viZaar INVIZ MATRIX Supplement

Short Guide

www.vizaar.com

Revision: 2.59T

:: INVIZ®MATRIX

Preface :: Preface

A system constructed strictly according to the

practical demand of our customers and users. To

obtain maximum benefit and for a secure and

safe operation please read the manual before

starting up and using the instrument. When used

proper, this system will be offering you excellent

inspection capabilities over a long lifetime.

Having an INVIZ®SNK or INVIZ®Revolver 80 in-

spection camera at hand, you are going to ope-

rate the currently simplest and at the same time

most hard wearing camera technology for pipe

and vessel inspection and documentation. Expect

highest resolution, impressive colours, highest

light sensitivity, easy handling, digital image pro-

cessing and video memory as well as a smart text

generator option.

The INVIZ®SNK pan-tilt-zoom camera is being

desribed in this manual as well as the revolutio-

nary INVIZ®Revolver 80 camera head with its two

cameras inside - being operated by excactly the

same handheld controller, main cable system

and video processor. Even plenty accessories will

be the same – and finally of course the working

environment in any power- or chemical plants

plus refineries.

In order to obtain the economic advantages of

your system even in the long run, you ought to

read and follow the following advice, tips and

warnings carefully. The observance of these in-

structions serve the purpose of secure working

with the system as well as your own safety.

All tips, code of behaviour, suggestions for mea-

sures to be undertaken, advice, warnings and in-

structions are exclusively valid for the operation

of INVIZ®MATRIX and not for devices by other

manufacturers, for which please refer to the ex-

ternal operating instructions and warnings.

For questions, which have not been answered by

this instructions manual, your dealer and/or the

manufacturer are gladly available for advice.

Kindly contact us even if you have suggestions for

the improvement of this manual or the product.

For contact details please consult the last page.

Thanks for choosing a viZaar®product for your

inspection service

Congratulation to your new

INVIZ®MATRIX system!

www.vizaar.com

Preface :: Preface

Your INVIZ MATRIX system can be used as

A) Stand alone video conversion and digital do-

cumentation system

B) Platform for many RVI solutions.

www.vizaar.com

Touch screen, digital high

resolution, image display,

joystick, camera control,

text and data control

Future

inspection

equipment

VISI B X

and VISI probe

systems

Existing

analogue video

documentation

Existing

inspection

equipment

assets

Multible

I/

Defined processes

INVIZ®RVI

product range

Sort

data

Add

graphic,

text,

audio

Generate digital

video sequences

or images

Data

storage

system

Preface :: Preface

www.vizaar.com

:: INVIZ®SNK pan-tilt-zoom camera

:: INVIZ®Revolver 80 dual view camera with endless rotation

:: INVIZ®Pipe camera

REMOTE VISUAL INSPECTION OF VESSELS, STORAGE TANKS & BIG VOLUMES

:: INVIZ®DE 2.4mm

:: VISIO probe videoendoscope range 3.7mm, 4mm, 6mm, 8.5mm

:: VISIO BOX

REMOTE VISUAL INSPECTION OF SMALL SPACES

:: INVIZ®BI push camera

:: INVIZ®Pipe camera

REMOTE VISUAL INSPECTION OF MEDIUM VOLUMES

Analogue to digital conversion any format (PAL/NTSC) to digital video in MPE or AVI, and still images

in JPE or BMP.

CONVERT AND EDIT EXISTING ANALOGUE INSPECTION DATA SUCH AS VIDEO RECORDS

INVIZ®SNK pan & tilt, INVIZ®Revolver 80 dual view and endless revolving camera, INVIZ®BI push

camera system, INVIZ®tube inspector will perfectly be controlled by the touch screen and Joystick of

the unit while you get the unbeatable image and software performance known and transfered into the

MATRIX from the industry leading INVIZ®VUMAN®Videoendscope concept.

CONTROL AND UTILIZE AN INVIZ®INSPECTION CAMERA

Connect all conventional rigid and flexible fiberscopes using a video adapter. Utilize the image analy-

sis, documentation and storage performance of your INVIZ®MATRIX.

COMPLETE THE FULL RANGE OF INSPECTION EQUIPMENT WORKING FROM

AND SAVING INTO ONE MATRIX S STEM

Any other standard signal providing camera oder videoscope type product. Convert instant to digital

and benefit of the high resolution digital image and storage capabilities. Store all data loos free at one

space.

