Visionis VIS-440 Series User manual

Electric Automatic Door Opener

VIS-440 Series

Installation Manual

www.visionistech.com

Table Content

1 Technical Parameters

2 Components

3 Installation Steps

3.1

Installation of bottomplate

3.2

Installation of bottom plate

3.3

Installation of pull bar

3.4

Installation of pull bar

3.5 Installation of push bar

1

2

4-12

4

5

6-7

8

9

3.6 Installation of push bar 10

3.7 Finished installation

3.8 Mechanism and cover installation

4 Wired diagram

4.1

Terminal details of controller

4.2

Data setting

4.3

Connection of commonly used and special function

11

12

13-15

13

13

14-15

5 Remote Functions 16

6 LED display feedback 17

7 Trouble shooting 17

1. Technical Parameters

Dimensions (LWH)

515.62*78.74*114.3mm (20.3*3.1*4.5 Inches)

Weight

17.7lbs

Ambient temperature

-20°C~ +50°C (-4°F~ 122°F)

Operation voltage

AC 100V -127V

Power supply external consumption

24V DC (±10%), 3A

Door opening angle

Max 120°

Opening speed

45°/S

Closing speed

45°/S

Hold-open time

0-60S

Protection class

IP42 Indoor use only

mm=Door width

kg=Door weight

Suitable range

Limit range

mm

2000

1500

1000

80 120 160

100 140

180

kg

200

1

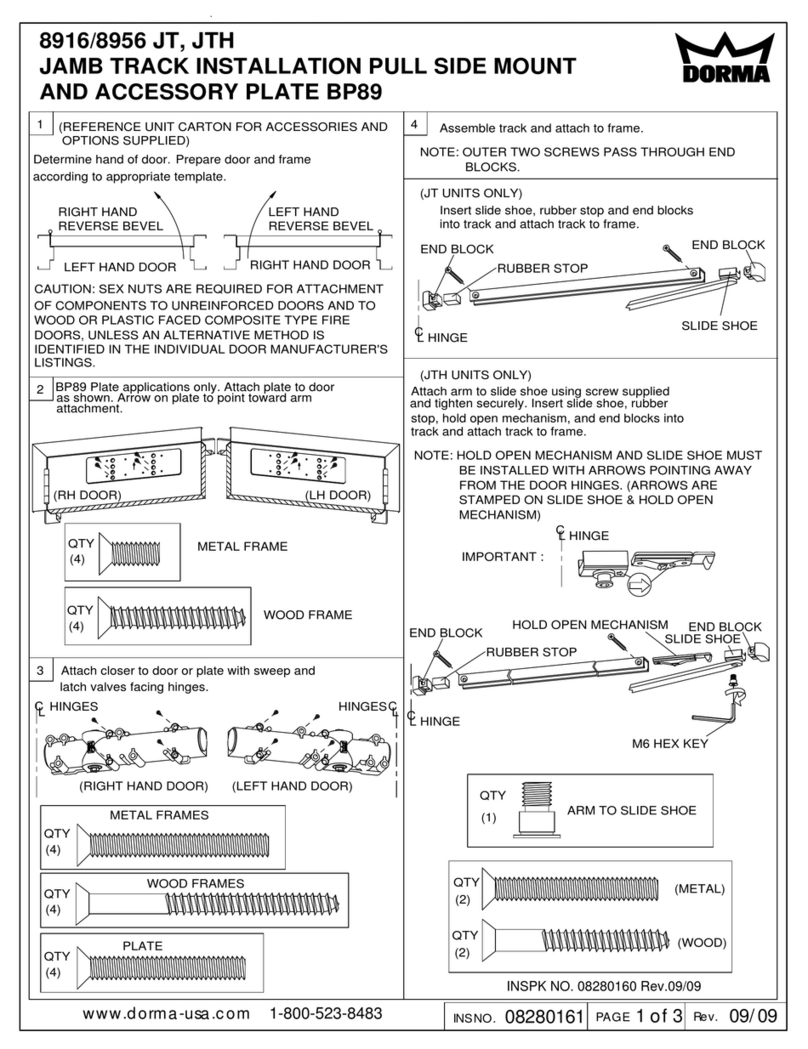

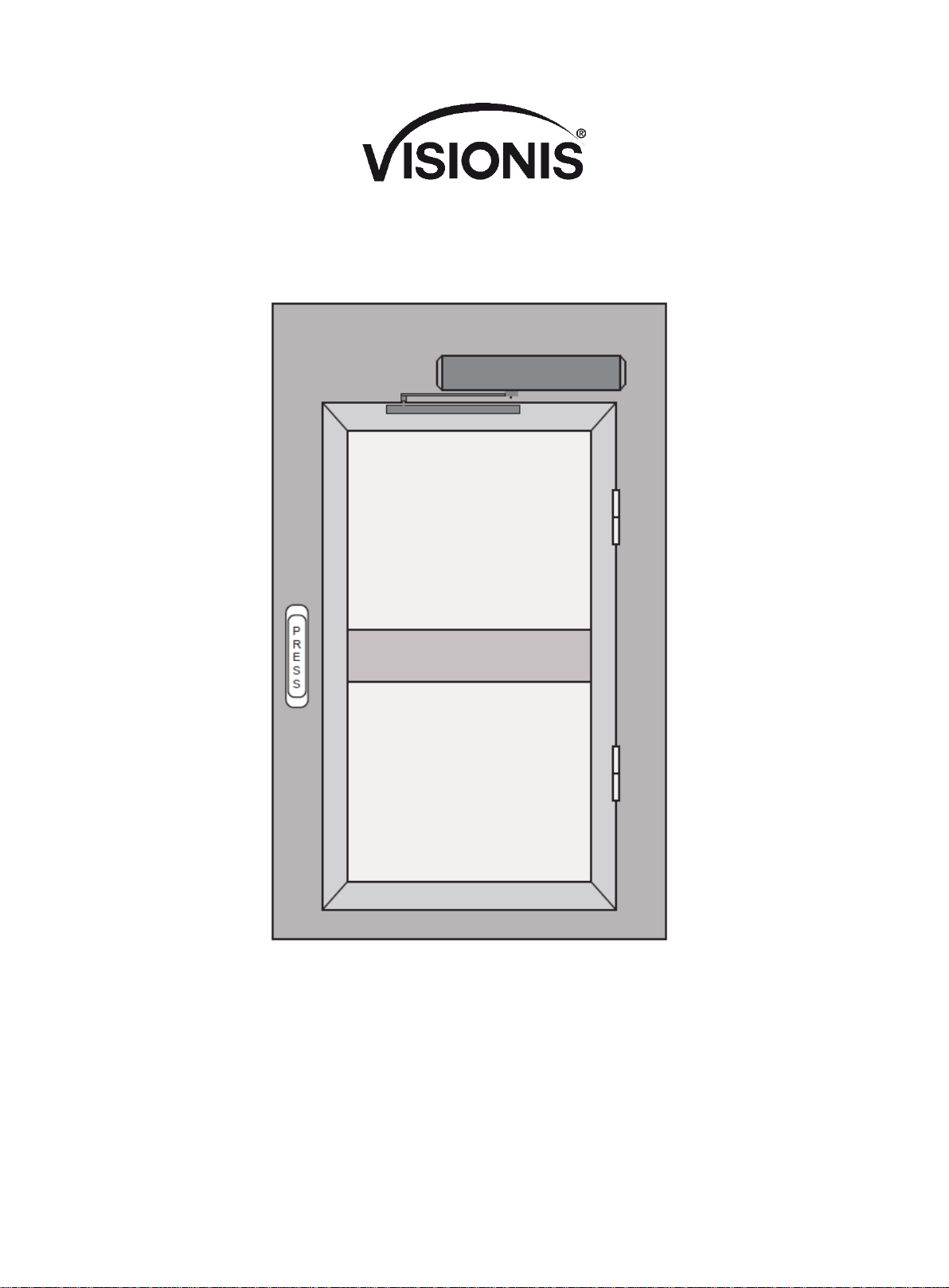

2. Components

Bottom plate

Pull bar (inswing)

Push bar(outswing)

Cover

Pull guider

Mechanism

Installation Screws

Allen wrench

Door sticker

Power cord (AC)

Note: Only one type of door

bar comes with every kit

Connect the AC power cable

to 110V input

X 2

X 8

2

Safety devices should be in place and operational.

