2Table of Contents

Table of contents

Safe Servicing Practices....................................................................3-4

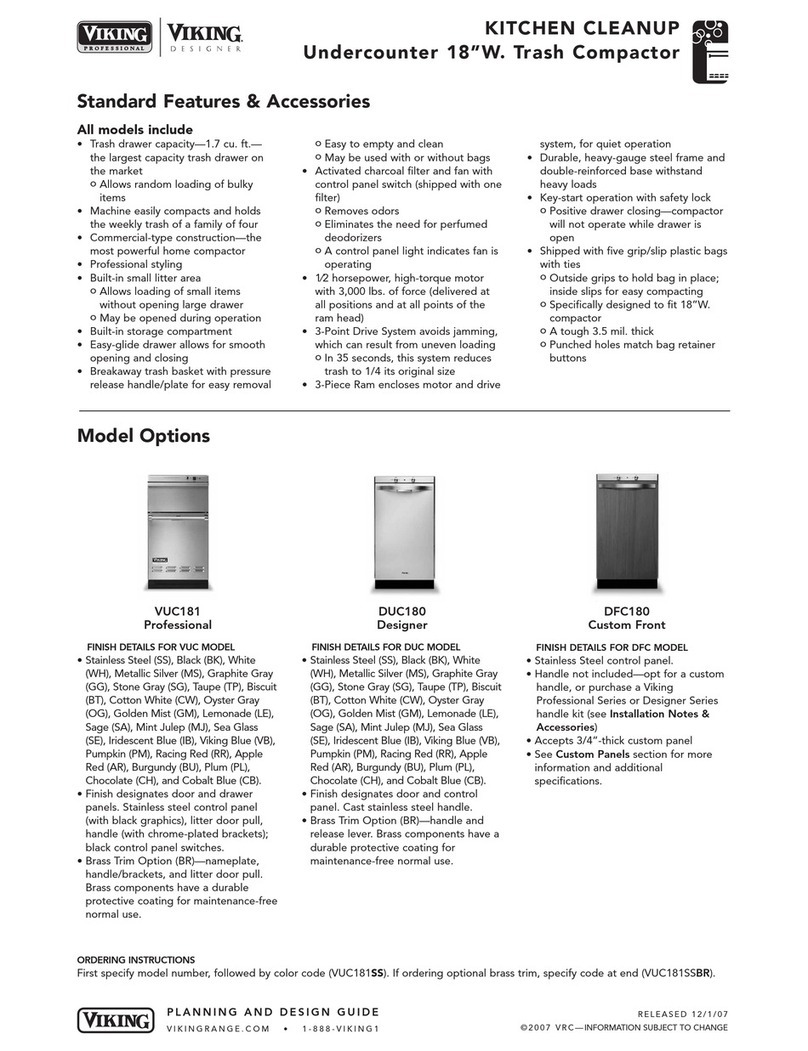

Features .....................................................................................................5

Grounding Instructions........................................................................3