CONNECT DIRECTL AN OF OUR OTHER EXISTING VIDEO INSPECTION EQUIPMENT

:: INVIZ®Revolver 80 dual view camera with endless rotation

:: INVIZ®Pipe camera

REMOTE VISUAL INSPECTION OF BIG SIZED TUBES, VESSELS & OTHER VOLUMES

Add graphic, text and audio to your digital inspection data. Sort your images and videos in smart,

individual archives on just one system.

EDIT OUR DIGITAL INSPECTION DATA

Easy to use, with smart data selection, security and back up functionality. Find plenty of space for your

valuable image and video data on the internal robust solid state drive, back up to or simply save di-

rectly onto any of your external USB device simplifying your workflow, protecting and archiving your

valuable inspection results.

STORE OUR INSPECTION DATA ON THE ROBUST SSD OR VIA USB SLOT

Warning

Before the initial operation, this instructions

manual must be completely read and under-

stood by the user in order to prevent damage

and danger to life and property through the ope-

ration of the system (the device). The operation

of the device without the understanding of the

instructions manual is not allowed under any

circumstances. The device has been designed

exclusively for industrial applications to be used

exclusively by trained operators. It is absolutely

not suited for any medical or veterinary appli-

cation must never be operated by private users.

For a generally non-destructive operation of the

device, beside the safety of the personnel and

environment, an extensive knowledge of the de-

vice, the inspection technology, the safety in-

structions as well as the industrial field of

application are absolutely necessary!

The device must never be connected to electric

mains, if you have not understood this instruction

including safety warnings or even if you have not

understood individual sections or if you cannot

or do not wish to use the device in accordance

with the regulations.

viZaar®is not liable under any circumstances for

the consequences of misinterpretation or faulty

inspection results, which were achieved with the

device.

viZaar®shall not be liable under any circum-

stances for the loss of inspection data.

viZaar®shall not be liable under any circum-

stances if device parts are left behind in the in-

spected plant inadvertently.

www.vizaar.com

Compulsory instructions

for a safe start-up in ac-

cordance with regulati-

ons. Reading before the

initial operation is com-

pulsory!

WARNIN ! Not for medical use. Never use close to electrical facilities, or in hazardous or explosive environments. US or EUROPEAN patents may apply to all

INVIZ®products. Microsoft®, Windows®are either registered trademarks or trademarks of Microsoft Corporation in the United States and / or other countries.

© Copyright viZaar A . Subject to change. Illustrations may differ from the original. Subject to technical modifications and errors. All rights reserved.

For compulsory attention:

Warning against risk of injury or

loss of life to humans

Warning against significant risk of

damage to device and plant

Warning against fatal electric shock

Warning against life-threatening

explosion risk

Warning against life-threatening

fire risk

Warning

Warning

www.vizaar.com

The device must never be opened by the user at any place other than the lamp shaft. Life-threatening

electric currents are used or generated in the device; in particular, the device must never be used with

the housing open. The device must never be used when there are audibly loose parts inside the device.

The device must never be operated in moist environment (e.g. during precipitation) nor must

the control device or the operating pendant be submerged in water – there is a risk to life due

to electric currents!

Before start-up, the device must be acclimatized according to the ambient temperature.

This is valid in particular for cooled devices, wherein condensate accumulation during warm-up

can lead to destruction and damage due to electric spark over.

Never operate the device under conditions which do not comply with the operating conditions

or storage conditions described in the instructions manual!

The device must be checked annually by the manufacturer or an authorized third party for compliance

with the electrical safety instructions obligatory at the usage site and conformance with the as-deli-

vered condition of the device. The device must not be connected to the electric supply mains or other-

wise operated after the ascertainment of a defect or any deviation from the as-delivered condition.

This is valid, in particular, if the device has tumbled or fallen down or was exposed to a liquid.

The device must never be operated in operating environments which are vulnerable to explosion

or fire risk. The device is not equipped with safety devices or acceptance for operation in environ-

ments vulnerable to explosion or fire risk. An impermissible employment in environments suscep-

tible to explosion or fire leads unavoidably to a device-induced life-threatening explosion and to a fire

in the plant. The operator is obliged to check the plant for substances vulnerable to explosion or fire

before every new start-up of the device.

