Vimar RS16.P User guide

Installer manual

RS16.P

24 Vdc control unit for sliding gate ACTO 404D

2

RS16.P

EN

Contents: Page

1 - Product characteristics................................................................................................................................................................................................ 1

2 - Example of installation................................................................................................................................................................................................ 1

3 - Description of the terminal blocks............................................................................................................................................................................... 2

4 - Connecting accessories.............................................................................................................................................................................................. 3

5 - Changing the programmable parameters ................................................................................................................................................................... 5

6 - Trimmer functions ....................................................................................................................................................................................................... 6

7 - Functions of the buttons ............................................................................................................................................................................................. 6

8 - DIP-switch functions ................................................................................................................................................................................................... 6

9 - LED functions.............................................................................................................................................................................................................. 7

10 -

Remote control programming ..................................................................................................................................................................................... 7

1

RS16.P

EN

1 Product characteristics

Control unit for governing sliding gear motors at 24 Vdc with a maximum power of 80 W for gates of maximum length 6 m and 400 kg in weight,

equipped with integrated magnetic limit switches on the board, encoder (used for obstacle detection) integrated receiver at 433 MHz and integrated

battery charger.

The control unit enables:

- customizing the space and speed of deceleration

- equipped with obstacle detection system

-LED for input diagnostics

- integrated receiver with capacity for 50 remote controls (hard coded or rolling code)

- current control for electric motor protection

Tecnichal characteristics

Supply 120 ÷ 230 Vac

Motor power supply 24 Vdc

Maximum motor power 80 W

Output for flashing light 24 Vdc 10 W max

Accessories power supply 24 Vdc 300 mA

Receiver memory 50 remote controls

Receiver frequency 433 MHz

Remote controls code Rolling code or fixed

Fuse F1 (line protection) 5x20 mm T1.6 A

Operating temperature -10 ÷ +50°C

2 Example of installation

Components for creating a complete system with ESM7 or EK14 kit

Main Components Accessories (optional)

Description Article Ref. Qty Components in kit EK14 Description Article Ref. Qty

Operator ESM7 A 1 YES Key switch EDS1 F 1

Flashing light ELA5 B 1 YES Post-mounted photocells EFA3 G 1

Remote control ETR5 C 1 YES Posts EE21 H 2

Wall-mount photocells EFA3 D 1 YES Pack of 2 batteries 12 V 1.3 Ah

and wiring harness ZBA7 1

Rack ZE03/1 E4 (4 m) NO

A

C

B

D

E

F

4x0.5 mm²

2x0.5 mm²

D

G

H

G

H

2x1 mm²

3x0.5 mm²

4x0.5 mm² 2x0.5 mm²

3x1.5 mm² (230 Vac)