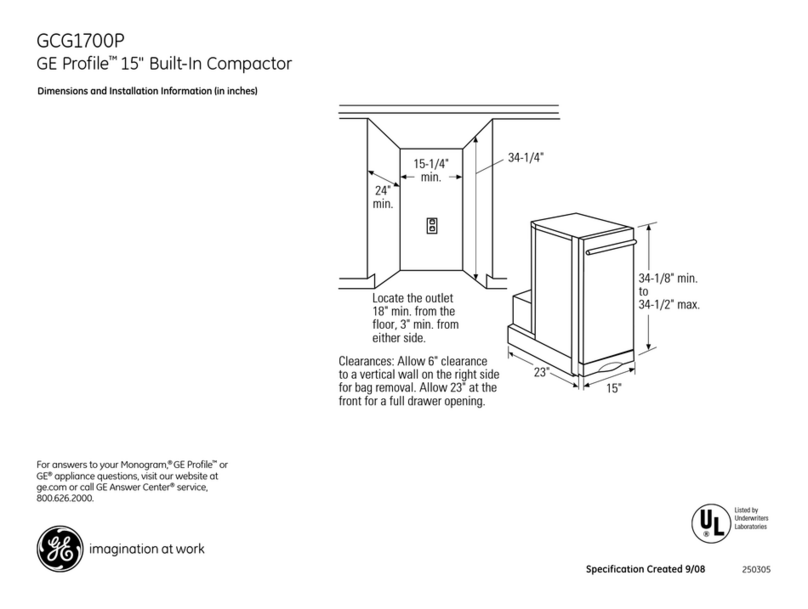

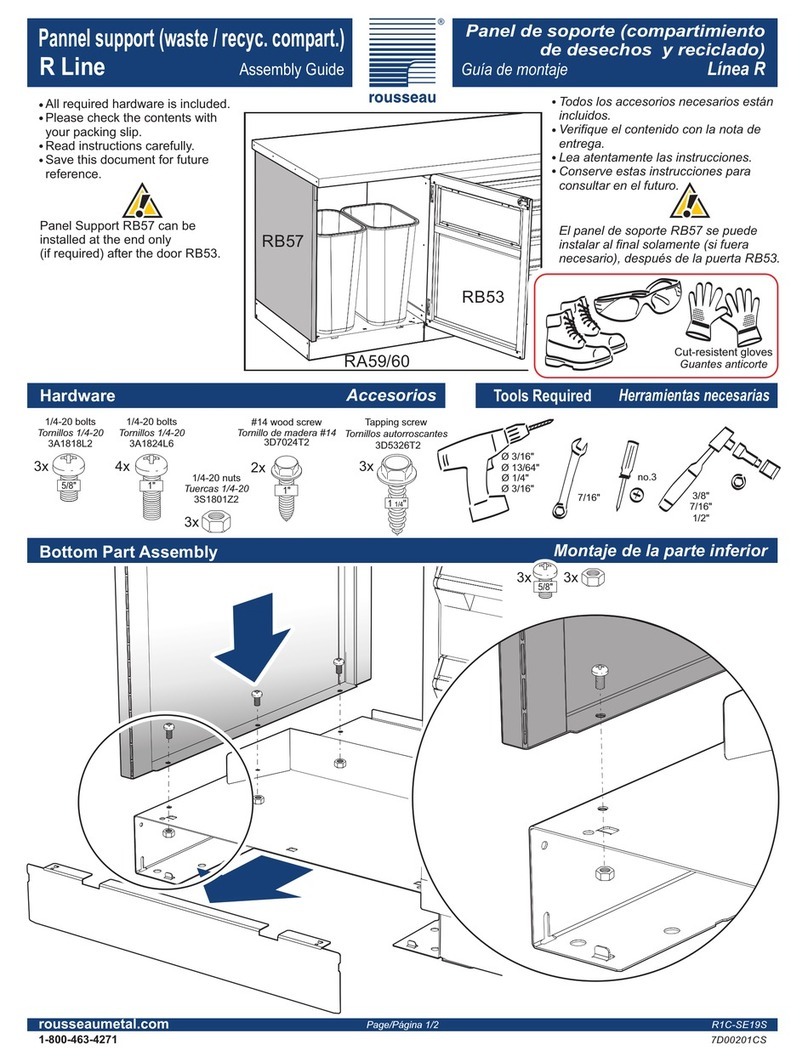

Section A – Installation.........................................................................6

Built-in Installation.................................................................................6

Mounting Straps...............................................................................6

Under-Counter Opening...............................................................6

Cord Clamp ........................................................................................7

Leveling the Compactor ......................................................................7

Section B – Cabinet................................................................................8

Trash Bucket .............................................................................................9

Remove................................................................................................9

Door Strap ................................................................................................9

Remove and Replace......................................................................9

Slide Rails (Cabinet) ............................................................................ 10

Remove and Re-install ................................................................ 10

Slide Rails (Bucket).............................................................................. 10

Remove and Re-install ................................................................ 10

Decorative Door Panel....................................................................... 11

Remove and Re-install ................................................................ 11

Door Pan Assembly............................................................................. 11

Remove and Re-install ................................................................ 11

Door Tab ................................................................................................. 12

Remove and Re-install ................................................................ 12

Safety Interlock Actuator.................................................................. 12

Remove and Re-install ................................................................ 12

Gasket Assembly ................................................................................. 13

Remove and Re-install ................................................................ 13

Trim Cover Assembly.......................................................................... 14

Remove and Re-install ................................................................ 14

Section C – Power Unit Mechanism.............................................. 15

Drive Belt ............................................................................................... 16

Remove and Re-install ................................................................ 16

Main Motor ............................................................................................ 17

Remove and Replace................................................................... 17

Complete Power Unit Mechanism ................................................ 18

Remove and Re-install ................................................................ 18

Drive Wheels ......................................................................................... 18

Remove and Replace................................................................... 18

Ram Screw Assembly......................................................................... 19