:: Warning

Never allow the device to be operated without supervision.

For safety reasons, it is necessary to switch-off the machine during pauses.

Never operate the device in radioactively contaminated environment!

Never expose the probe to ionizing radiation of any type!

The device must be transported exclusively in the transport case conceived for it by the

manufacturer. The device and the corresponding accessories must be packed in the transport

case only according to the instructions at hand.

For increasing your own safety against electric shocks with risk of injury or loss of life, the device

must always be connected and operated via a residual current circuit breaker system or an isolating

transformer. This can in any case be a compulsory condition depending upon the operating environ-

ment. For this, consult your responsible safety in-charge or the accident protection measures in

force in your respective country.

The use of too long power extension cords is life-threatening and forbidden (max. 25 m in case of

a supply line made of copper 3 x 1.5 mm2). Hereby, a life-threatening loss of the protective function

of the upstream safety element is possible. At the same time, voltage differences of the earth po-

tential as compared to the displaced reference point of electric output (bridged by a too long exten-

sion cord) could cause dangerous electric currents on contact with the device housing or

impermissibly high equalizing currents at the probe. In case of uncertainties, consult your on-site

electrical expert.

Exclusively the viZaar®accessory articles or spare parts described in this instructions manual may be

used in connection with the device. Always consult and follow the national and international

operations and safety regulations, Norms or regulatory authority’s advice.

Warning

www.vizaar.com

The device can be connected to the public electric supply mains through a ‘IEC-plug lead’ included

in the delivery or a ‘IEC-plug lead’ which complies with the local socket standards. The system ac-

cepts faultlessly all power supplies known worldwide with alternate currents of 96 VAC to 246 VAC

at 46 to 60 Hz. For safe operation, the device needs a reliable potential earth (PE) connection. In case

of doubt, an expert or the manufacturer must be consulted. The minimum output supplied by the

power connection can be derived from the device specifications contained in the instructions.

:: Warning

When operating the device outside the permissible operating conditions or with destruction caused

by usage which deviates from the instructions, non-compliance with the operating conditions or

through the usage of non-original spare parts or accessories as well as through impermissible ope-

ning of the device, the guarantee obligation or the guarantee commitment by the supplier or manu-

facturer lapses, in principle.

All components of the device must never be used in or in the vicinity of apparatus or equipment,

which are partly or fully energized by electric current of any type (e.g. transformers, motors, gene-

rators, switchboards etc.). The metallic housing oaf the camera conducts electricity and dangerous

currents are transmitted during every contact or even short-circuits can be triggered in the plant.

While connecting to the car’s voltage transformer, the base unit should be connected to

protective earth and the car body, even when a grounding plug is available.

Never connect a triploar plug to a bipolar socket! Avoid any contact between INVIZ®/ MATRIX

(and all working equipment) and components carrying electrical charges.

The system must be earthed properly in case of an electrified application in relationship to the

ground. If impossible, connect the system to the application or the ground (depending on which one

the user needs to touch). The user needs to be isolated against the current path of the earthed path.

In case an exchange of the lamp becomes necessary, one must proceed according to the procedure

in the instructions!

Never handle the main cable without working gloves! Considerable risk of getting injured! At the

same time, protective glasses must always be worn while operating the system.

The device must never be operated with damaged main cable. There is a danger that liquids might

penetrate the cable and thereby impair the functioning permanently or might cause a life threate-

ning electric shock to the operator! Even the use of a slightly damaged main cable can quickly lead

to the total destruction of the device due to the electric conductors laying inside. The operation of a

damaged main cable is impermissible within the area of jurisdiction of the European Union, since the

regulations on emission of electromagnetic radiation can no longer be adhered to with safety.

Never bring the device in contact with corrosive substances of any kind (acid or alkali).

Risk of damage and injury while manipulating the main cable and camera head. Never bring the

device in contact with solvent containing liquids! Risk of damage!

Never insert the device in plant parts the contents of which are unknown!