2

RS16.P

EN

PED

P. P.

PHC

PH

STOP

COM

ON

12345678

N

N

F

-

+

L

SW1 SW2

PHC PHO STP MRX

PWR

51

PRGMRX

+B

-B

-B +B

ANT _

ANT _

MOTORENCODER

51 52 62 63 61 99

17 011 1

0

SCA

-

PHC PHO STP

51 52 62 63 61 99

17 011 1

0

24V-

24V+

24V-

BLINK+

SCA+

C

N

N

F

L

L

N

230 Vac

120 Vac

-+

-+

12 Vdc

1,3Ah

12 Vdc

1,3Ah

+B

-B

-B +B

R

78

ANT _

ANT _

M

F1 (5x20) T 1.6A

B

B

A

A

C

D

D

3 Description of the terminal blocks

PED

P. P.

PHC

PH

STOP

COM

ON

12345678

N

N

F

-

+

L

SW1 SW2

PHC PHO STP MRX

PWR

51

PRGMRX

+B

-B

-B +B

ANT _

ANT _

MOTORENCODER

51 52 62 63 61 99

17 011 1

0

SCA

-

PHC PHO STP

51 52 62 63 61 99

17 011 1

0

24V-

24V+

24V-

BLINK+

SCA+

C

N

N

F

L

L

N

230 Vac

120 Vac

-+

-+

12 Vdc

1,3Ah

12 Vdc

1,3Ah

+B

-B

-B +B

R

78

ANT _

ANT _

M

F1 (5x20) T 1.6A

B

B

A

A

C

D

D

PED

P. P.

PHC

PH

STOP

COM

ON

12345678

N

N

F

-

+

L

SW1 SW2

PHC PHO STP MRX

PWR

51

PRGMRX

+B

-B

-B +B

ANT _

ANT _

MOTORENCODER

51 52 62 63 61 99

17 011 1

0

SCA

-

PHC PHO STP

51 52 62 63 61 99

17 011 1

0

24V-

24V+

24V-

BLINK+

SCA+

C

N

N

F

L

L

N

230 Vac

120 Vac

-+

-+

12 Vdc

1,3Ah

12 Vdc

1,3Ah

+B

-B

-B +B

R

78

ANT _

ANT _

M

F1 (5x20) T 1.6A

B

B

A

A

C

D

D

PED

P. P.

PHC

PH

STOP

COM

ON

12345678

N

N

F

-

+

L

SW1 SW2

PHC PHO STP MRX

PWR

51

PRGMRX

+B

-B

-B +B

ANT _

ANT _

MOTORENCODER

51 52 62 63 61 99

17 011 1

0

SCA

-

PHC PHO STP

51 52 62 63 61 99

17 011 1

0

24V-

24V+

24V-

BLINK+

SCA+

C

N

N

F

L

L

N

230 Vac

120 Vac

-+

-+

12 Vdc

1,3Ah

12 Vdc

1,3Ah

+B

-B

-B +B

R

78

ANT _

ANT _

M

F1 (5x20) T 1.6A

B

B

A

A

C

D

D

PED

P. P.

PHC

PH

STOP

COM

ON

12345678

N

N

F

-

+

L

SW1 SW2

PHC PHO STP MRX

PWR

51

PRGMRX

+B

-B

-B +B

ANT _

ANT _

MOTORENCODER

51 52 62 63 61 99

17 011 1

0

SCA

-

PHC PHO STP

51 52 62 63 61 99

17 011 1

0

24V-

24V+

24V-

BLINK+

SCA+

C

N

N

F

L

L

N

230 Vac

120 Vac

-+

-+

12 Vdc

1,3Ah

12 Vdc

1,3Ah

+B

-B

-B +B

R

78

ANT _

ANT _

M

F1 (5x20) T 1.6A

B

B

A

A

C

D

D

Terminal Description Rated data

NNeutral

120÷230 Vac

Earth

LPhase

17 Photo-test or gate open

warning light positive 24 Vdc 120 mA

0Accessories negative

11 Flashing light positive 24 Vdc 10 W

0Accessories negative

1Accessories positive 24 Vdc 300 mA

0Accessories negative

51 Step by step (N.O.)

52 Pedestrian (N.O.)

62 Photocell when closing

(N.C.)

63 Photocell (N.C.)

61 Stop (N.C.)

99 Common inputs

-B Emergency battery negative

+B Emergency battery positive

ANT Aerial signal

-Aerial earth

3

RS16.P

EN

3.1 Description of output function

0-1 Accessories power supply:

Permanent 24 V DC output.

0-11 Blinking:

24 Vdc output powered when the gate is moving.

0-17 Photo-test or gate open warning light:

24 V DC output for signalling gate status or performing the safety test:

With DIP 8 = OFF it is Gate Open Warning Light

- Not powered with gate closed

- Powered continuously with gate open or moving

With DIP 8 = ON it is Photo-test

Used for the power supply of the transmitters of the safety devices.

Note:

Using the photo-test requires specic wiring of the safety devices (par. 4.3).

3.2 Description of input function

51 Step by step (N.O.):

Sequential command input, to control the complete travel of the gate. It works with the following cycle: open-stop-close-stop or open-stop-

close-open according to the setting of DIP 3

52 Pedestrian (N.O.):

Command input for opening to the pedestrian distance.