Have door adjusted as recommended in Owner’s

Manual if necessary.

Have door inspected at least annually by a certified

technician.

TYPICAL USED TOOLS

.

If you choose to use no locks or any other

type of locks that is not a door strike, this

latch must be remove for proper operation.

3

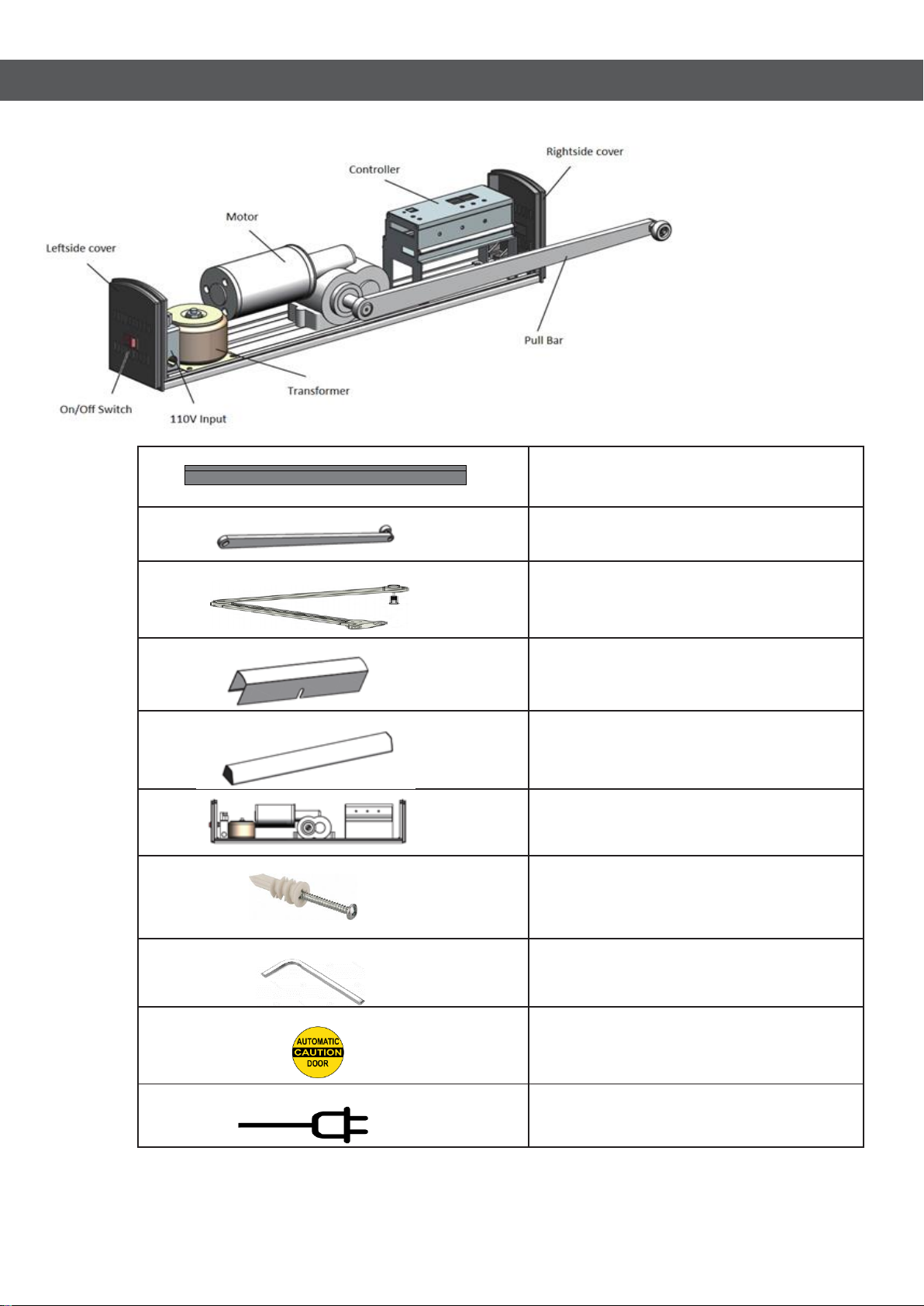

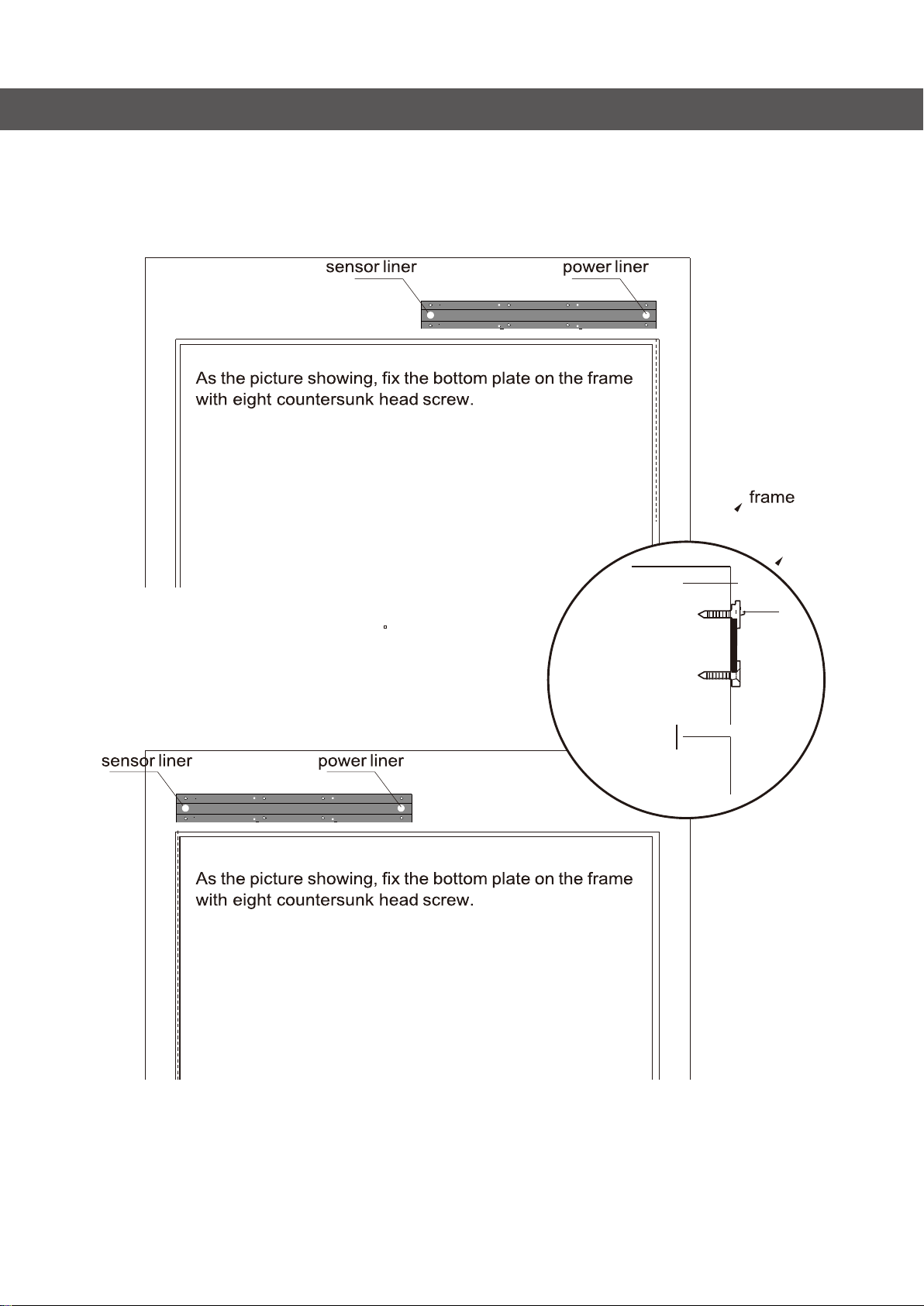

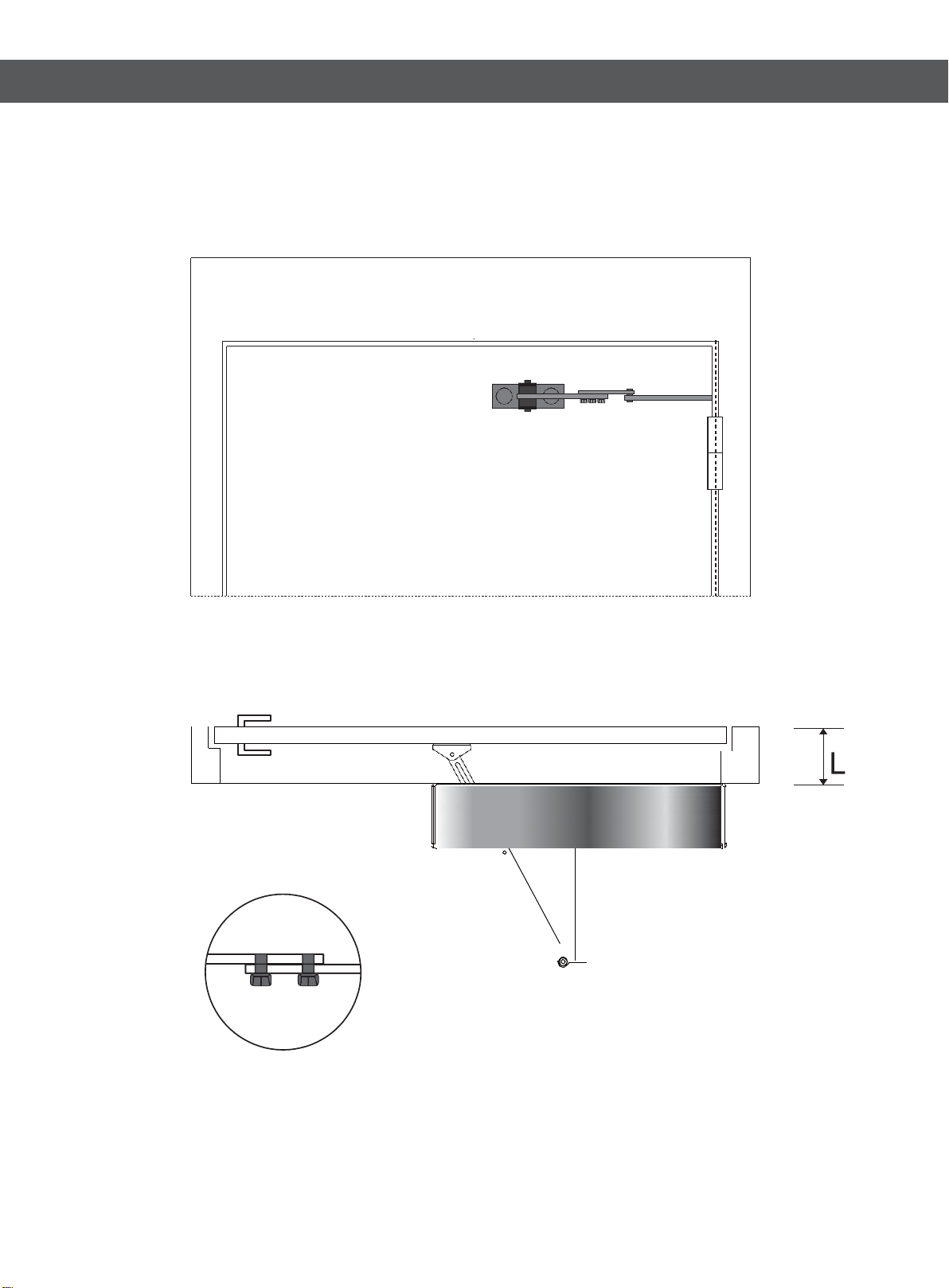

3.1

Installation of bottom plate

Pull bar type (inswing)

3. Installation Steps

30

4

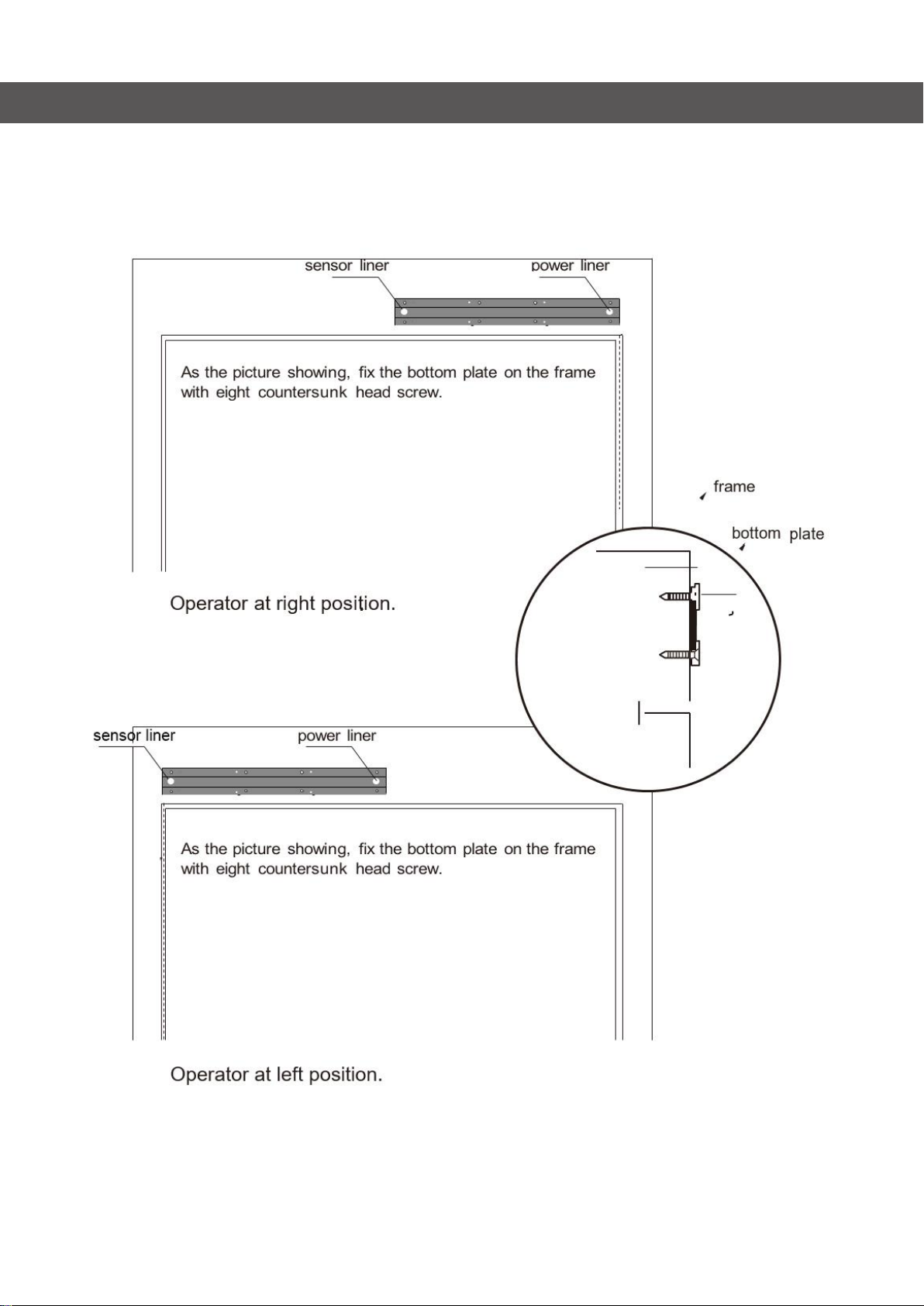

3.2

Installation of bottom plate

Push bar type (outswing)

plate

Operator at left position.

bottom

Operator at right position.

3. Installation Steps

5

3.Installation Steps

3.3

Installation of pull bar guider (inswing)

Operator at Right position Operator at left position

1. Open the door to 90 degree before installation put the slider of pull bar into groove

2. Fix the pull bar installation plate according to the picture

3. Adjust the position of slider installation plate make sure the wheel is at the

Middle of groove as the picture shown

4. Keep the position of installation plate tighten the first screw at the axis of door

5. Close the door, repeat the step 3,tighten the second screw at another side

6. Manually open and close several times make sure the pull bar is working perfect,

If there is resistance please adjust the installation plate of pull bar again

7. Tighten the last screw

6

3.3 Installation of pull bar guider (Inswing Door)

A.