Prepare to Remove and Replace ............................................. 19

Compression Plate Assembly.......................................................... 19

Remove and Replace................................................................... 19

Ram Screw Assembly......................................................................... 20

Remove and Replace............................................................. 20,21

Section D – Electrical Components .............................................. 22

Access to Components...................................................................... 23

Remove Cabinet Cover ......................................................... 23,24

Re-install Cabinet Cover ............................................................. 25

Control Panel Assembly .................................................................... 25

Remove and Re-install ................................................................ 25

Display Module Assembly................................................................ 26

Remove and Re-install ................................................................ 26

Power Supply Board........................................................................... 27

Remove and Re-install ................................................................ 27

Control Board........................................................................................ 28

Remove and Re-install ................................................................ 28

Key Switch.............................................................................................. 28

Remove and Replace................................................................... 28

Interlock Switch Assembly............................................................... 29

Remove and Re-install ................................................................ 29

Upper Limit Switch Assembly......................................................... 29

Remove and Replace................................................................... 29

Lower Limit Switch.............................................................................. 30

Remove and Replace................................................................... 30

Motor Centrifugal Switch Assembly............................................. 30

Remove and Replace................................................................... 30

Motor Capacitor................................................................................... 31

Test, Remove and Replace ......................................................... 31

Odor Disk Gear Motor ....................................................................... 32

Remove and Replace................................................................... 32

Power Cable........................................................................................... 33

Remove and Replace................................................................... 33

Section E – Troubleshooting

Troubleshooting Table....................................................................... 34

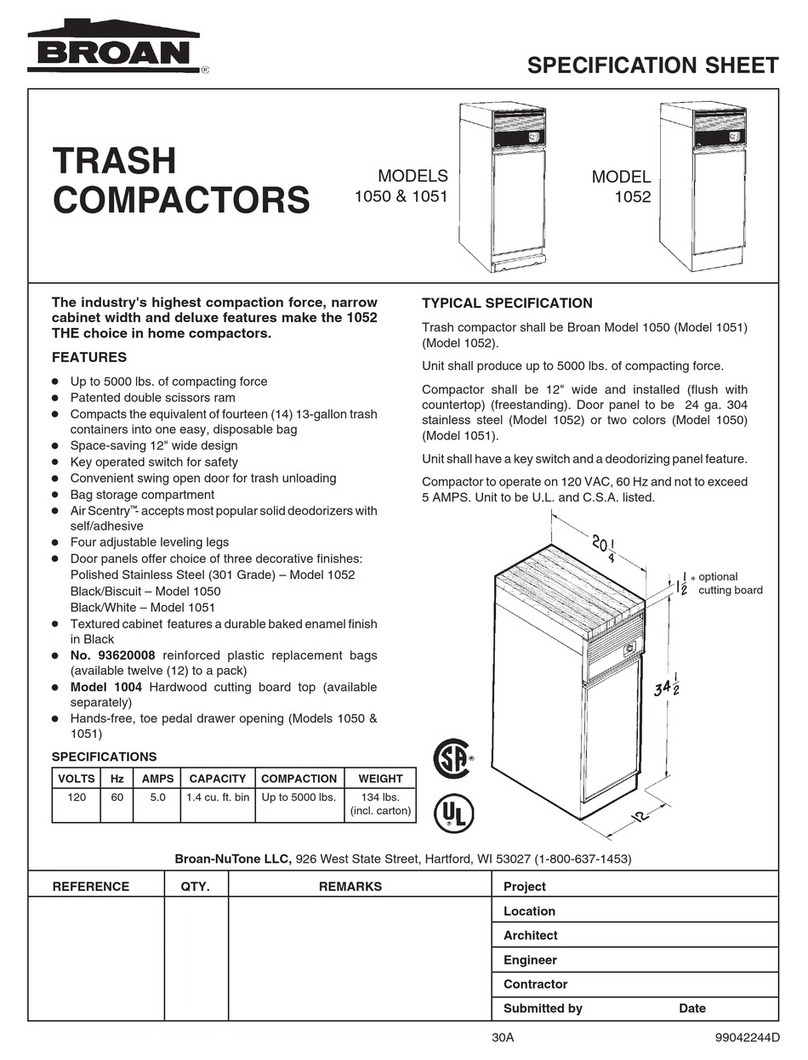

Section F – Specications

Specications Table ............................................................................ 37

Section G – Diagrams and Parts List

Wiring Schematic ................................................................................ 38