4. TRANSFORMER INPUT CONNECTIONS (Input • Output)

1. Activation Switch (2 supplied with unit)

Lead output wires of activation device such as sensor switch, button etc., to be

connected to this input plug in track. Two 5m 4-core wires will be supplied with the

correct terminal connection to plug into the input.

- The door opens and closes when signalled from the activation device.

2. Lock Switch – (If optional lock is attached)

Lead output wires of activation device such as sensor switch, button etc., to be

connected to this input plug in track. A single 5m 2-core wire will be supplied with

correct terminal connection to plug into the input.

- When the lock switch is turned ON the lock will engage

- Lock will automatically disable, and the door opens when the activation switch is

on. Lock will automatically re-engage when closed.

- When the Lock switch is turned OFF the door can be pushed open.

3. Safety Beams – (Optional upon order)

Safety beams can be applied to the auto door unit upon request. These will be

fitted/wired in position on the cavity and auto head prior to leaving the factory.

- Only during a closing movement, the door will open and stay open while the

beam lines are broken (When something is in/crossing the walkway).

- The beams are only active while the door is open/closing. When the door is fully

closed, breaking the beams will not open the door.

4. Advanced Features – (Optional upon order)

The following advanced features can be applied to the auto door unit upon request.

The wire loom - L003 will need to be ordered from CS FOR DOORS to be able to

wire/connect the activation devices to the controller:

• OUTPUT 24VAC 0.5A

24V AC is supplied from this output for an auxiliary device requiring power.

- Terminal A and H on advanced input plug (A is line, H is neutral)

• BREAKAWAY

When breakaway is active, power is cut to the motor and the door is operated as a

manual slider. Power is still connected to the controller and motor acts as a soft-

open/close device to avoid pinching fingers when operating the door by hand.

When the switch is turned off the door resumes normal operation.

- Connect activation device to Terminal C and G on advanced input plug.

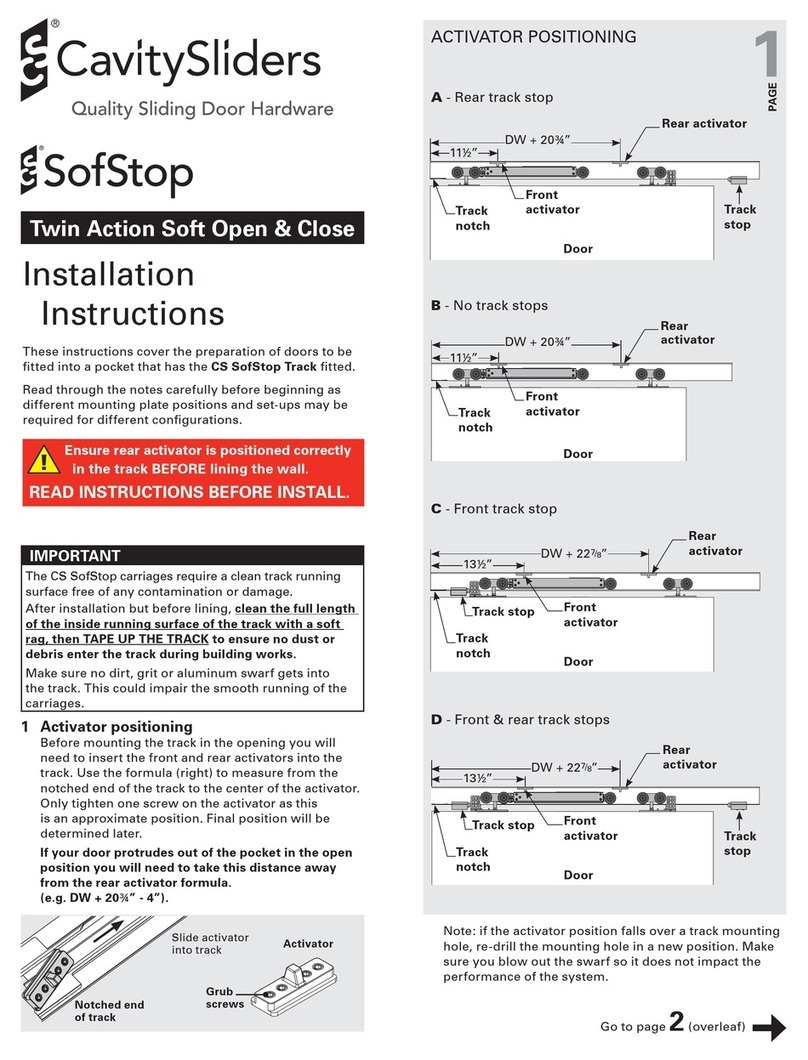

REVERSIBLE PART

SEE INSTRUCTIONS

Instructions & Support: www.csfordoors.co.nz/Technical/AutoCav-Support

BELT TENSION: Do not over-tighten.

Turn bolt +direction until belt is

parallel/straight between pulleys.

Add extra 3 full turns for correct

tension.

BELT TENSION: Do not over-tighten.

Turn bolt +direction until belt is

parallel/straight between pulleys.

Add extra 3 full turns for correct

tension.