Always ensure that the respectively inspected metallic pipeline systems conform exclusively to a

homogenous earthing potential; electrically insulated transition points (e.g. sealings, plastic line

sections) can exhibit different electric earth voltage potentials depending upon the plant, which could

build up very high electric currents with sparking and substance burn-out in case of bridging through

the metallic, electrically conducting probe. Kindly consult your on-site expert in advance.

Content

www.vizaar.com

:: Content

1 Structure and start-up 01

1.1 Operating from the transport case 01

1.2 Accessories 05

1.3 Quick reference, initial setup and operation 06

1.4 Operating instructions / E-Reader 06

2 Tips, questions and answers 09

2.1 Tips for your operations with the INVIZ®MATRIX 09

2.2 Problems and system warnings 10

Short guide

Tips, questions and answers

This short guide helps you to work with the es-

sential features of the system and to find the full

operating instructions as E-Reader on your de-

vice. Additionally, please find the full operating

instructions on your USB device which is part of

the scope of delivery.

The E-Reader / full operating instructions are

available under the chapter „1.4.1 Save your ope-

rating instructions on a USB device“. You are able

to export the operating instructions as a PDF file

onto your USB device.

Read the complete operating instructions before

starting to work with the system!

www.vizaar.com

1 Structure and start-up 01

1.1 Operating from the transport case 01

1.1.1 Specifications 03

1.1.2 Control unit 04

1.3.1 Hardware setup 06

1.3.2 The control unit 06

1.3.3 User setup menu 07

1.2 Accessories 05

1.3 Quick reference, initial setup and operation 06

1.4.1 Save your operating instructions on a USB device 06

1.4 Operating instructions / E-Reader 06

1 Structure and start-up

1.1 perating from the transport case

Before opening the transport case, check the

container for possible transport damages.

Dimensions: (H) 540 x (W) 290 x (D) 400 mm; PE;

Weight empty: 9,26 kg

Weight incl. control unit (1,3 kg) and power supply

unit (2,2 kg): 10,7 kg.

01

www.vizaar.com

1Carry handle

2Turn the butterfly lock to open

the transport case

1.1a

1

2

:: 1.1 perating from the transport case

2

1.2a

1 Structure and start-up

Memorize the location of each part during removal

to proceed later in reverse sequence.

02

www.vizaar.com

1INVIZ®MATRIX

2Operating instructions

3Control unit

1Main power in

2Main power switch

3Audio in

4Audio out

512V DC out

6V A ext. Monitor out

7Remote control

8Reset button

9Connector for INVIZ®products

10 Video / S-Video In

11 Control unit locked to the base unit

12 USB 2.0 interface

1

2

3

11

12

12

10

2

1

3

:: 1.1 perating from the transport case

4

6

9

5

7

8

ATTENTI N! Connect the inspection camera

before starting the system!

1 Structure and start-up

1.1.1 Specifications

03

www.vizaar.com

:: 1.1 perating from the transport case

Dimensions in mm (W) 320 x (H) 30 x (D) 230

Weight 2,85 lbs / 1,3 kg

Mounting Base Unit: integrated recording |Portable: shoulder harness or magic-arm

LCD monitor 10,4“ LCD, contrast 600:1, 350 cd, transreflective LED illumination, 262.144 colors, viewing angle all directions +/- 90°

peration Resistive touch screen incl. five direct access buttons and joystick

Housing Carbon fibre design with all around elastomer bumper; power tube 1,6 meter (8,2 ft)

Features

Saving pictures and movies in low, medium and high resolution. Unlimited video recording. Full version file manager (create, copy, delete, rename files

and folders). Includes all image processing features (flip, mirror, rotate, 8x zoom, text editing, image filtering, contrast enhancement, brightness, full

screen mode and point marker feature). Full version text generator (additional 99 spaces for standard configurations, full color management for text and

background). Customizable color reference charts. Enables free positioning of picture settings. Up to 9 password-protected user accounts with indivi-

dual configurations. Multi-lingual user interface. Multi-lingual on-board manual, camera temperature display (SNK / Revolver 80)

LCD control unit

Dimensions in mm / inch (W) 540 / 21.26” x (H) 290 / 11.41” x (D) 400 / 15.74”

Weight 9,26 kg / 20,37 lbs

Environmental Specifications Operation temperature 5°F to +118°F (-15°C to +48°C) |Storage temperature -13°F to +150°F (-25° to +65°C) |Relative humidity max. 95%, non condensing