61 Stop (N.C.):

Gate stops, does not turn o automatic closing.

If not used, jumper with the common (99)

62 Photocell when closing - PHC (N.C.):

Photocell when closing, with the gate stationary it allows opening, when opening it does not trigger, with the gate open it does not allow

closing and on release it resets the automatic closing time, when closing it commands immediate reopening.

If not used, jumper with the common (99)

63 Photocell - PH (N.C.):

Functions according to the DIP 6 setting.

DIP 6 = OFF: photocell, active both when closing and when opening, with the gate stationary it does not allow opening, during opening it

stops the movement and on release it continues opening, with the gate open it does not allow closing and on release it resets the automatic

closing time, when closing it stops the movement and on release it commands reopening.

DIP 6 = ON: safety sensitive edge, N.C. dry contact, with the gate stationary it does not allow opening, when opening it disengages, with

the gate open it does not allow closing and on release it resets the automatic closing time, when closing it disengages.

If not used, jumper with the common (99).

4 Connecting accessories

4.1 Key switch and control devices

EDS1

Step by step

Pedestrian

COM COM

N.O. N.O.

N.C. N.C.

996163625251

PED

COM

P. P.

COM

N.O.

COM

N.O.

N.C. N.C.

52 51 62 9963 64 61

PED

COM

P.P.

4

RS16.P

EN

-

+

24V-

24V+

-

+

NO

-

+

COMNC

(FSW)

NO

-

+

COMNC

(FSW)

PHC

PH

COM

RX1 RX2TX1 TX2

-

PHC PHO STP

51 52 62 63 61 99

17 011 1

0

4.2 Photocells and photocells when closing

Normally closed contact (when the photocells are not engaged the PHC LED must be on), if not used then jumper between COM. and PHC, you must

observe the polarity of the power supply for the photocells:

4.3 Photocells and photocells when closing with photo-test active (DIP 8 = ON)

-

+

24V-

24V+

-

+

NO

-

+

COMNC

(FSW)

NO

-

+

COMNC

(FSW)

PHC

PH

COM

RX1 RX2TX1 TX2

-

PHC PHO STP

51 52 62 63 61 99

17 011 1

0

SCA+

ON

12345678

AN

5

RS16.P

EN

4.4 Sensitive edge

51 52 9962 63 61

BAR

COM

4.5 Stop push button

52 51 62 9963 64 61

STOP

COM

5 Changing the programmable parameters

APERTURA

APERTURA

The control panel is programmed by default with the following parameters:

- automatic closing: 30 s

- opening direction: to the right

- pedestrian opening position: 1 m

Notes:

Do not change the wiring for the electric motors. To reverse the opening direction, follow the procedure described below in paragraph 5.2.

The control panel never needs travel setting as this is automatically measured with each action. When the card is started a full open-close action is per-

formed to calibrate the travel (it takes place at slower speed as the control panel does not know the exact position of the gate).

To change the default settings, follow the instructions provided below.

NOTES: to change the programmable parameters, the gate must be stationary.

WARNING! THE SAFETY DEVICES ARE DISABLED WHILE THE PROGRAMMABLE PARAMETERS ARE BEING CHANGED.

5.1 Changing the automatic closing time

1. While the gate is stationary, press and hold PRG for 2 s; the ashing light comes on and remains steadily lit to indicate that programming is in progress.

The gate closes and reopens.

2. When the gate reaches its opening stop limit, once the desired reclosing time has elapsed (120 s max), press 51 (the gate closes again).

OPENING

6

RS16.P

EN

Trimmer Description

MOT 1 Power of motor (turn the trimmer clockwise to increase the power)

7 Functions of the buttons

Button Description

PRG Button for programming the travel

MRX Button for programming or deleting remote controls

51 Step-by-step command button

5.2 Reversing the opening direction

1. While the gate is stationary and not closed, press and hold PRG for 2 s; the ashing light comes on and remains steadily lit to indicate that program-

ming is in progress. The gate closes.