TO ATTACH BELT

• Attach belt to belt clamp bracket

• Place over motor pulley

• Place over tensioner pulley

• Tighten belt to correct tension

TO REMOVE BELT - follow steps above in reverse

Bend up

locking

tab TENSION

Tension

Bolt

LOOSEN

Tensioner

Pulley

Top

Screws

(3)

Belt

Front

Screws

(2)

Belt Clamp

Bracket

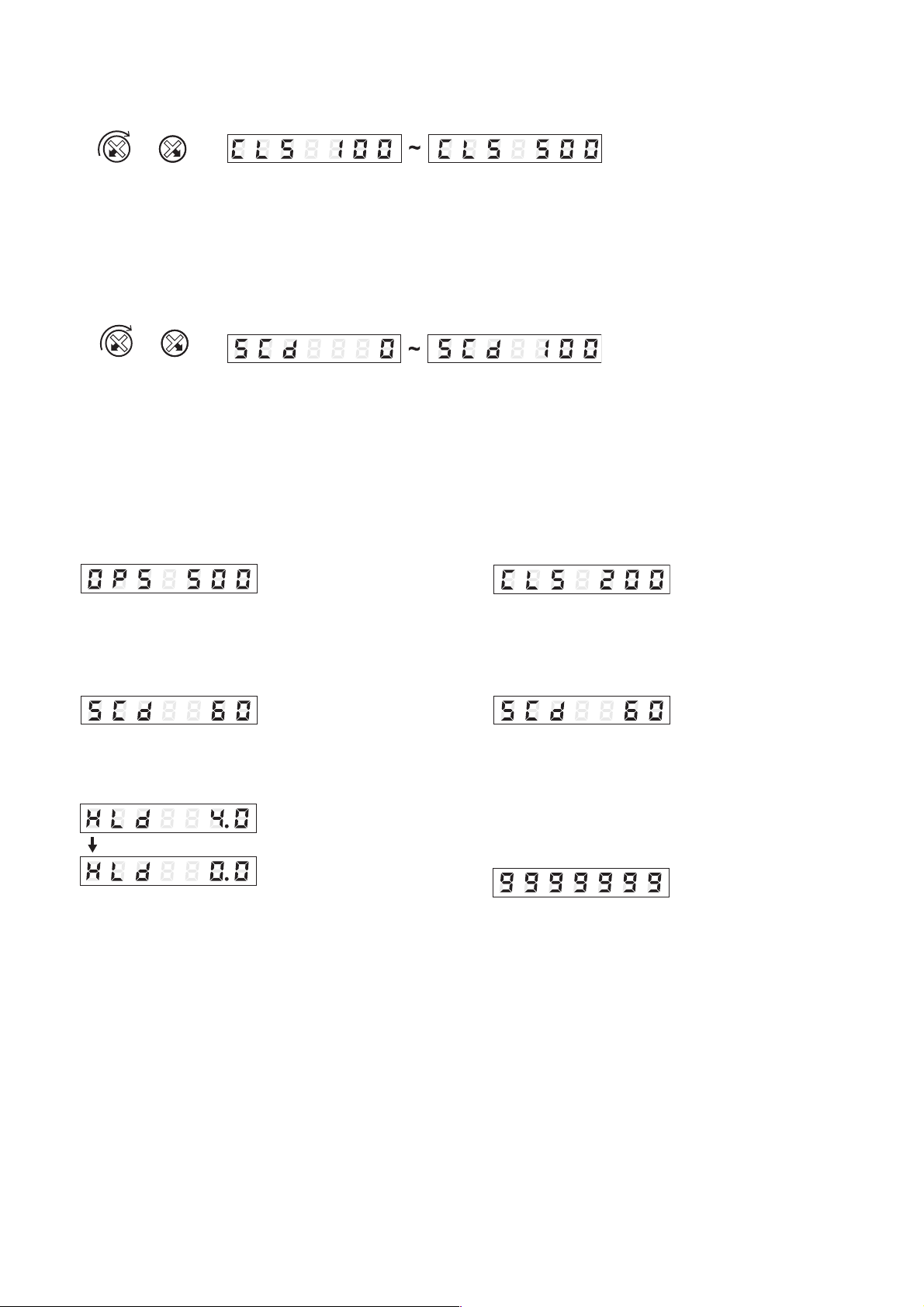

SW2

_

BN

BU

Receiver

MOTOR

M

Lock SW1

BN

BU

Emitter

Lock SW2

DOOR

CONTROLLER

PULLY

LOCK

SAFETY BEAM

CONTROLLER

Lock Mode

4*0.5mm2

15*0.5mm2

Activation Activation

SW 1

Hold Open

Opening Width

Adjust

Opening

Priority

INPUTS

8*0.5 mm2

3*1mm2

11*0.5mm2

2*0.5mm2

• Slides up and down to adjust height

of belt or to separate from drive bar

• Loosen front screws to adjust

Remove top

screws on belt

clamp bracket to

disconnect belt

Drive Bar

Height Adjusting Screws (2)

Remove these screws only if you

need to take door out of pocket.

F = Front. Must face you

(visible) when installing

POWER OUTLET

120/ 230VAC-3A

Connector Bracket

1RED +24VAC

2BLACK −

3WHITE SWITCH

4BLUE

5RED LOCK

6BLACK

1 3

2 4

1 3

2 4

A B C D E

H G G G F

5 6 5 6

ACTIVATION

SWITCH

ACTIVATION

SWITCH

ACTIVATION SWITCH LOCK SWITCH

LOCK SWITCH LOCK SWITCH

ACCESS

PANEL SIDE ADVANCED

FEATURES SOCKET

(See Separate Instructions)

OTHER

SIDE

M005 M007