AC input 96 VAC – 256 VAC / 47Hz – 63Hz / max. 100 Watt (max. 220 Watt with optional INVIZ®SNK and INVIZ®Revolver 80 pack)

Housing Impact resistant HDPE/HWU plastic, aluminium profile with plastic edge protection

Video input PAL or NTSC composite and S-Video, auto detecting

Video output Analog V A PC to monitor connector (Resolution 1024 x 768), worldwide standard

Connectors and outlets USB 2.0, recording remote control, 12VDC / 500mA Aux-Out, optional Composite and S-Video output (PAL and NTSC)

System memory Up to 60 hours of high resolution MPE 4 video-recording or several thousand BMP and JP high quality images

INVIZ®MATRIX

1 Structure and start-up

04

www.vizaar.com

1.1.2 Control unit

1

3

5

6

47

9

1360° remote joystick* /

Pan and tilt control function when used in

combination with the INVIZ®SNK camera

head (and INVIZ®SNK / INVIZ®Revolver 80

docking bay) /

360° endless left / right / stop control

function when used in combination of the

INVIZ®Revolver 80 (and INVIZ®SNK /

INVIZ®Revolver 80 docking bay)

2Direct access button pad

A= 1) Toggle between standard / setup.

2) Switch to setup from every menu

(except setup).

B= Capture single image

= Freeze / unfreeze

= Start / stop video recording

3Slight control button light control*/***

4Slight control RF Remote Focus**

(patented all distance Remote Focus)

5Battery status indication***

6Touch screen (image presentation

and system control keypad)

7Key rings for hooks of the shoulder strap

8Holding fixture for snap lock

(connects to base unit)

9Connector (cable to base unit connection)

:: 1.1 perating from the transport case

2

7

8

* Operational with INVIZ®camera systems.

** When combined with INVIZ SNK pan and tilt function, changes to light of the lamps.

*** Function only available when system is operated with battery docking bay.

1 Structure and start-up

05

www.vizaar.com

1.2 Accessories

Scope of delivery: Items 1-6.

Necessary scope for function 1-6 plus one optio-

nal pack (8/9/10). To work with INVIZ®SNK /

INVIZ®Revolver 80 item 11 is mandatery.

34

78

5 6

1 + 2

1INVIZ®MATRIX

2Control unit

3Power cord D, UK or US

4Umbilical cord for control unit

5Shoulder strap

6Head set

7Short guide

8USB device with full operation instructions

8Optional docking bay case

9Optional battery

9.1 Charging unit

9.2 Power cord D, UK or US

10 Optional power pack

11 Optional INVIZ®SNK / INVIZ®Revolver 80

pack

12 Optional camera head case

13 Optional INVIZ®SNK pant-tilt-zoom camera

14 Optional INVIZ®Revolver 80 endless

rotation camera

15 Centring ring small

16 Accessory soft pack

16.1 INVIZ®SNK / INVIZ®Revolver 80

main cable

16.2 Centering trolly (small + large)

17 Pushing aid (only INVIZ®Revolver 80)

18 Push poles (only INVIZ®SNK)

19 Push pole adapter

20 Tripod (only INVIZ®SNK)

Connection and operation of the control units

software and functions is represented in the fol-

lowing chapters.

Some accessories are not included in delivery

and must be purchased additionally. Therefore,

please contact your local sales representative.

:: 1.2 Accessories

8

12

16

17 18 19 20

9

10

11

13

16.1

14 15

9.1 9.2

16.2

1 Structure and start-up

1.3 Quick reference, initial setup

and operation

This part will allow you a quick first setup. Your

INVIZ®MATRIX offers many valuable and useful

options. For safety and to have full benefit of your

system please ensure to read and explore the

detailed descriptions and the complete manual

in chapter 2 to 6.

1.3.1 Hardware setup

Power the system by connecting the power cord

and/or attaching the charged battery pack. Turn

the main switch ON. The system will boot up.

1Insert power, optional battery pack or INVIZ®

SNK / INVIZ®Revolver 80 pack

3Dock the power supply unit / optional battery pack

4Fix the pack by mounting the pins back into

its position.

1.3.2 The control unit

3Release control unit (lift latch)

The control unit with the integrated touch screen

can be operated in three different ways.

