2. Cleaning the ARROW:

Once any unused line marking liquid has been removed from the tank, the ARROW can now be

thoroughly and easily cleaned. The tank is manufactured from rotationally moulded polyethylene

plastic and therefore makes the tank durable, lightweight and 100% corrosion free. This also

prevents line marking liquid from sticking to its surface and ensures that the tank is easier to clean

and to keep clean.

Using fresh, clean water, preferably through a hosepipe to generate natural pressure, the tank should

be thoroughly washed down inside and out and any residue line marking liquid removed, ensuring

that extra attention is given to the internal aluminium and centre transfer wheels. This can be

achieved with the tank in the upright position, so that any waste water immediately runs out of the

tank. This should be undertaken in a suitable place and care must be observed to ensure no residue

of line marking liquid or washings are allowed to enter a surface water drain.

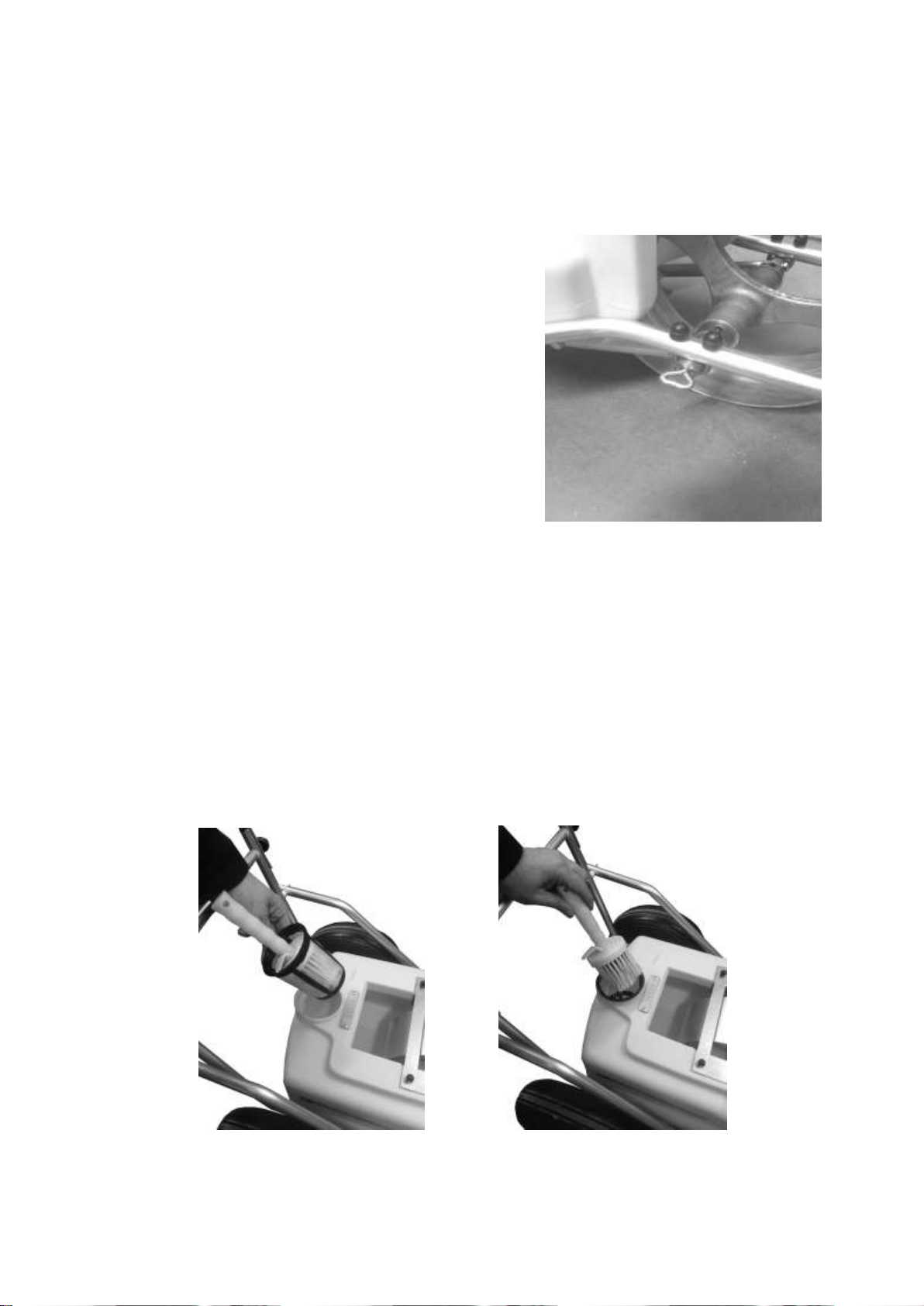

The chassis can be cleaned down at the same time, to ensure that the external aluminium transfer

wheel and scraper are thoroughly cleaned at the same time. The chassis is manufactured from triple

coated steel and is highly resistant to corrosion. The use of water to clean the chassis will not be

detrimental to the machine.

