3/16 NT00000439-KDTA-F400-KDTR-F400-AN-210121

1. GENERAL POINTS

1.1 Warnings

This product has been manufactured according to rigorous technical rules of safety in conformity with EC

standards. The EC declaration may be downloaded from the Internet site (address given on the last page).

Before installing and using this product, carefully read these instructions, which contain important indica-

tions for your safety and the user’s safety during the installation, commissioning and maintenance of

this product. Once the installation is terminated, keep this manual handy nearby the machine for future

consultation.

This product must be installed (installation, connections, commissioning, maintenance) and all other inter-

ventions performed by a professional applying recognized good practice procedures, and respecting the

standards and safety regulations in force. The installation must be made in accordance with the prescrip-

tions indicated in the Electromagnetic Compatibility (EMC) and Low Voltage (LV) Directives.

We advise all people exposed to risks to scrupulously respect the accident prevention standards. The ma-

nufacturer may not be held liable for any human injury and/or material damage resulting from the non-res-

pect of the safety instructions or from a change made on the product.

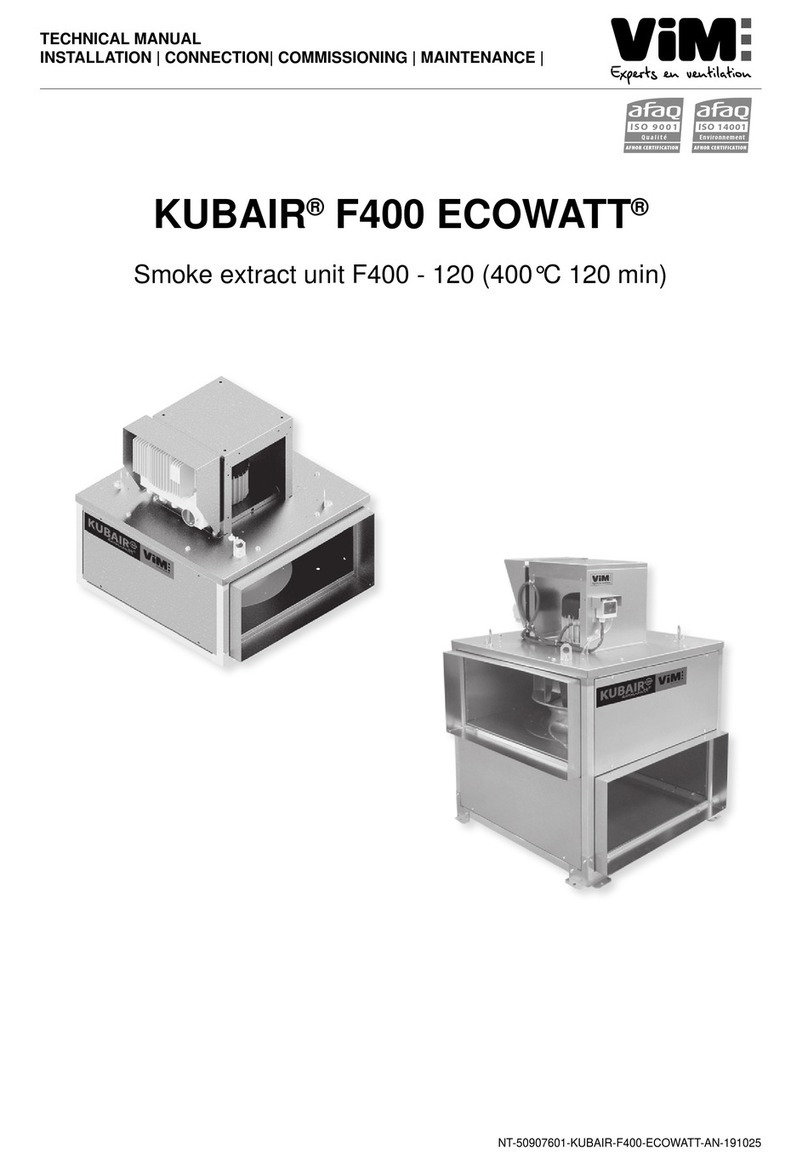

The KDTAF400 and KDTR F400 smoke extracting units are designed for smoke extraction and ventilation

applications in residential buildings, commercial buildings, industrial and logistics buildings and covered

car paks :

• Interior or exterior installation

• Ambient temperature: -20°C / +50°C

• Relative humidity: max. of 95% without any condensation

• Non-potentially explosive atmosphere

• Atmosphere with low salinity, without any corrosive chemical agents.

1.2 Safety instructions

• Wear suitable PPE (Personal Protective Equipment) before any intervention.

• Before installing the extraction fan unit and its accessories, make sure that the support and the loca-

tion are suciently resistant to withstand the complete unit's weight.

• Do not open the access panels before the power is cut at the lockable safety switch present on the

unit.

• If any work is to be performed on the device, cut o the power supply at the main circuit-breaker and

make sure that no one is able to turn it back on accidentally.

• Make sure that moving parts are stopped.

• Make sure that the impeller is not accessible from connection tappings (connection duct or mesh

protection)

• If the suction or discharge holes of the unit are not connected, use an appropriate guard AVRZ,

PPHZ or APC.

Before starting, check the following points:

• Make sure that the device does not contain any foreign body.

• Make sure that all the components are attached to their original locations.

• Check manually that the impeller does not rub or is not blocked.

• Make sure that the ground connection is connected.

• Make sure the access panel is well locked.