Right position

Door leaf

Fix the pull bar on door leaf with

3 pcs self-tapping screw.

Adjust the opening angle

by position stopper.

position stopper

3. Installation Steps

7

3.4 Installation of pull bar guider

B. Left position

Fix the pull bar on door leaf with

3 pcs self-tapping screw.

Door leaf

Adjust the opening angle

by position stopper.

position stopper

3. Installation Steps

8

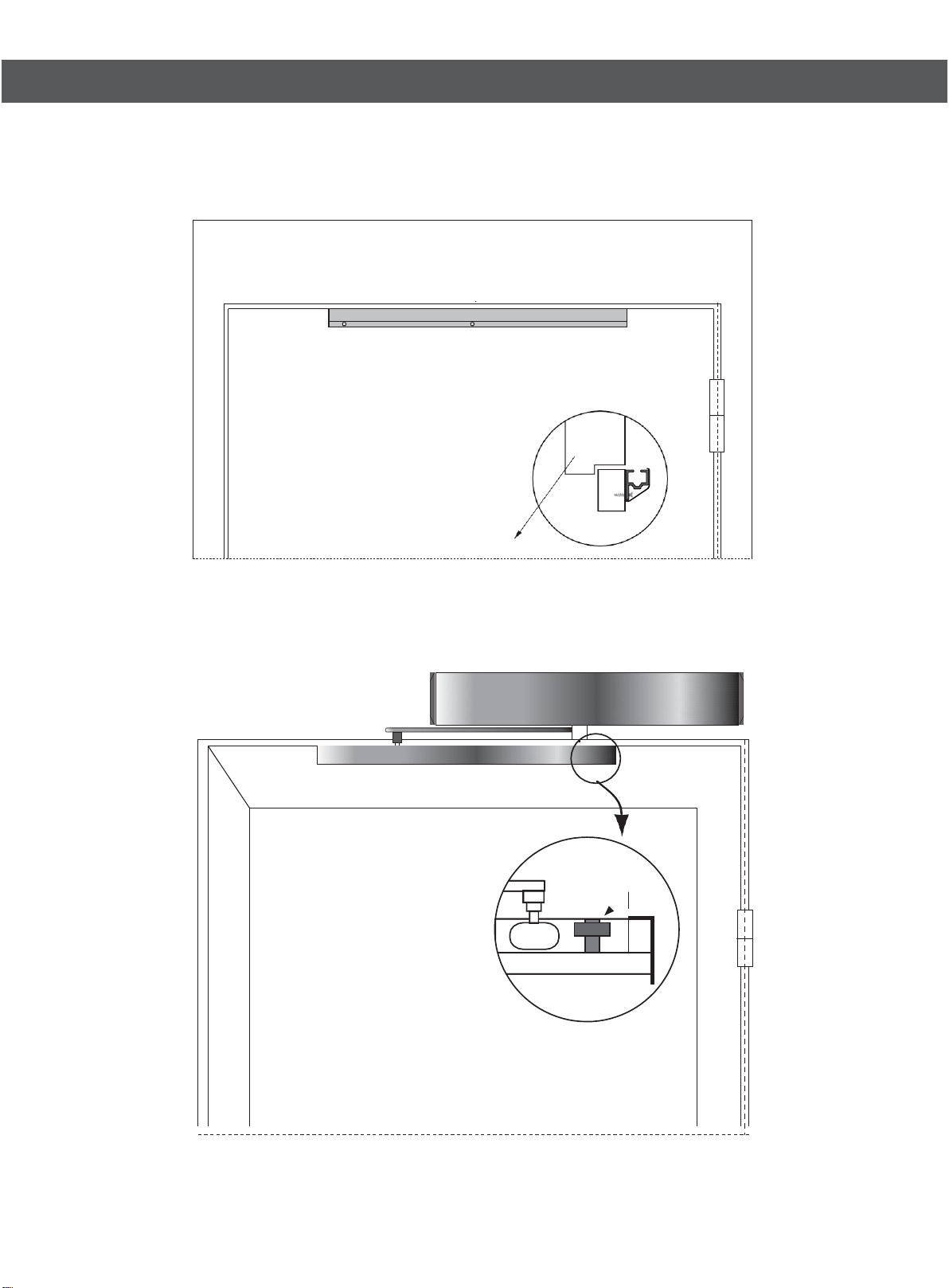

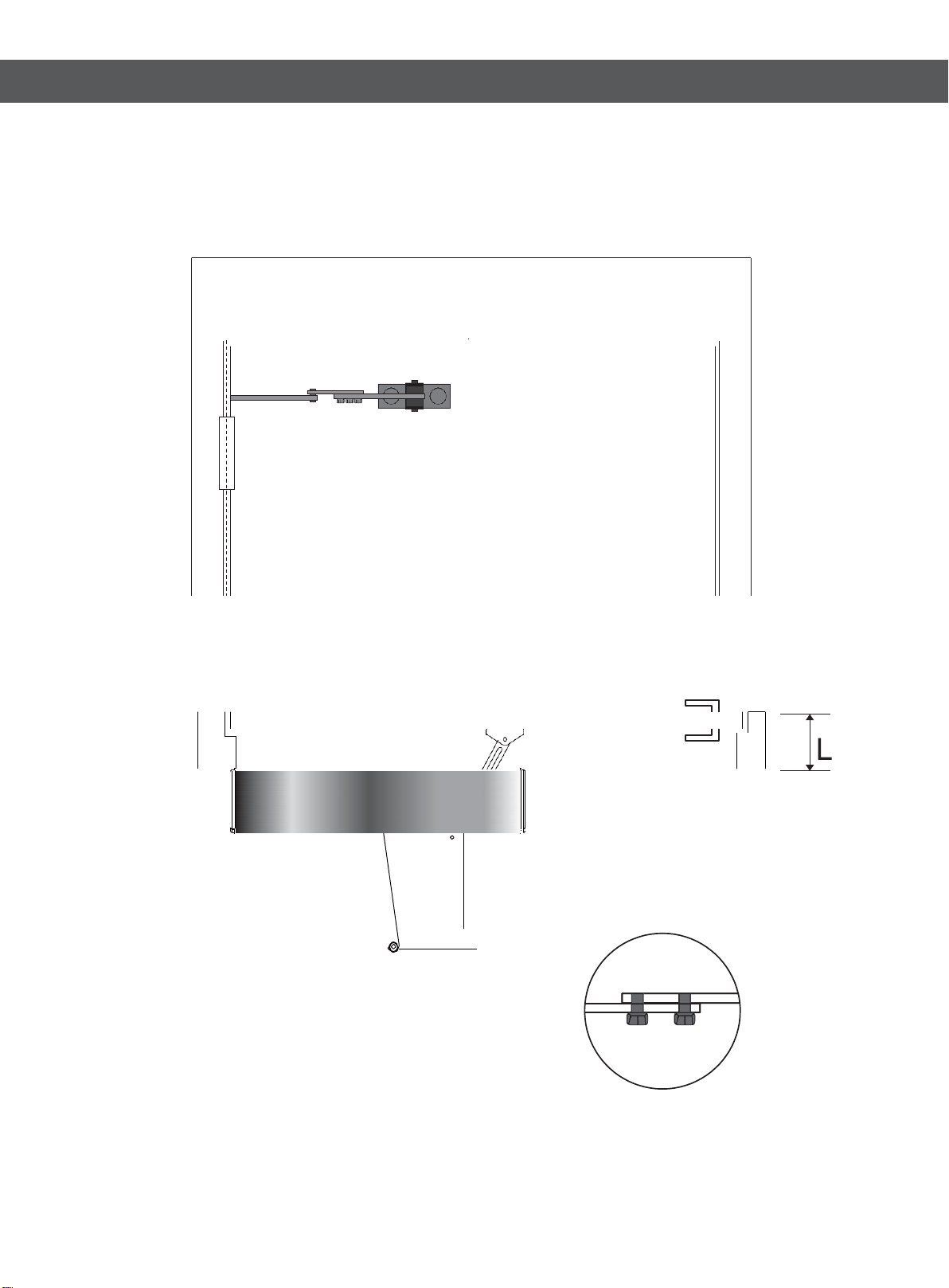

3.5 Installation of push bar (Outswing Door)

Adjust the push bar length by two screw according to the door frame’s depth(L).