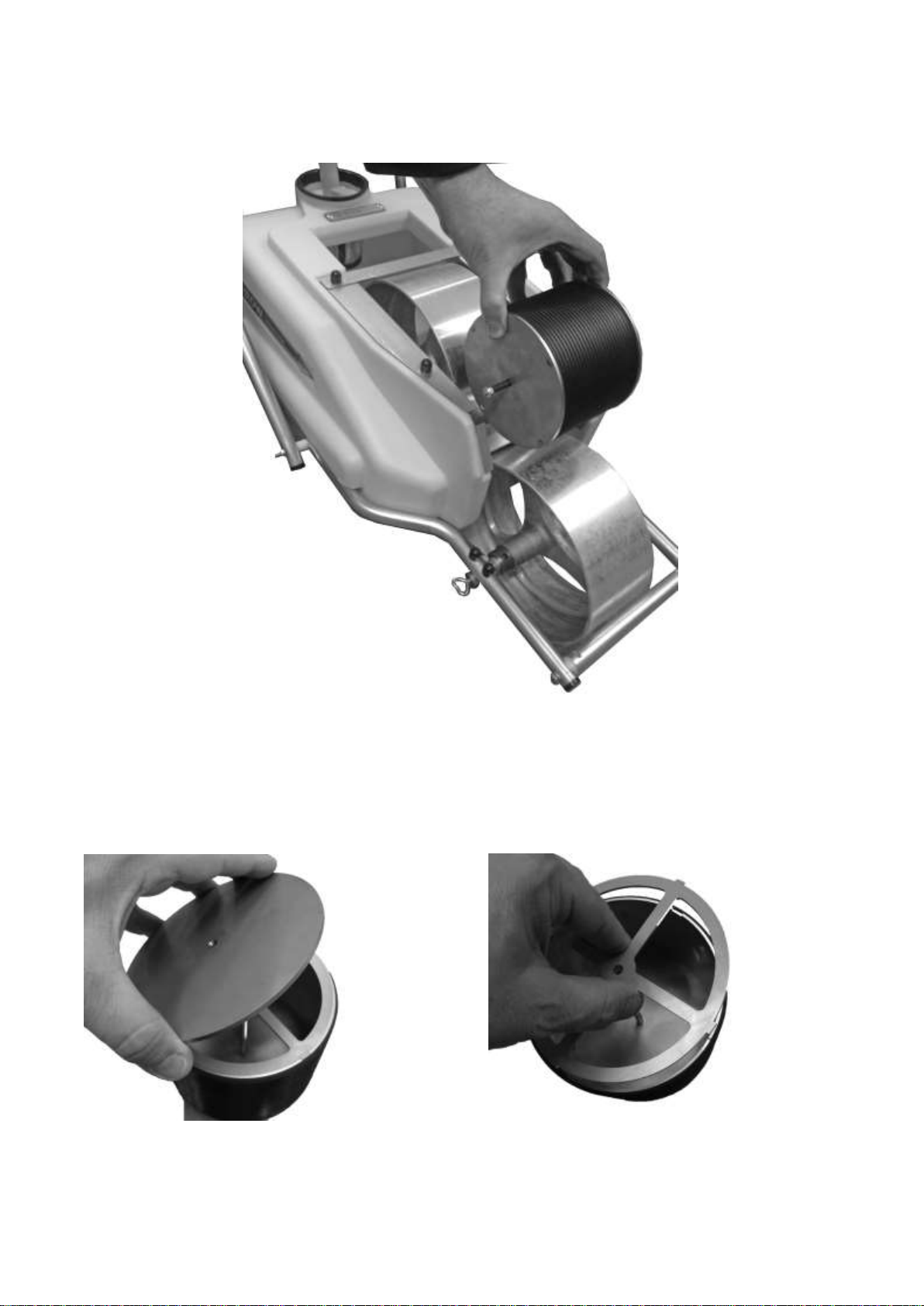

The tank can be completely removed as described above. This enables the operator to take the tank

to a suitable area for thorough cleaning, without the need to transport the entire machine to the

cleaning facility. The drip brush can be cleaned alongside the whole process and using it to wipe

around the tank will aid the cleaning of both the brush and the tank of the machine.

The centre axle for the internal aluminium wheel is greased during the manufacturing process. This

helps to prevent any line marking liquid sticking between the axle and the aluminium wheel. It is

recommended that fresh grease be applied to the axle on a monthly basis, to continue to provide this

protection. It is not essential to remove the internal aluminium wheel. Simply smooth some grease

around the edges of the axle where the aluminium wheel sits and turn the aluminium wheel to spread

the grease into the axle itself.

See our demonstration videos at: www.supaturf.co.uk

click :- Demo videos

or scan the QR code below to go straight there