2/48 NT00000603-JBRB-ECOWATT-PR-AN-191202

CONTENTS

1. GENERAL INFORMATION ................................................................................................................ 3

1.1 Warnings .................................................................................................................................. 3

1.2 Safety instructions ................................................................................................................... 3

1.3 Reception - Storage.................................................................................................................. 3

1.4 Warranty .................................................................................................................................. 4

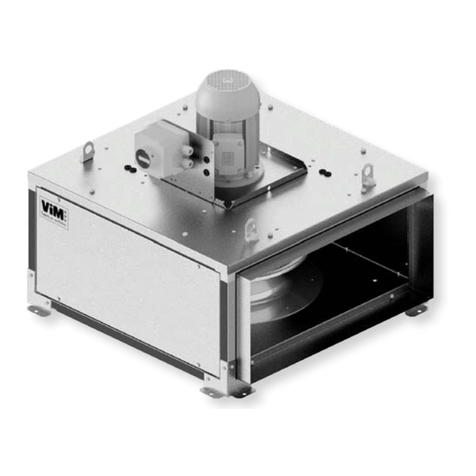

2. PRODUCT PRESENTATION.............................................................................................................. 4

2.1 Description................................................................................................................................ 4

2.2 Aeraulic curves ........................................................................................................................ 7

3. INSTALLATION .................................................................................................................................. 9

3.1 Dimensions and weight ............................................................................................................ 9

3.2 Handling ................................................................................................................................. 13

3.3 Choice of location................................................................................................................... 14

3.4 Ceiling-mounted installation ................................................................................................... 14

3.5 Accessories assembly............................................................................................................ 15

4. AERAULIC CONNECTION .............................................................................................................. 15

5. ELECTRICAL CONNECTION.......................................................................................................... 16

5.1 Prior precautions .................................................................................................................... 16

5.2 Electrical features .................................................................................................................. 16

5.3 Electrical connection of the local on-o switch ....................................................................... 16

5.4 Electrical connection of an external On / O control .............................................................. 17

5.5 Relay electrical connection - ventilation fault.......................................................................... 18

5.6 Electrical connection of optional TCOM remote control ......................................................... 19

5.7 Electrical connection of a 2V BCCA....................................................................................... 21

5.8 Electrical connection of a sensor (optional accessory)........................................................... 22

5.9 Electrical connection of a potentiometer (optional accessory) ............................................... 23

5.10 Electrical connection of a CENE power meter (optional accessory) ...................................... 24

6. COMMISSIONING............................................................................................................................ 24

6.1 Description of RMEC controller keys...................................................................................... 24

6.2 Calibration of built-in pressure sensors (COMPULSORY STEP)........................................... 24

6.3 Access levels.......................................................................................................................... 25

6.4 Setting of date and time.......................................................................................................... 26

6.5 Checking of active operating mode........................................................................................ 26

6.6 Local On/O control (factory setting)...................................................................................... 27

6.7 Selection of the main operating mode.................................................................................... 27

6.8 COP: Constant pressure ........................................................................................................ 28

6.9 CAV: Constant airow – 1 setting ........................................................................................... 28

6.10 CAV: Constant airow – 2 settings ......................................................................................... 29

6.11 VAV: Sensor-type analogue input airow control.................................................................... 30

6.12 VAV : Potentiometer-type analogue input airow control........................................................ 34

6.13 Clock function......................................................................................................................... 36

6.14 Power meter conguration...................................................................................................... 39

6.15 List of faults reported by the R1 contact output in ALARM function ...................................... 40

7. MENU AND MODBUS SETTINGS................................................................................................... 40

7.1 Modbus conguration ............................................................................................................. 40

7.2 Main settings / register tables................................................................................................. 42

8. MAINTENANCE ............................................................................................................................... 43

8.1 Prior precautions .................................................................................................................... 43

8.2 Maintenance frequency.......................................................................................................... 43

8.3 Access to electric fan.............................................................................................................. 43

8.4 Electric fan replacement......................................................................................................... 44

8.5 Spare parts............................................................................................................................. 46

9. WASTE MANAGEMENT.................................................................................................................. 46

9.1 Treatment of packaging and general industrial waste (GIW) ................................................. 46

9.2 Treatment of Professional WEEE........................................................................................... 46