3. Installation Steps

Fix the bottom of push bar to door leaf

9

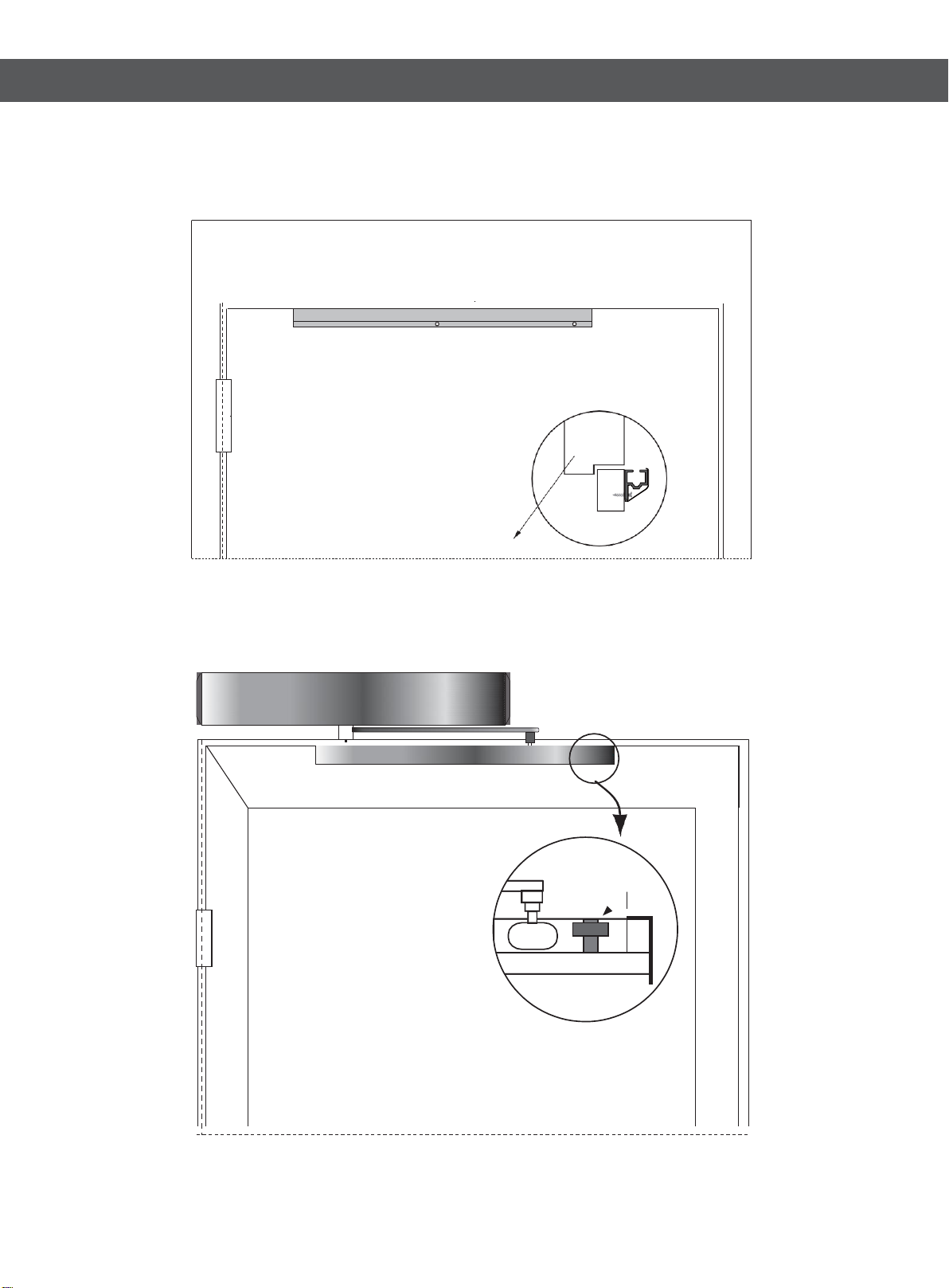

3.6 Installation of push bar

B. Left position

Adjust the push bar length by two screw according to the door frame’s depth(L).

3. Installation Steps

Fix the bottom of push bar to door leaf

10

3.7 Finished installation

Pull bar: Door leaf open toward inside (same direction as operator)

Operator

Push bar: Door leaf open toward outside (opposite direction as operator)

operator

3. Installation Steps

11

Note: you may have to

install a door stopper if there

isn't one or a wall to stop the

door after opening.