2. Press MRX (the gate stops).

3. Create a pulse (e.g. Press 51); the gate begins to close.

5.3 Changing the pedestrian opening position

1. Have a remote control available with the 2nd radio channel stored.

2. While the gate is closed, press and hold PRG for 2 s; the ashing light comes on and remains steadily lit to indicate that programming is in progress.

The gate opens.

3. Once the desired opening position has been reached, press the button on the remote control stored as the 2nd radio channel.

Note:

If you want to return the control panel to default, perform the following procedure:

1. Disconnect the power to the control panel.

2. Press and hold the PRG button.

3. Reconnect the power to the control panel and wait for the ashing light to come on steady.

4. After 3 sec., release the PRG button. The ashing light will turn o.

5. The control panel is now set with the default times.

6 Trimmer functions

O

1

-

+

P

HC PHO STP MRX

PWR

51

6

361 99

O

1

-

+

P

H

C

P

H

O

S

TP

MRX

PWR

5

1

63

61

99

-

+

TP

9

ON

12345678

+

MR

X

PWR

51

PRGMRX

A

N

A

N

O

N

1

2

3

4

5

6

7

8

+

MRX

PWR

5

1

P

R

G

MRX

AN

AN

ON

1234567

+

PWR

51

PRGMRX

8 DIP-switch functions

ON

12345678

PWR

51

ANT _

ANT _

O

N

1

2

3

4

5

6

7

8

PWR

5

1

ANT

_

ANT

_

ON

12345678

A

Dip Function Status Description

DIP 1 Close immediately OFF Close immediately o

ON Close immediately on:

The engagement and subsequent disengagement of the photocell when

closing, while opening or during the pause time causes the gate to re-

close immediately at least 3 s after full opening, regardless of the set

automatic closing time

DIP 2 Automatic closing OFF Automatic closing o

ON Automatic closing on

DIP 3 Step-step logic OFF 2 steps: step-by-step (term. 51 and radio) with logic in 2 steps (open -

close - open)

ON Step-by-step command (term. 51 and radio) with logic in 4 steps (open -

stop - close - stop - open - stop)

DIP 4 Apartment block OFF Apartment block o

ON Apartment block on (while the gate is opening, you cannot stop the

movement with a radio command or with inputs 51 (step-by-step) and

52 (pedestrian). With automatic closing on (DIP-switch 2 = ON) and the

gate open, an additional step-by-step command (terminal 51 or radio

command) renews the pause time and if input 51 remains engaged the

control panel suspends the pause count until the input is disengaged (for

connecting any coils or a timer)

DIP 5 Slowdown distance OFF Slowdown distance at 10% of the travel

ON Slowdown distance at 20% of the travel

DIP 6 Input 63 function OFF Input 63 congured as photocell (PH)

ON Input 63 congured as safety edge (BAR)

DIP 7 Action speed OFF Action speed high

ON Action speed low

DIP 8 Photo-test OFF Photo-test o

ON Photo-test on

At the start of each action, the control panel checks the operation of the

photocells. It requires specic wiring

7

RS16.P

EN

9 LED functions

-

+

PHC PHO STP MRX

PWR

-

+

P

HC

P

H

O

S

TP

MRX

PWR

-

+

PHC PHO STP MRX

PWR

SW1 SW2

S

W1

S

W2

SW1 SW2

LED Status Description

PWR OFF Mains power supply not present

ON Mains power supply present

MRX 1 blink Saving a new remote control

2 blinks Saving a remote control already in memory

3 blinks Deleting a remote control

4 blinks Radio memory full

5 blinks Attempt to store a remote control with a dierent code from the one used to set the receiver

10 blinks Complete deletion of the radio memory

51 OFF Step-by-step input (term. 51) not engaged

ON Step-by-step input (term. 51) engaged

52 OFF Pedestrian input (term. 52) not engaged

ON Pedestrian input (term. 52) engaged

61 OFF Stop contact (term. 61) open (engaged)

ON Stop contact (term. 61) closed (not engaged)

