original container.

Never install sprinklers that have

been dropped or damaged in any

way. Never install any glass-bulb

sprinkler if the bulb is cracked or if

there is a loss of liquid from the bulb.

If a glass bulb lacks the appropriate

amount offluid,it should beset aside

and returned to Viking (or an author-

ized distributor) for analysis as soon

as possible. If the sprinkler is not re-

turned to Viking, it should be de-

stroyed immediately. Never install

sprinklers which have been exposed

to temperatures in excess of maxi-

mum ambient temperature allowed.

Such sprinklers should be destroyed

immediately.

C. Corrosion-resistant sprinklers must

beinstalledwhensubjecttocorrosive

atmospheres. Viking Microfast®

ModelMResidentialHorizontalSide-

wall Sprinklers are not intended for

use in corrosive environments.

D. Use care when locating sprinklers

near fixtures that can generate heat.

Do not install sprinklers where they

Replaces sprinkler page 142 a-c, dated May 14, 1998

(updated approved escutcheons list).

Sprinkler 142 a

January 28, 1999

Form No. F_080588

Units of measure in parentheses may be approximations.

TECHNICAL DATA MICROFAST®MODEL M

RESIDENTIAL HORIZONTAL

SIDEWALL SPRINKLER