3. Installation Steps

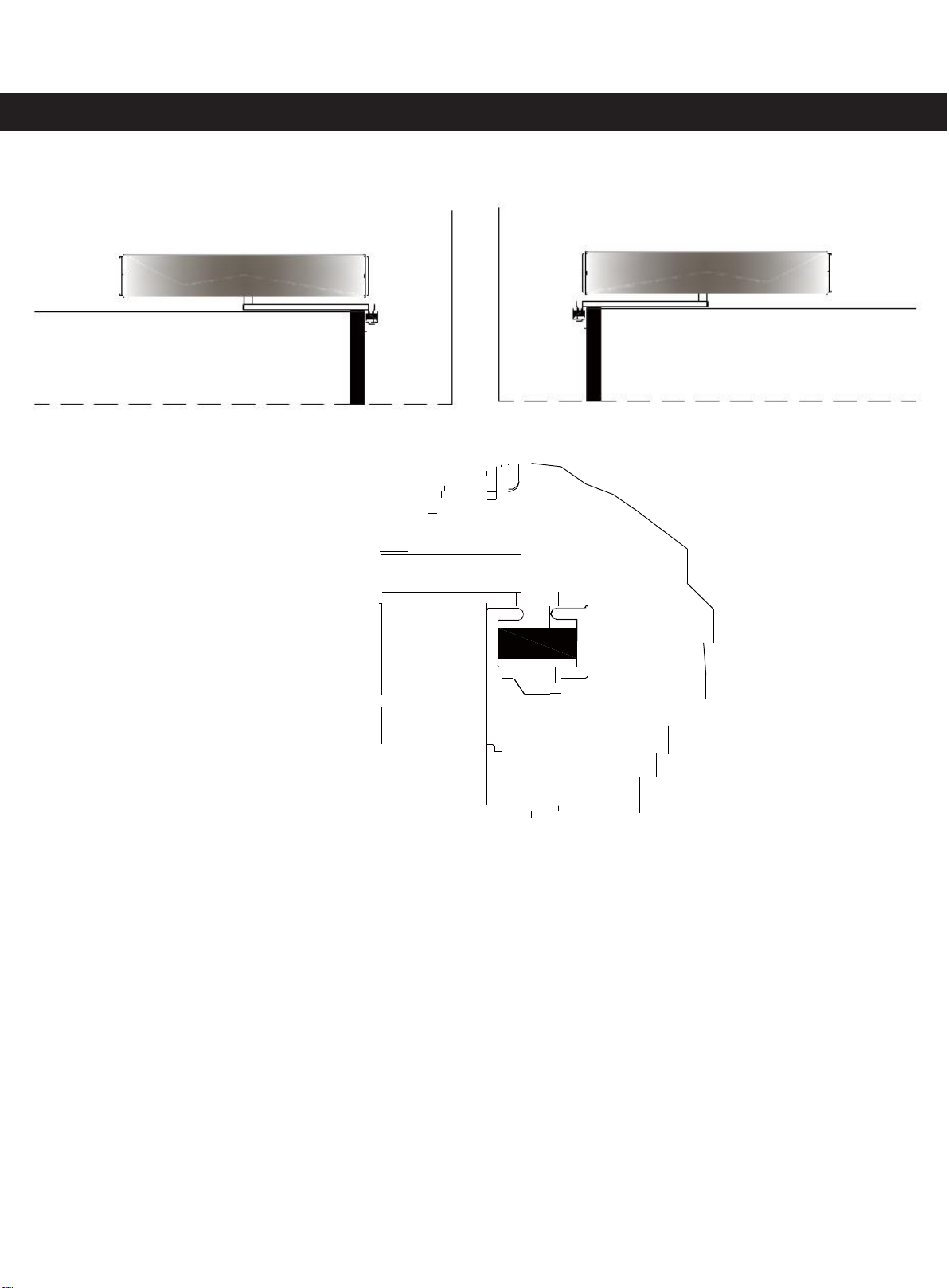

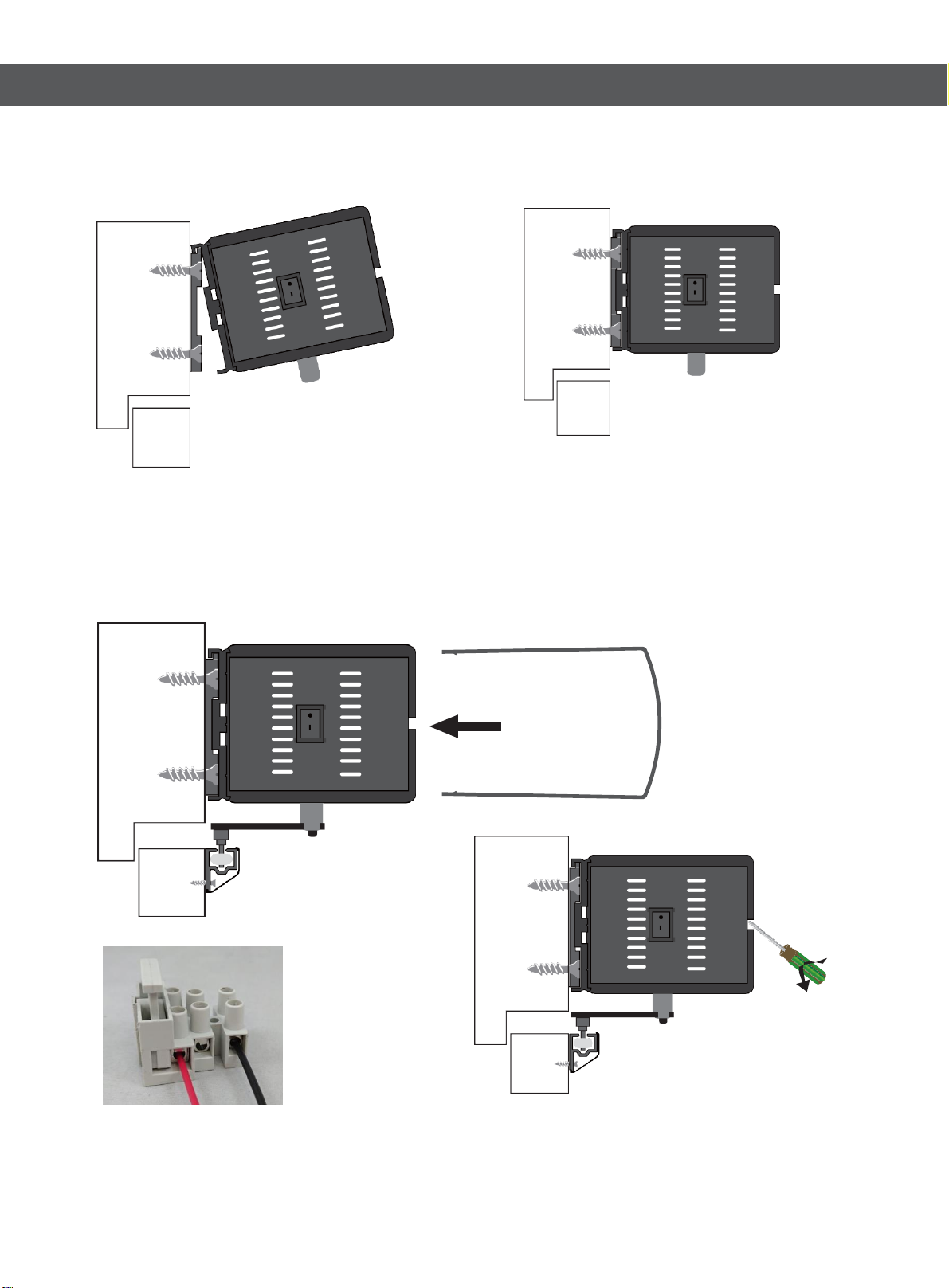

3.8 Mechanism installation

Note: First step is to remove the 8 mounting screws with Allen wrench. Separating the

Bottom plate from the mechanism, to be able to mount it on the wall

Hang the mechanism on the fixed base cover with screws.

Assemble and disassemble of the mechanism cover.

Note: Use a small

flathead screwdriver to

open the cover of the

mechanism

Note: Your power cord will have three cables, you will

only connect two. The green cable must be cut off and

the two remaining white and black cables go connected

into the terminals *Make sure the equipment switch is set

to the off position.

