VPC MONGOOST-50® BASE

QUICK START GUIDE

BASIC OPERATION

●The VPC MongoosT-50® Base is compatible with the VPC Extensions. Extensions up to

150mm are supported, extensions larger than this are not recommended, especially when

combined with heavier springs.

●The VPC MongoosT-50® Base should be mounted with the included VPC U-Bracket. If this is

unsuitable, a custom mount can be created to connect directly to the existing 4 x VPC

U-Bracket mounting points. Different length screws should be used to account for the

difference between the original VPC U-Bracket and any custom solution. It is not

recommended to mount the base via the underside bolts. Any damage caused by a custom

mounting solution is not covered by the standard warranty.

●When adjusting the spring loading screws via the upper plate adjustment holes the minimum

allowed tension is when half of the joysticks deflection is free of any spring force. The

maximum allowed tension is achieved by roughly 25 clockwise turns. Over tensioning the

spring loading screws can result in the joysticks total deflection being limited. If you require

stronger spring tension, replace the axis compression springs for the heavier set.

●The VPC MongoosT-50® Base is a complex piece of equipment aimed at the experienced

user. Replacing the springs and cams can be a complicated process and if you are at all

unsure, please contact VPC directly for help to avoid damage to your set. User damage while

attempting to make adjustments to the base is not covered by the manufacturer warranty

and would be subject to a repair cost.

REPLACING THE AXIS COMPRESSION SPRINGS

1. Disconnect the base USB cable from the PC.

2. Remove the base from the VPC Desk Mount or other mounting method.

3. Remove the attached grip from the base.

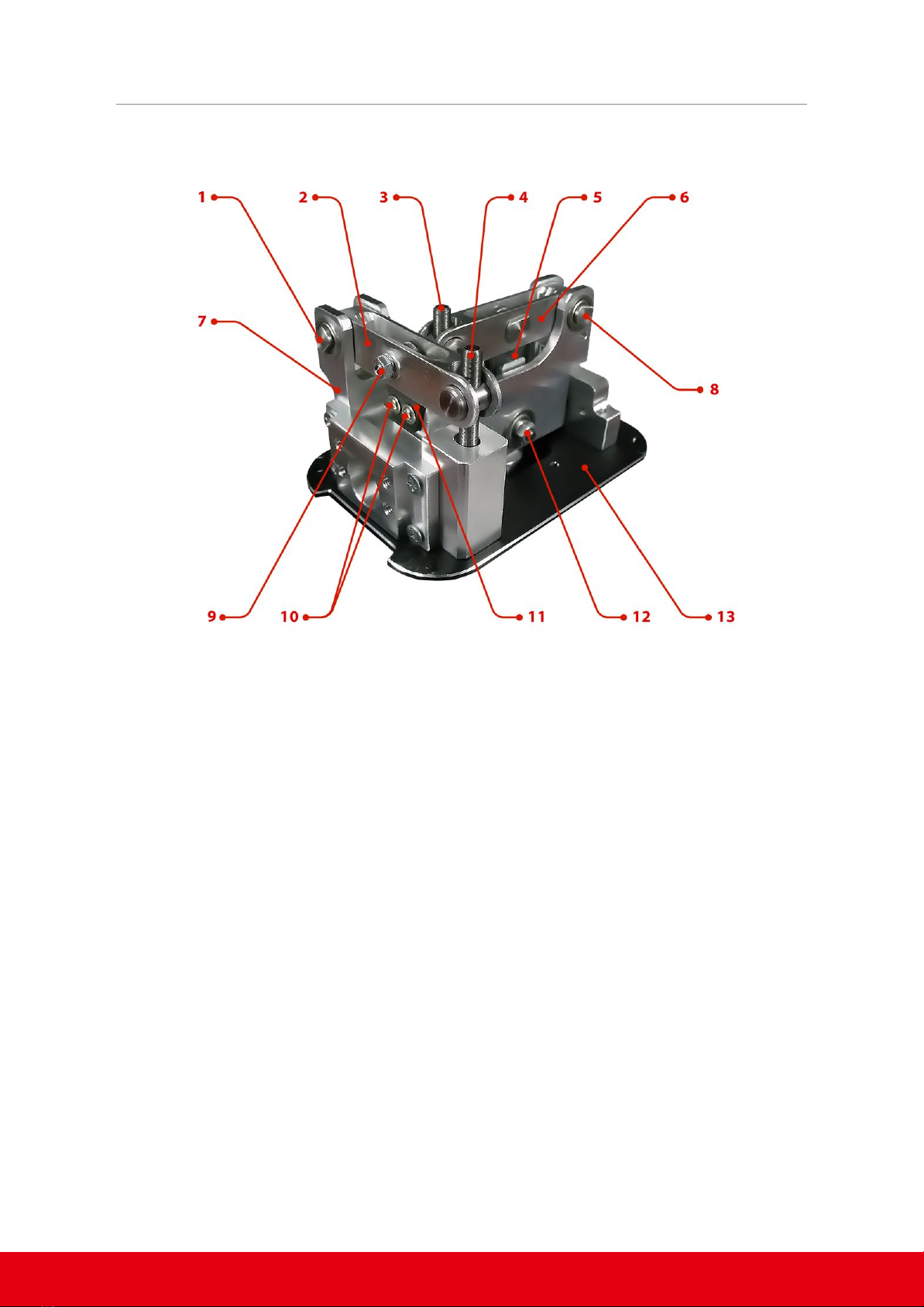

4. Loosen the spring loading tension on the Pitch (FIGURE 1 - #6) and Roll (FIGURE 1 - #7) axes via

the adjustment holes on the upper plate.

5. Remove the 4 x M4 screws from the lower plate (FIGURE 1 - #13). Store the lower plate in a

safe location to avoid damage.

6. Remove the 4 x M4 screws from the upper plate (FIGURE 1 - #1).

7. Remove 5 x M3 screws affixing the rubber boot surround to the upper plate.

8. Remove the 4 x M4 screws affixing the upper plate to the gimbal structure (FIGURE 1 - #3).

9. Completely remove the rubber boot (FIGURE 1 - #5) and upper plate (FIGURE 1 - #10) over the

grip stem (FIGURE 1 - #4).

10. Completely loosen the spring loading screw for the axis you wish to replace the spring on.

While you do this, hold the cylindrical nut from the lower side of the base.

11. With the spring loading screw completely loosened, remove it from the gimbal and you will

be able to remove the currently equipped spring. Replace the spring with your desired

choice.

12. Place the spring loading screw with the newly equipped compression spring, back into its

recess.

13. While holding the cylindrical nut from the lower side of the base, hand tighten the screw

until the spring starts to become loaded.

14. Reassemble the base by repeating the steps in reverse from step 9.

6