62 OFF Photocell engaged when closing (term. 62 open)

ON

Photocell not engaged when closing (term. 62 closed)

63 OFF Photocell or safety edge engaged (term. 63 open)

ON Photocell or safety edge not engaged (term. 63 closed)

SW1 OFF Limit switch 1 (corresponding to the right limit switch bracket marked DX) not used

ON Limit switch 1 engaged

SW2 OFF Limit switch 2 (corresponding to the left limit switch bracket marked SX) not used

ON Limit switch 2 engaged

10 Remote control programming

Note: Remote control programming can only be done with the automatic gate system stationary

Step-by-step programming

No. Pressing push button Signal

MRX LED Description

1MRX O Press and hold down the MRX push button for no more than 7 s

2MRX + remote control - With the MRX push button still pressed, press the button of the remote control to be saved

3- 1 blink Button of the saved remote control (new remote control)

2 blinks Button of the saved remote control (remote control already in memory)

Programming the pedestrian

No. Pressing push button Signal

MRX LED Description

1MRX + PRG O Press and hold down the MRX and PRG push buttons for no more than 7 s

2MRX + PRG + remote control -With the MRX and PRG push buttons still pressed, press the button of the remote control to be

saved

3- 1 blink Button of the saved remote control (new remote control)

2 blinks Button of the saved remote control (remote control already in memory)

Deleting a remote control

No. Pressing push button Signal

MRX LED Description

1MRX On steady Press and hold down the MRX push button for at least 7 s until the MRX LED comes on steady

2MRX + remote control - With the MRX push button still pressed, press the button of the remote control to be deleted

3- 3 blinks Deletion successful

Complete deletion of the receiver

No. Pressing push button Signal

MRX LED Description

1MRX Flashing light Press and hold down the MRX push button for at least 14 s until the MRX LED starts ashing

2- 10 blinks Complete deletion of the receiver

Note:

After deleting all the remote controls, the rst saved remote control congures the control panel to accept only remote controls with a rolling

code or only remote controls with a xed code.

8

RS16.P

EN

11 Troubleshooting

Problema Cause Solution

The automation system does not

work

No mains supply Check the power line switch

Blown fuse Replace blown fuse with others of the same value

Control and safety inputs not working Check the diagnosis LEDs (61, 62, 63 must be on)

You cannot save the remote con-

trols

Safety devices open 61, 62, 63 must be on

Batteries of the remote control discharged Replace the batteries

Remote control not compatible with the rst one saved The rst saved remote control congures the control

panel to save only rolling-code remote controls or only

dip-switch remote controls

Reached memory saturation Delete at least one remote control or add an external

receiver (maximum capacity 50 remote controls)

As soon as the gate starts, it

stops and reverses

Motor torque not sucient Increase the power with the trimmer

After a command the ashing light

blinks 6 times but the gate fails to

open

Photo-test check failed Check the electrical wiring (see section 4) and DIP-

switch 8.

Check the alignment of the photocells

The ashing light does not work

during the movement

No mains power supply and motors on battery operation Check the mains power supply

The gate moves at slowdown

speed

Probable 230 V AC mains failure Run 1 complete open/close action

The gate detects an obstacle

even when it is not there

Poor or no clearance between the pinion and rack Check the rack-pinion clearance

Force trimmer too low Raise force trimmer

Gate mechanics sti Service the gate

9

RS16.P

EN

EC DECLARATION OF CONFORMITY

(Declaration of incorporation of partly completed machinery Annex IIB Directive 2006/42/EC)

No.:ZDT00434.00

The undersigned, representing the following manufacturer

Elvox SpA

Via Pontarola, 14/A - 35011 Campodarsego

(PD) Italy

herewith declares that the products

CONTROL BOARD - RS SERIES

Articles RS16.P

are in conformity with the provisions of the following EU Directive(s) (including all applicable amendments) and that all of

the following standards and/or specifications have been applied

EMC Directive 2004/108/EC: EN 61000-6-1 (2007), EN 61000-6-3 (2007) + A1 (2011)

R&TTE Directive 1999/5/EC: EN 301 489-3 (2002), EN 300 220-3 (2000)

Machinery Directive 2006/42/EC EN 60335-2-103 (2003) + A11 (2009),

EN 13241 (2003) + A1 (2011), EN 12453 (2000)

He also declares that the product must not be commissioned until the end machine, in which it is to be incorporated, has

been declared in conformity, when applicable, with the provisions of Directive 2006/42/EC.