12

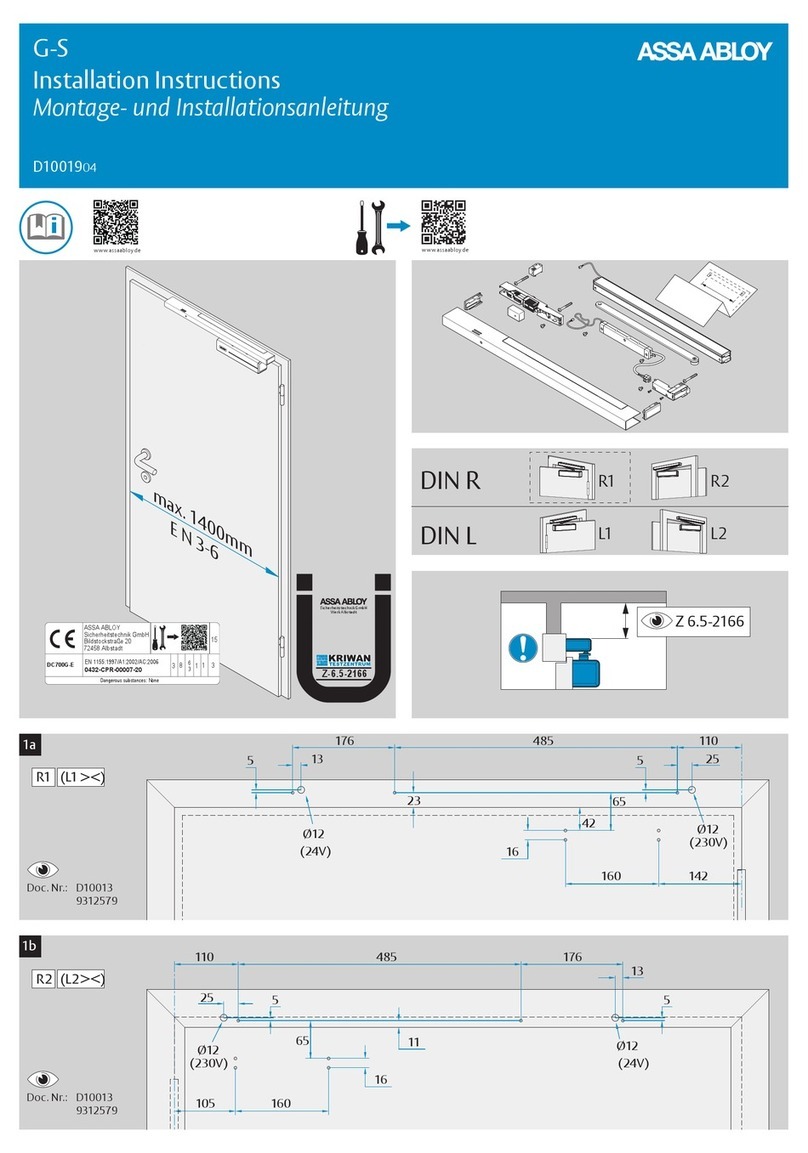

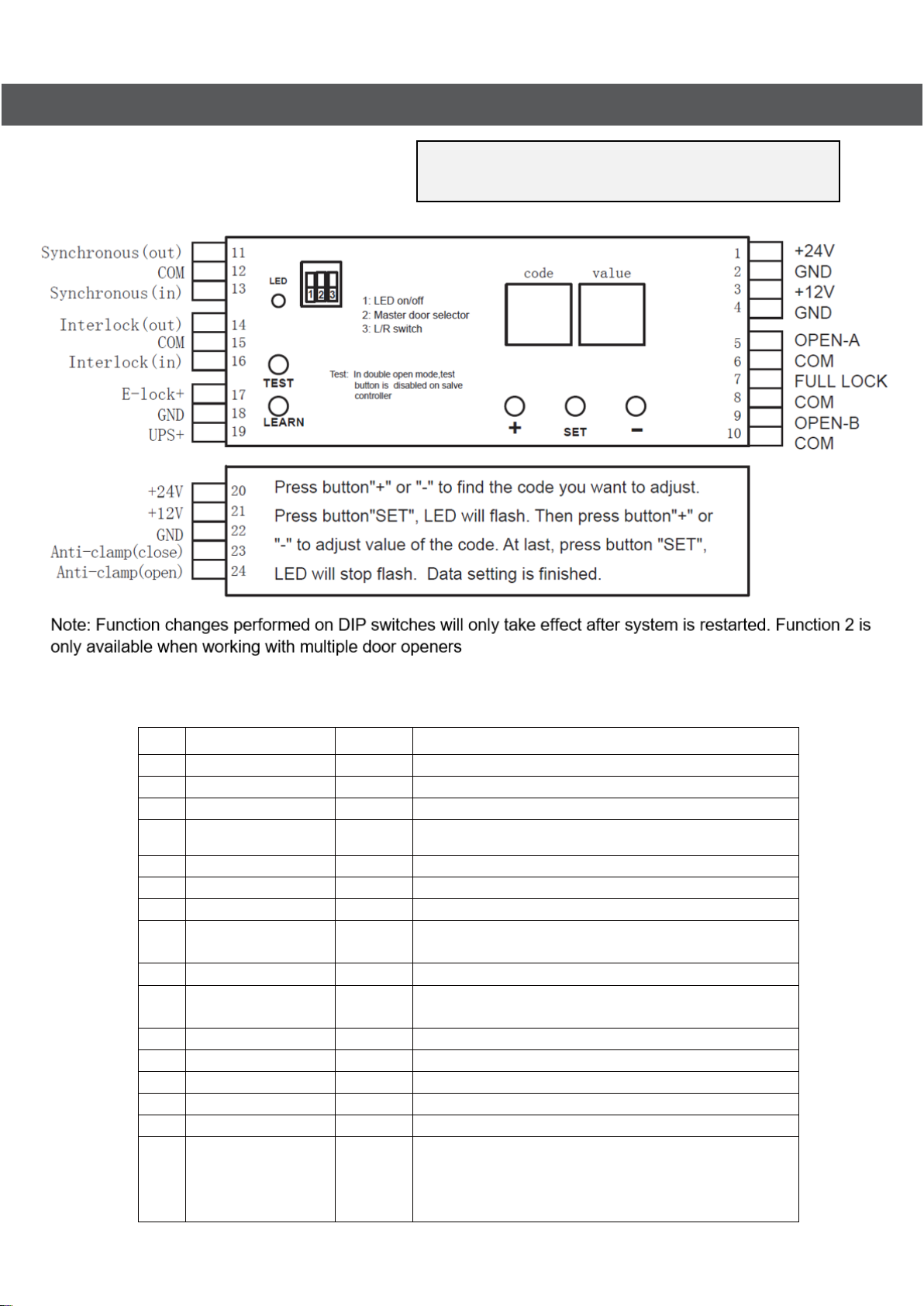

4. Wired Diagrams

4.1 Terminal details

4.2 Data setting

code

Setting range

Default

description

01

30-99

60

Opening speed(velocity to open)

02

30-99

50

Closing speed(velocity to close)

03

1-30

10

Delay opening speed (slowdown of door before full open status)

04

1-30

10

Delay closing speed (slowdown of door before full close

status)

05

10-50

30

Delay opening angle

06

10-50

30

Delay closing angle

07

0-60

2

Hold-open time 0-60s *time door is open after request

08

0,1,2...8

3

Starting delay time (0-4s,1=0.5s,when lock function

working)

09

0,1,2...8

2

Locking delay time(0-4s,1=0.5s)

10

0,1

1

Locking type (0 :lock by remote; 1 auto lock when

closed )

11

0,1

1

Push to open function(0:working,1 :not working)

12

1,2,3,4,5

3

Obstacle detection optimized for exterior(wind loads)

13

1,2,3,4,5

3

Auto-locking force

14

1,2,3,4,5

3

Anti-collision force

15

5-30

15

Auto-learning speed

16

0,1,2...10

2

Working interval between master and slave door (0-1s,

1=0.1s)

On master door. The setting is working when closing ;

On slave door. The setting is working when opening 。

13

NOTE: This product can be adjusted to work in either left or right

doors. To change the orientation of the motor Please use DIP

switch 3 located on the controller.

4. Wired Diagram

Inter-lock

24G Microwave sensor

14

4. Wired Diagram

Access Control Reader/Keypads (Stand-alone)

Access Control Panels (ETL & DLX Series, VIS-3013)

Wiring connection of electronic bolt lock

18. GND

17. Electronic lock+

Anti-clamp sensor when opening

24. Anti-clamp

22. GND

22.

GND

20. +24V

Anti-clamp sensor when closing

23.

Anti-clamp

22. GND

22. GND

20. +24V

+24V

GND

COM

NO

+24V

GND

COM

NO

15

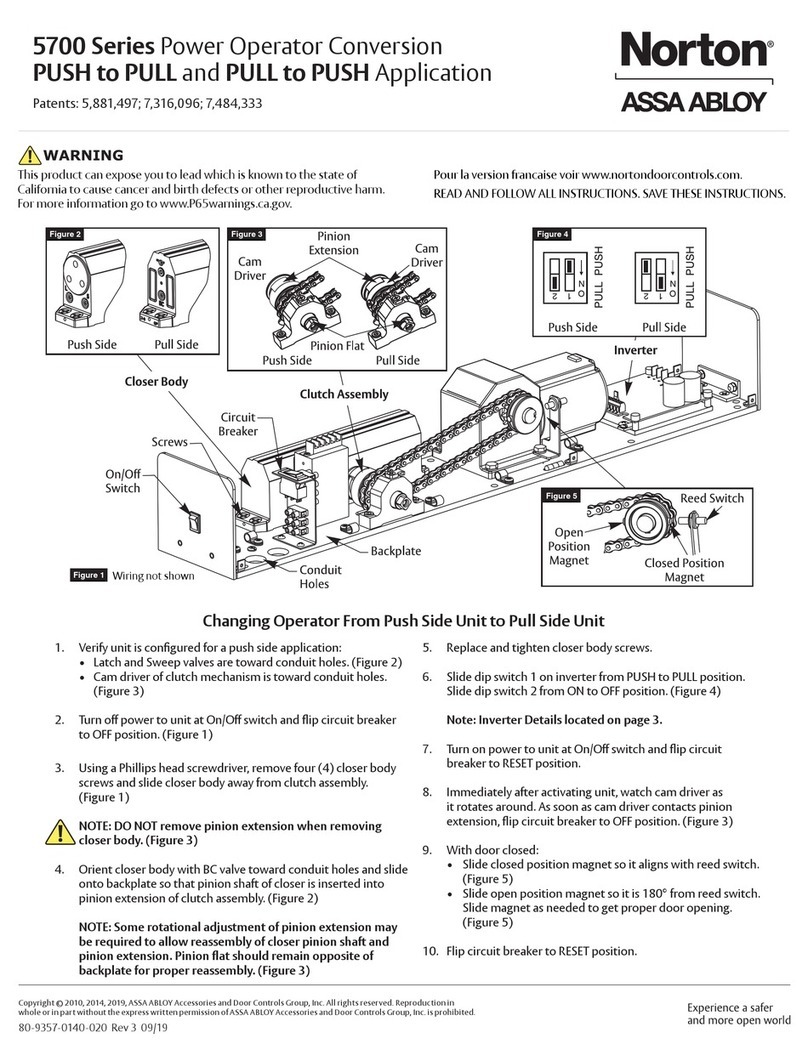

5. Remote Functions

Operation of remote control

VIS-8016:

A:

Always open

B:

Closed

C:

Automatic open/close

D:

Fulllock

Add the remote :press the learning button on controller till the indicator turn from green to

red,then release the learning button and press A button on remote,the indicator turn from

red to green alternately 3 times,learning successful.

Delete the remote:press and hold the learning button after 5seconds,the indicator turn from

green to red and turn to green again press A button on the remote the he indicator turn

from red to green alternately 3 times all the remote memory is deleted (attention,

please hold he learning button when you delete the remote memory).

Wireless push button :Added and deleted wireless push button is same as remote.

Please check the DIP switch if it‘s same as the image shown during

setting process).

