4/48 NT-50905701-TEDH-TEDV-F400-ECOWATT-AN-191025

ENGLISH

1 . 3 A c c e p t a n c e – St o r a g e

In case of missing items or delivery of non conforming, partially or totally damaged products, the Buyer

shall make, in accordance with article 133-3 of the French Commercial Code, reservations in writing on the

transporterreceiptandconrmthemwithinseventy-two(72)hoursbyregisteredletteralongwithacopy

addressed to the seller. Should the Buyer fail to make reservations when he receives the equipment, he

will not be allowed to make any future claim against us.

The product must be stored protected from the weather, shocks and dirt due to splashings or splatterings

of any kind during transport from the supplier to the end customer, and onto the worksite before installation.

1 . 4 W a r r a n t y

The equipment is warranted for twelve (12) months – Parts only – from date of manufacture.

VIM agrees to replace parts or the equipment whose operation is recognised defective by our departments,

excluding all damages or penalties, such as operating losses, commercial prejudice, or other intangible or

indirect losses.

Our warranty does not cover: (1) defects resulting from an abnormal use or an use not conforming to the

recommendations indicated in our manuals; (2) defects observed following normal wear; (3) incidents

caused by negligence, lack of monitoring or maintenance; (4) defects due to the inappropriate installation

of the devices or unsuitable pre-installation storage conditions.

In any case, VIM may not be held liable for transformed or repaired equipment even partially.

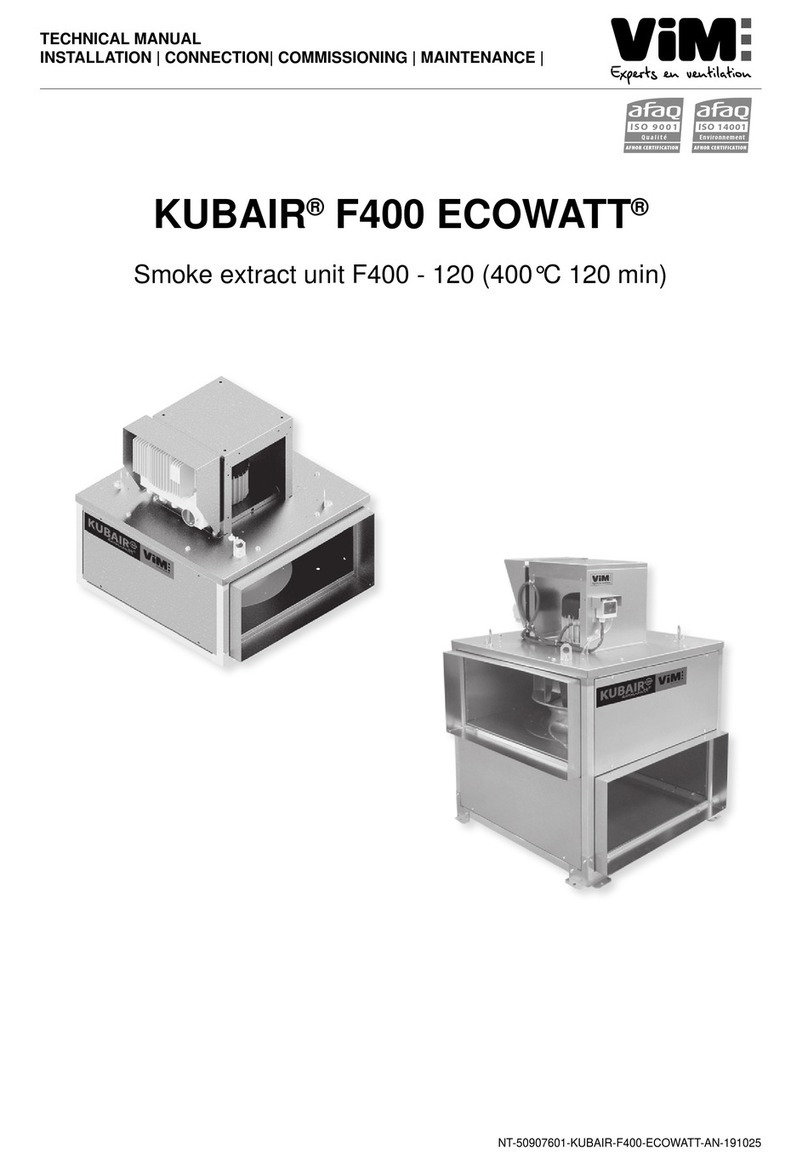

2 . P R O D U C T P R ESENT A T IO N

ECCerticateF400-120No.1812-CPR-1085,accordingtoEuropeanStandardNFEN12101-3

Approved F400 120 (400°C 120min).

• TEDH F400 ECOWATT®: horizontal discharge through 2 or 3 sides.

• TEDV F400 ECOWATT® : vertical discharge through 2 or 3 sides.

• 6 sizes : 355 / 400 / 450 / 500 / 630 / 710.

• Flowrates from 200 to 24 000 m3/h according to model.

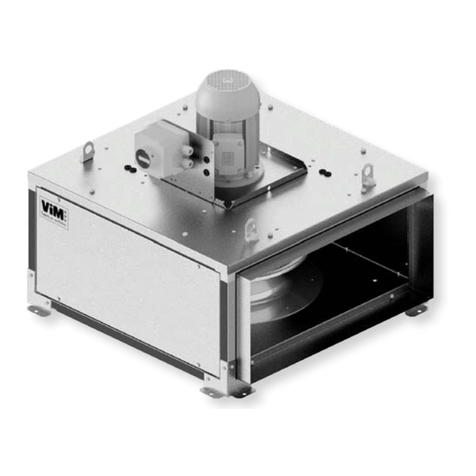

C o n s t r u c t i o n :

• Galvanized steel high performance backward fan.

• Convergent/divergent inlet cones for airflow optimization, higher efficiency and reduced sound level.

• Direct coupling on fan shaft

• Galvanized steel plate, frame and motor support

• 4 lifting lugs according to model.

• 4 lifting slings.

• RAL 7024 grey lacquered support covers:

• Easy dismantling to access roof fan fixing points.

• Mesh protection made of galvanised steel sheet metal, pre-lacquered grey RAL 7024.

• Meshes according to NF EN ISO 12499 standard.

• Arm caps and mesh protection made of sheet metal, pre-lacquered grey RAL 7024.

• Cover cap made of ABS PMMA, pre-lacquered grey RAL 7024.

• Vertical discharge version : addition of 4 RAL 7024 lacquered steel air deflectors factory fitted, (TEDV F400

ECOWATT®model) or available as a kit for assembling on site (KRVT).

• ECOWATT®motor, F class, 3 phases with remote IP55 controller :

-Input controller 1 phase 230V 50/60Hz for 355 up to 450 sizes (Compacto 08 or 11).

-Input controller 3 phases 400V 50/60Hz for 500 up to 710 sizes (Invento S 15,30 or 55).

-Thermal protection fitted in controller.