4Connect umbilical cord control unit to base unit

Possible ways to use the control unit

5a n the system

(Pull up the control unit until the mounting

locks in the fixture.

5b Using the shoulder strap

(Take the harness and connect the hooks to the

key rings provided on the key rings (see page 04).

For setup 5b please refer to chapter „1.1.2 Con-

trol unit“.

06

www.vizaar.com

3

4

5a

5c

:: 1.3 Quick reference, initial setup and operation

2

4

1

3

ATTENTI N! Mind the connectors while

docking the battery pack!

1

25a

5a

1

2

1.3.2a

5a

1 Structure and start-up

1.3.3 User setup menu

There are three different start up screens de-

pending on wether using the INVIZ®SNK / INVIZ®

Revolver 80 power pack or standard / battery

pack.

A) Starting with the INVIZ®MATRIX

The first screen setting will ask you to choose a

user setting. For a fast and first start choose

default user.

Additionally up to nine codes secured individual

user configurations can be choosen. (See page 09)

Enter by touching the forward arrow on the

screen

A first camera image will show up on the screen.

By setting the white light control slide bar on the

control unit to maximum the light control is in au-

tomatic (only INVIZ®products) (see page 04).

The red slide bar offers the patented Remote

Focus (see page 04). Sliding up or down will bring

your image into perfect focus.

B) Starting with the INVIZ®SNK /

INVIZ®Revolver 80 pack

The first screen setting will ask you to choose a

user setting. For a fast and first start choose

default user.

Additionally up to nine codes secured individual

user configurations can be choosen. (See page 09)

Enter by touching the forward arrow on the screen

A first camera image will show up on the screen.

For further information on the additional features

and functions when used with the INVIZ®SNK /

INVIZ®Revolver 80 operation menue, please refer to

„3.2.3 INVIZ®SNK / INVIZ®Revolver 80 operation

menue“ on page 30 (only full operation instructions).

07

www.vizaar.com

:: 1.3 Quick reference, initial setup and operation

1 Structure and start-up :: 1.3 Quick reference, initial setup and operation

Shutting down the system

Please follow further advice to ensure a safe

shutdown of the system:

1. Touch the OFF symbol on your touch screen

(the OFF symbol finds itself on the left bottom

of every menue).

2. After pushing OFF, a menue occurs on the

touch screen. Now select if you want to turn

off your system of return to operation.

If you want to turn off your system through the

setup menue, go to „System Backup and Shut-

down“ and push „System Power Off“.

After pushing „System Power Off“, please wait

for the shutdown screen to occur and turn off

your system with the main switch.

For turning off the system in any another

menue, follow further instructions.

1. Touch the OFF symbol on your touch screen

(the OFF symbol finds itself on the left bottom

of every menue).

2. After pushing OFF, a menue occurs on the

touch screen. Now select if you want to turn

off your system of return to operation.

For further shutdown instructions and backup in-

stallation after system breakdowns please refer

to „3.7 System backup and shutdown“ on page

36 (only in full operation instructions).

1.4 perating instructions / E-Reader

1.4.1 Save your operating instructions on

a USB device

To save your operating instructions on a USB de-

vice, plug a USB devicde to the base unit. If con-

nected correctly, the USB symbol will appear.

Press

To confirm the process and remove the USB device,

please press

The button starts to light yellow. When the but-

ton dissapears after a few seconds, the process

was successful. In case the buttons stays active,

please repeat the process.

08

www.vizaar.com

ATTENTI N! Always shut down the system

as shown in the operating instructions.

Non-observance of the instruction may

cause system failures and/or data loss!

N TE! When the symbol lights green the co-

pying was successful. When the symbol lights

red three times, please repeat the process.

ATTENTI N! Do not remove the USB device

after the process without completing the next

step shown in this operating instructions!

www.vizaar.com

2 Tips, questions and solutions 09

2.1 Tips for your operations with the INVIZ®MATRIX 09

2.2 Problems and system warnings 10

2.1.1 After the initial start-up 09

2.1.2 eneral tips 09

2 Tips, questions and solutions :: 2.1 Tips for your operations with the INVIZ®MATRIX

2.1 Tips for your operations with the

INVIZ®MATRIX

2.1.1 After the initial start-up

After the initial startup of the INVIZ®system, the

following points may be noticed by you:

:: The image is out of focus. The focal range

was perhaps not set for current setting and

the observation of the environment. Use the

Remote Focus slide knob on your control

panel to get your system into focus.

