2/60 NT00000658-TEDH-V-F400-ECOWATT-AN-210609

SUMMARY

1. GENERAL........................................................................................................................................... 3

1.1 Disclaimers............................................................................................................................... 3

1.2 Safety instructions.................................................................................................................... 3

1.3 Acceptance – Storage.............................................................................................................. 3

1.4 Warranty................................................................................................................................... 4

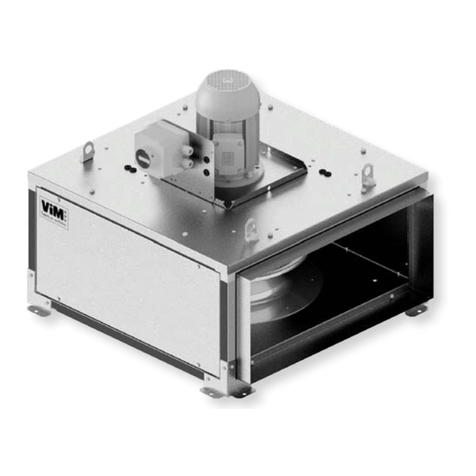

2. PRODUCT PRESENTATION.............................................................................................................. 4

3. INSTALLATION .................................................................................................................................. 5

3.1 Dimensions and weights........................................................................................................... 5

3.2 Handling ................................................................................................................................... 6

3.3 Summary charts of assembly and accessories........................................................................ 7

3.4 Removing the caps................................................................................................................. 13

3.5 Mounting the roof fan.............................................................................................................. 13

3.6 Mountingtherooffandeectors............................................................................................. 14

4. ELECTRICAL CONNECTION.......................................................................................................... 15

4.1 Preliminary precautions.......................................................................................................... 15

4.2 Electrical characteristics......................................................................................................... 16

4.3 Wiring of INTZ safety switch................................................................................................... 17

5. COMMISSIONING AND CONFIGURATION OF ONE-PHASE CONTROLLERS

SIZES 355/400/450........................................................................................................................... 19

5.1 Presentation of the VENTIDRIVE single-phase controller...................................................... 19

5.2 Modbus connection - Connection to a BMS........................................................................... 21

5.3 Supported Modbus commands............................................................................................... 22

5.4 Relay operation ...................................................................................................................... 29

5.5 Smoke extraction operation.................................................................................................... 30

5.6 VAVvariableairowmode...................................................................................................... 31

5.7 CAVconstantairowmode .................................................................................................... 40

5.8 COP constant pressure mode................................................................................................ 41

6. COMMISSIONING AND CONFIGURATION OF THREE-PHASES CONTROLLERS

SIZES 500/630/710........................................................................................................................... 43

6.1 Presentation of the INVENTO three-phases controller........................................................... 43

6.2 Modbus connection - Connection to a BMS........................................................................... 45

6.3 Relay operation ...................................................................................................................... 48

6.4 Smoke extraction operation.................................................................................................... 48

6.5 VAVvariableairowmode...................................................................................................... 49

6.6 CAVconstantairowmode .................................................................................................... 51

6.7 COP constant pressure mode................................................................................................ 54

7. MAINTENANCE................................................................................................................................ 57

7.1 Maintenance frequency.......................................................................................................... 57

7.2 Spare parts............................................................................................................................. 58

8. WASTE MANAGEMENT.................................................................................................................. 59

8.1 Treatment of Packagings and non dangerous wastes ........................................................... 59

8.2 Treatment of a Professional WEEE........................................................................................ 59