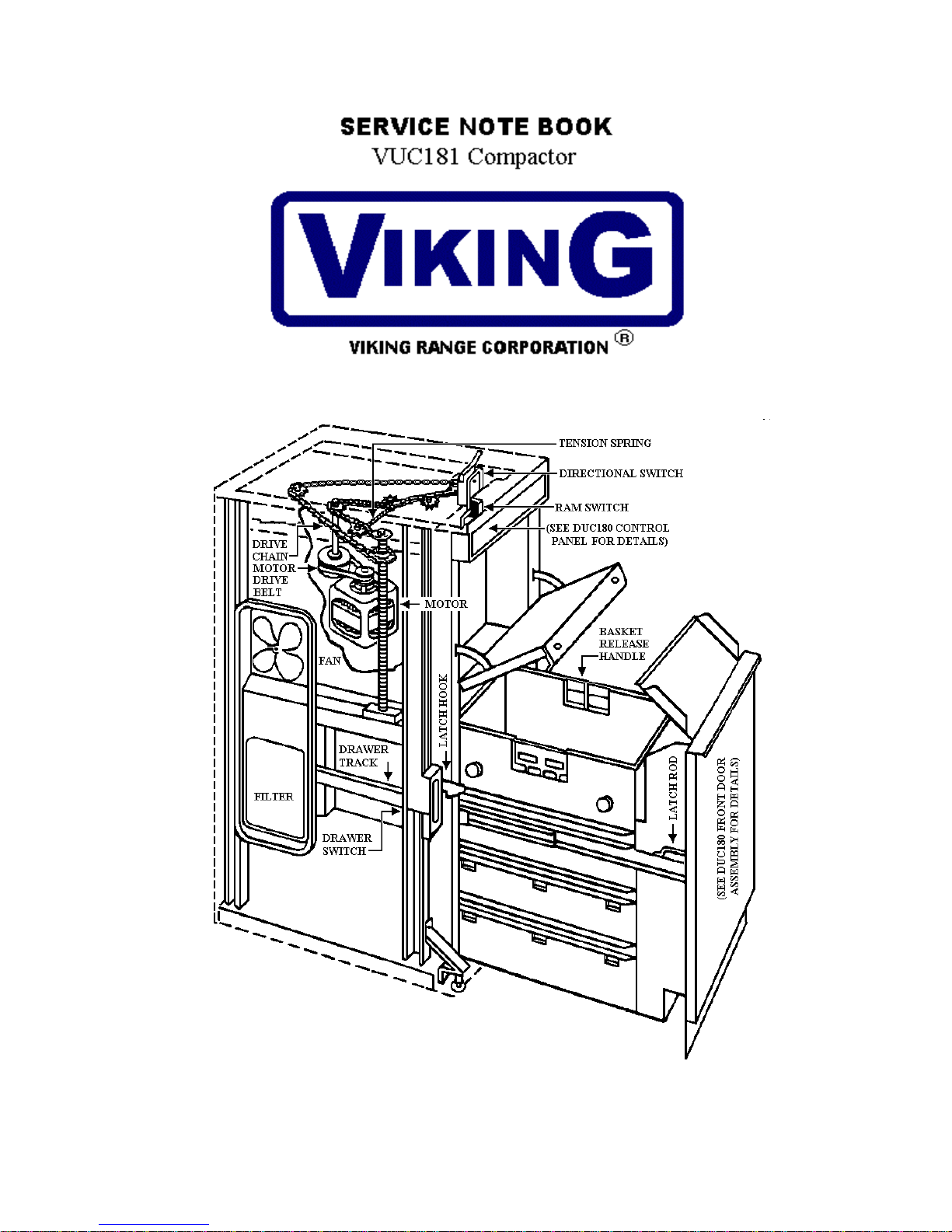

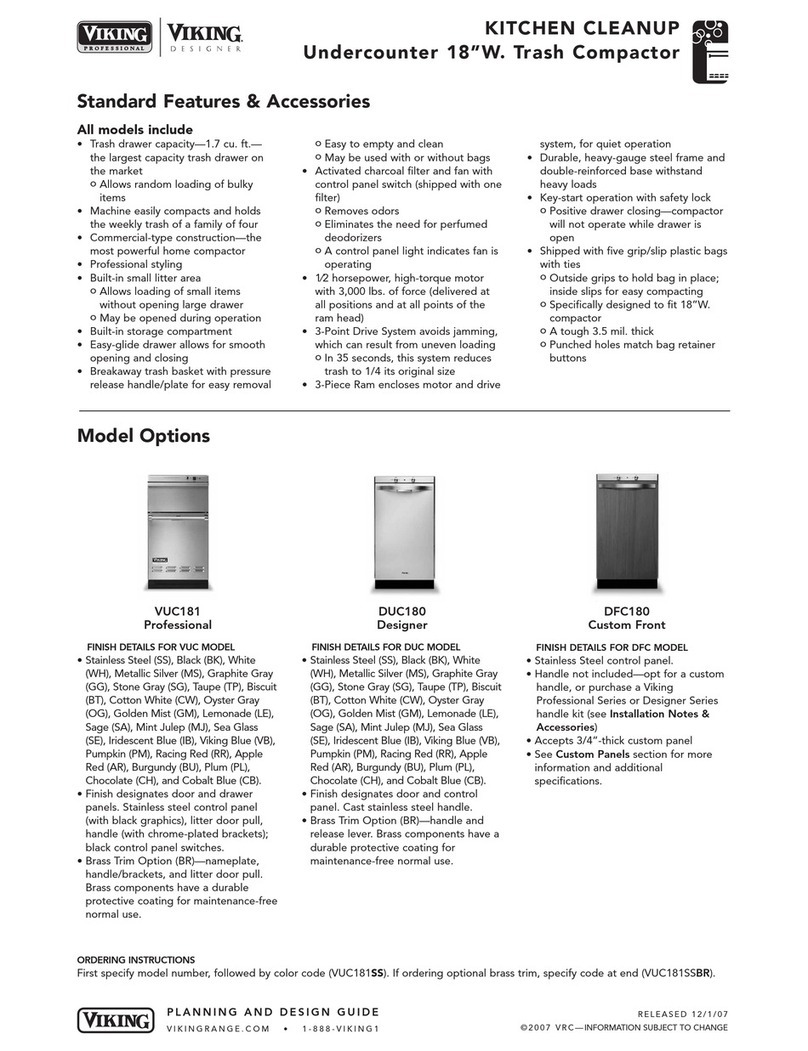

Viking Professional VUC181 Service manual

Other Viking Trash Compactor manuals

Viking

Viking Designer Series User manual

Viking

Viking FCU150 User manual

Viking

Viking Designer DFC180 User manual

Viking

Viking Designer DUC180 User manual

Viking

Viking Professional VUC181 User manual

Viking

Viking Designer DFC180 User manual

Viking

Viking FCU150 User manual

Viking

Viking F1213F User manual

Viking

Viking FCU150 Installation guide

Viking

Viking Professional VUC181 User manual

Popular Trash Compactor manuals by other brands

Whirlpool

Whirlpool GX900QPLQ - 15" Trash Compactor Use and care guide