:: The image appears slightly violet; the correct

image shooting under the influence of

daylight is not foreseen; the infra-red portion,

which is invisible to the human eye, is often

no longer filtered in endoscopic cameras for

reasons of light sensitivity, since an IR filter

is already integrated in the cold light sources.

This is no cause for worry.

2.1.2 General tips

In the following, we have collected a few general

tips, which can help you to economically and fast

achieve good inspection results. The points do not

concern your work safety,but exclusively serve

the purpose of communicating general technical

knowledge.

Before introducing the probe into a cavity or a

pipeline, it must always be ensured:

:: That the application is free of acids, alkali,

oils and solvents. All non ph-neutral liquid

media may destroy different parts of the probe.

:: That the application is not impurified with

liquids, the viscosity of which lies below that

of water (e.g. glysantine). In such case, a

suitable special camera head with sealed fix

focus optic is needed.

:: That no elements in the application can be

activated, e.g. remote control valves, turbine

rotors, agitators etc.

:: For achieving meaningful inspection results,

the application ought to be cleaned in

advance, as long as depositions need not be

documented. In case of unclean plants, the

optic or the light out of the camera is dirtied

fast.

:: The farther you insert a probe, the greater is

the danger that it might get stuck. In

principle, an endoscopic probe can be more

easily inserted than extracted, as far as

straight, narrow and steeples pipelines are

not being inspected. In perimeters (e.g.

heating pipes at apparatus and reactors) this

can lead to self-obstruction – similar to a

lasso. Do not lose your nerves in such a

case- there are often different methods of

disengaging the probe without opening the

plant or destroying the probe. The risk of

getting stuck on steps is increased with the

employment of centring tools. In principle,

never use force while releasing! The

manufacturer offers a foreign parts retrieving

service. In order to limit the long-time action

of unknown substances, the probe ought to

be cleaned after use.

:: Mount your equipment basically in such a

manner, that it stands absolutely securely.

Fundamentally, the probe does not possess

the constructive characteristics of stopping a

free fall of the control device without

breaking. Through an insecure mounting,

you are principally seriously endangering

persons, perhaps working on levels beneath

you. At the same time, strong jolts are

resented by a rotating arc lamp, besides

shortening its lifetime, possibly accompanied

by total failure.

Further questions in respect of the selection of

the device technology or settings, all viZaar®

co-workers and dealers are gladly available to

you for help.

09

www.vizaar.com

2 Tips, questions and solutions :: 2.2 Problems and system warnings

2.2 Problems and system warnings

The system doesn’t start up.

A) Check the main power connection cable is

well connected at both ends and power is

available.

B) Optional battery power (Check that the

battery pack is fully charged (see battery

power indicator on your control unit see

description page 26).

C) Check that the battery is well connected.

D) Check the systems function using

main power.

E) Check that the main power switch (2) is

turned ON (see page 02).

The system starts up but the touch screen

doesn’t respond.

A) Due to Windows®typical timing issues the

handshake between base unit and control

unit might not be established. Disconnect

and reconnect (hot plug) the connection to

restart and establish the handshake.

(See picture 4,system setup page 06).

B) Is the cable connection between base unit

and control unit established and both

connectors solid connected?

The image is flipped, rotated or mirrored

Touch to reset all image operations.

(See page 13).

Smearing turn of image manipulation

Set back all image configuration see page 13.

The system doesn’t respond anymore

If your system doesn’t respond turn the main

switch off and start it again by turning the main

switch on.

The system shows an error message

after booting

If your system shows an error message after

booting please follow the instructions on your

touch screen.

The software version on the right bottom

of the screen is changing its color / blin-

king

If your software version on the right bottom of the

screen is changing its color into orange, the sy-

stem is restoring system files. With the next start

of your system, the color will change back to

white.

If your software version on the right bottom of the

screen is blinking red by the next start, there is a

hardware failure. We recommend to contact your

local sales representative.

The background is flashing red and an

error message is occuring / the back-

ground is flashing red

If the saving of images failed, the background be-

gins to flash red and an error message occures.