Notes:

1. Receiver has beenbuilt-in.

2. Lock grades:open A>full lock>open B.

It means when full lock function working, it lock accessories connected to open B, but

can't lock accessories connected to open A.

3. Exit only function:

Connect outside sensor or button to terminal “Open-B", connect inside sensor or button to

terminal "Open-A”. Then press "full lock" button on remote.

4.When double open, the transmitter should learn both operators together.

5.In double open mode accessories should connect to both controller (parallel connection).

A B

C D

ON

1 2 3 4

16

6. LED Display Feedback

Singleopening

Double opening

LED display

Details

LED display

Details

Dr11

No problem.

Dr12

Master door

Dr12 or Dr13

Terminal 11 and 13 are not

connected. (They should be

connected when single opening)

Dr13

Slave door

Er01

Over current protection for Controller.

Er01

Over current protection for Controller.

Er02

Motor has problems.

Er02

Motor has problems.

Er03

Synchronized wired problem.

Er04

Master door and slave door settings

problem.

7. Trouble Shooting

Symptoms

Causes

Items Checked

Remedies

Door opened or

closed

un-smoothly

Opening/closing speed is

set too slow

check the opening/closing

speed

speed up the opening/ closing

speed

learning speed is too fast

check the learning speed

slow down the learning speed

Too much resistance

check whether there

is something on the

door's working way

clear the obstacle away

Hit the door frame

suddenly when

closing, doorstop

suddenly when

opening

Buffer speed when

opening/closing is too fast

slow down the buffer speed

when opening/closing

Position stopper isloosen.

Fix the stopper.

Door doesn't work

No power

check the power

switch, connection

terminal from motor to

controller

connect the power

learning speed is tooslow

speed up the learning speed.

Door is locked

check whether the door is

locked.

un-lock the door

Obstacle in the pull bar's

guider.

check the pull bar guider

remove the obstacle

Resistance force is too

strong.

Power off, push the door

leaf. Make sure thedoor

work smoothly.

17

Other manuals for VIS-440 Series

1

Table of contents

Other Visionis Door Opening System manuals

Popular Door Opening System manuals by other brands

KALE

KALE KD-002/30-220 User & installation manual

Entrematic

Entrematic Ditec VALFM installation manual

Entrematic

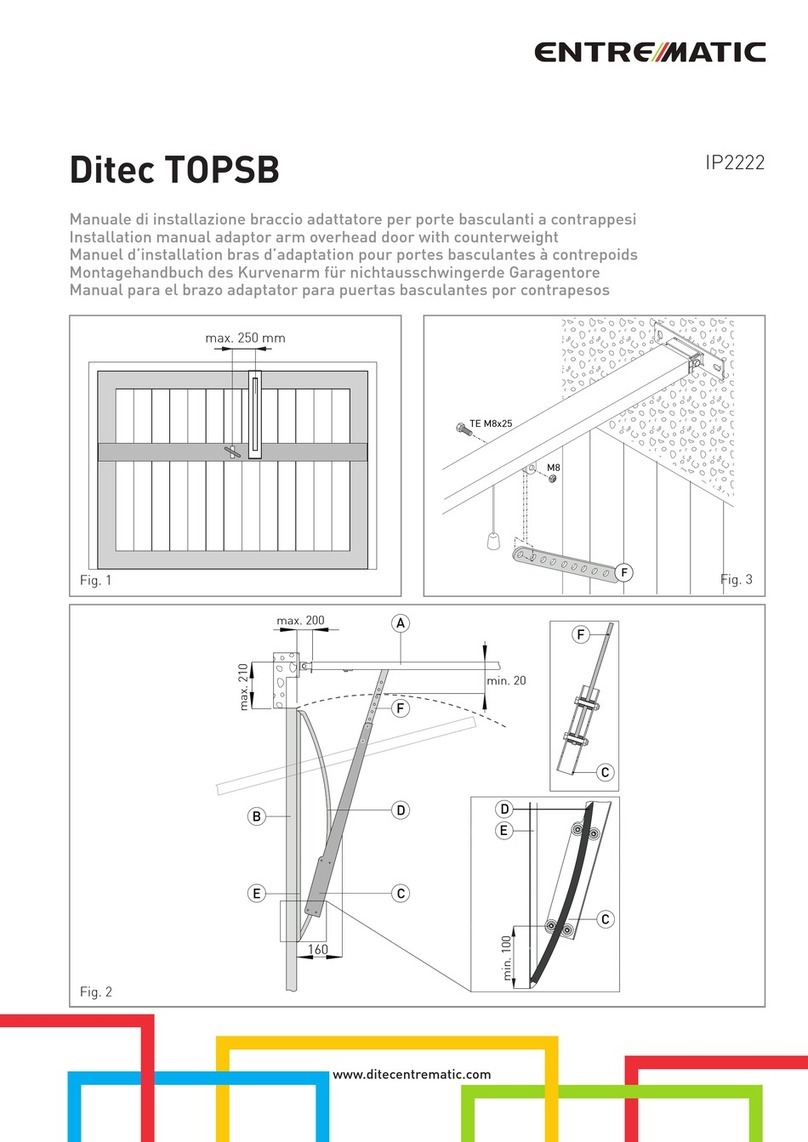

Entrematic Ditec TOPSB installation manual

Entrematic

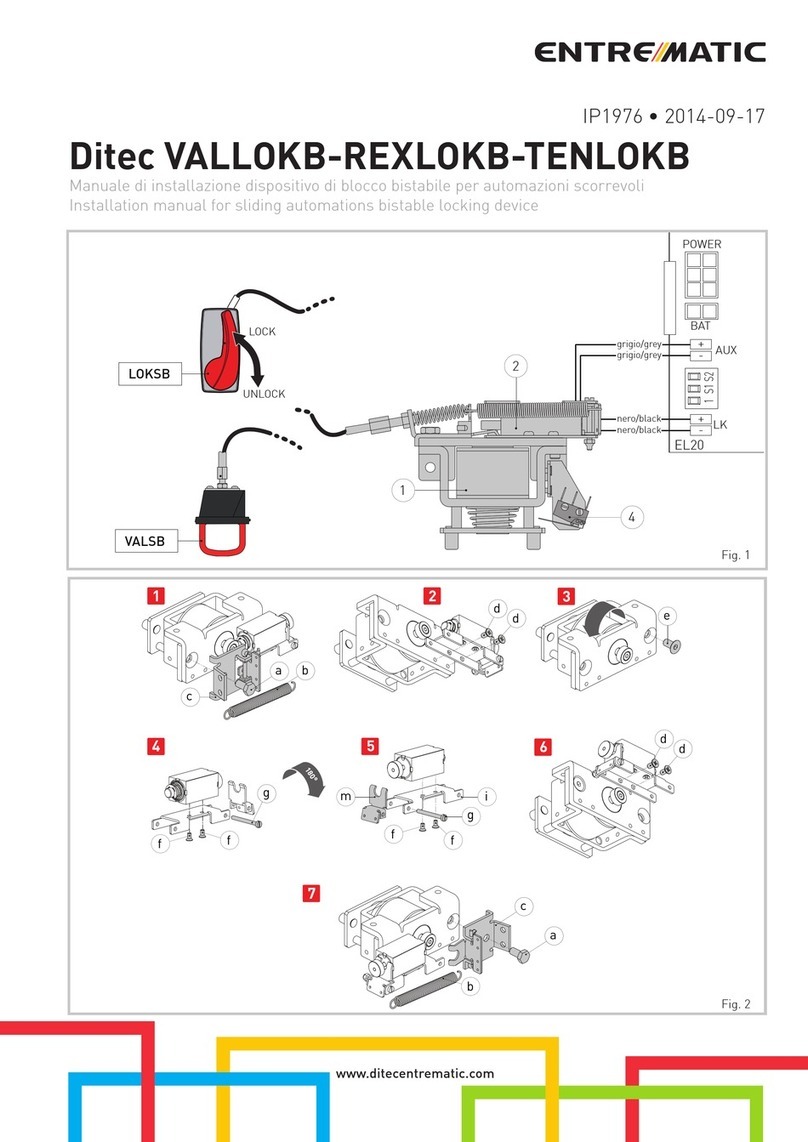

Entrematic Ditec VALLOKB installation manual

Keyautomation

Keyautomation LEV3281LT Instructions and warnings for installation and use

Synergy Hardware

Synergy Hardware S300 Series Fixing instructions