Vestil

Vestil FM-T-DUMP instruction manual

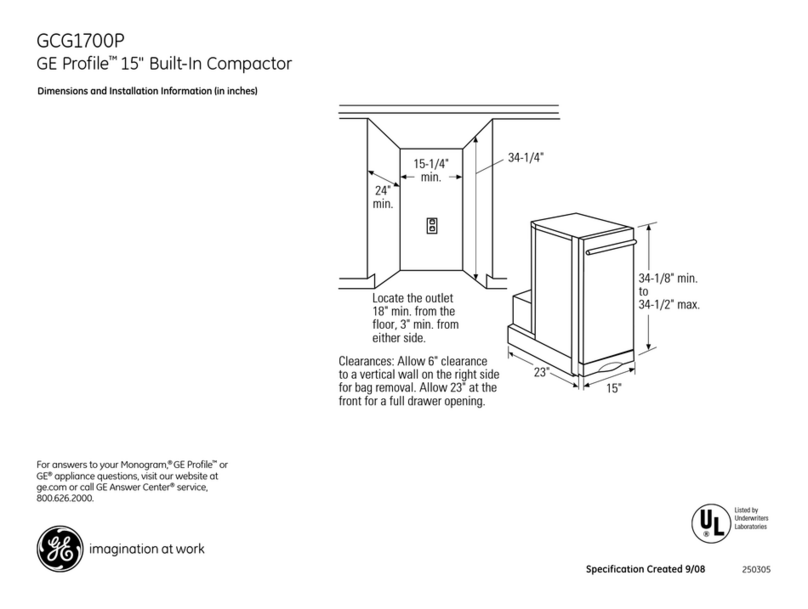

GE

GE GCG1700P Dimensions and installation information

Euro Shatal

Euro Shatal RP4014-50 operating instructions

third coast equipment

third coast equipment SP3410 Operator's manual

Cucine Oggi

Cucine Oggi EKKO CUBE 40 9000 Assembly instructions

GE

GE GCG1700II installation instructions

GE

GE GCG1500RBB Dimensions and installation information

Centro

Centro 85-1066-6 (A01001 Safe use, care and assembly manual

Whirlpool

Whirlpool 9872208 Use and care guide

Jenn-Air

Jenn-Air TC607X2 Use & care guide

Displays2go

Displays2go “THANK YOU” DUAL Assembly instructions