Please repeat the saving procedure.

If the saving of images during the filming of a video

failed, the background begins to flash red. Please

repeat the procedure.

10

www.vizaar.com

WARNING! Don’t turn off the system while

performing the restart!

Table of contents

Popular Control System manuals by other brands

Techno CNC Systems

Techno CNC Systems Titan Series manual

OutBack Power Technologies

OutBack Power Technologies MATE3s Programming guide

ILMOR

ILMOR ONE-TOUCH owner's manual

SKF

SKF Multilog On-Line System IMx-M user manual

Norac

Norac UC4 Total Control installation manual

Opencockpits

Opencockpits A320 Sidestick PRO Assembly manual

Mitsubishi Electric

Mitsubishi Electric PAC-WHS01WF-E Technician manual

Siemens

Siemens SIMATIC HMI KTP400 Basic manual

Taylor Made Environmental

Taylor Made Environmental Cruisair SMX II Installation & operation

Politec

Politec SANDOR WS SMA INSTALLATION AND MOUNTING MANUAL

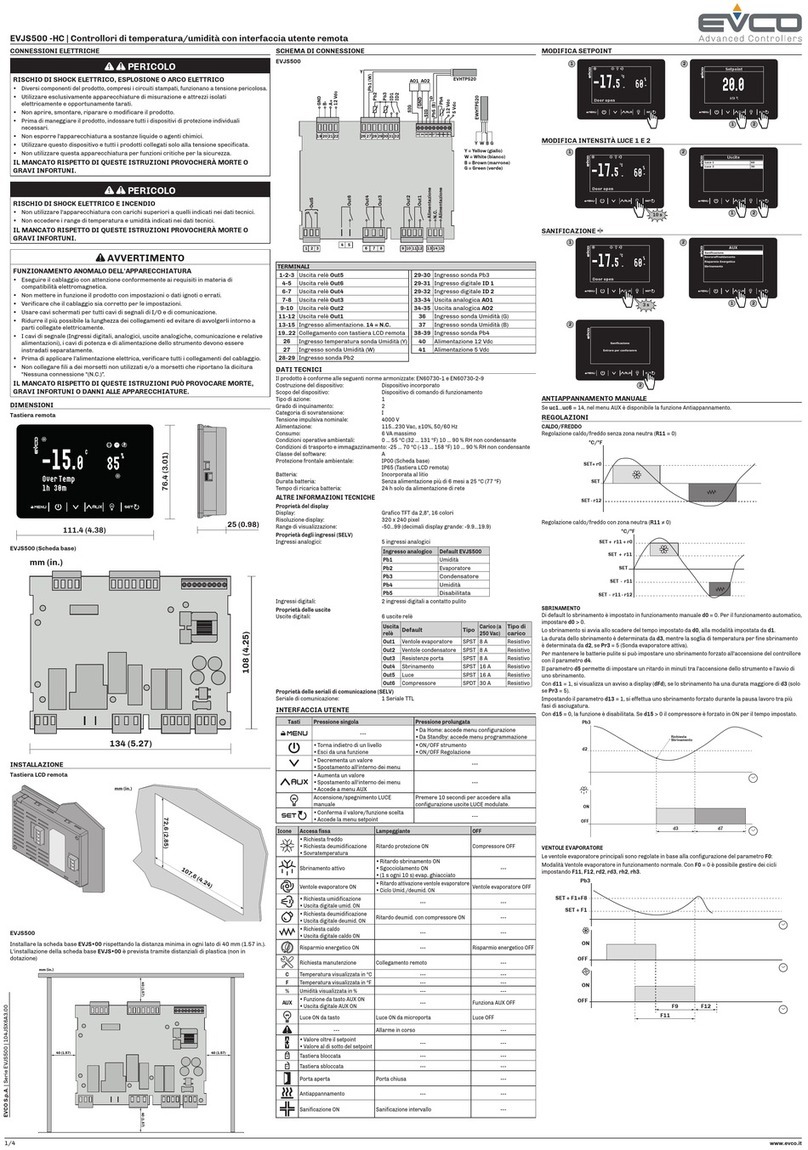

Evco

Evco EVJS500 quick start guide

RuiDa

RuiDa KT332N user manual