He declares that the relevant technical documentation has been constituted by Elvox SpA, drawn up in accordance with

Annex VIIB of Directive 2006/42/EC and that the following essential requirements have been fulfilled: 1.1.1, 1.1.2, 1.1.3,

1.1.5, 1.1.6, 1.2.1, 1.2.2, 1.2.6, 1.3.1, 1.3.2, 1.3.3, 1.3.4, 1.3.7, 1.3.8, 1.3.9, 1.4.1, 1.4.2, 1.5.1, 1.5.2, 1.5.4, 1.5.5, 1.5.6,

1.5.7, 1.5.8, 1.5.9, 1.6.1., 1.6.2, 1.7.1, 1.7.2, 1.7.3, 1.7.4.

He undertakes, in response to an adequately justified request from the national authorities, to present all the necessary

supporting documentation concerning the product.

Campodarsego, 29/04/2013

The Chief Executive Officer

Note: The contents of this declaration match what was declared in the latest revision of the official declaration that was available before this

manual was printed. This text has been adapted for editorial purposes. A copy of the original declaration can be requested from Elvox SpA

Viale Vicenza, 14

36063 Marostica VI - Italy

www.vimar.com

RS16.P installer EN 00 1804

Table of contents

Other Vimar Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Wayne-Dalton

Wayne-Dalton 8000 Series Installation instructions and owner's manual

Seip

Seip TM 60 installation instructions

Guardian

Guardian DCS 3/4HP owner's manual

PRIORY

PRIORY EUROPA operating & maintenance manual

Fac

Fac MULTITELESCOPIC Assembly instructions

DTM System

DTM System SWIFT6 Assembly manual for the installers

Avanti

Avanti SDO-21 TP/BP Installation instructions and user guide

Chamberlain

Chamberlain 8010 manual

Schartec

Schartec Move 600 Installation and operating instructions

Chamberlain

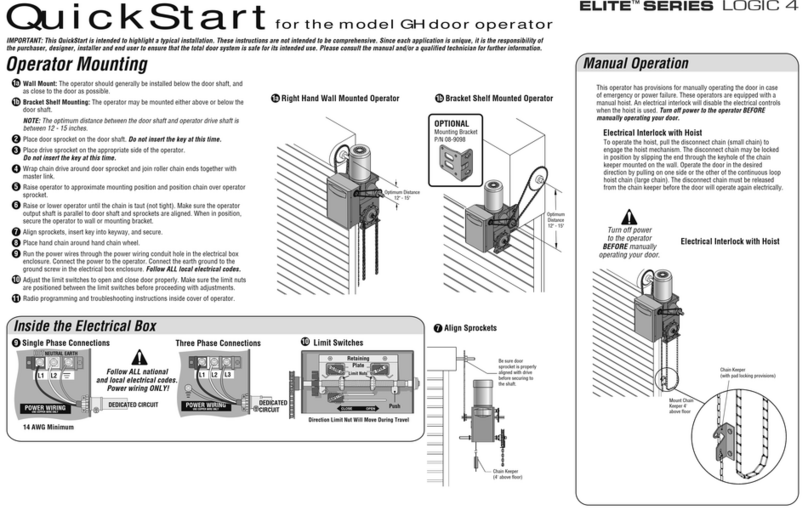

Chamberlain GH quick start guide

Chamberlain

Chamberlain LiftMaster Professional 5580 instructions

Chamberlain

Chamberlain Contractor Series manual