Step 18.1 Consult your radio manual for instructions about

hooking up your receiver.

Step 18.2 Plan where you are going to put the receiver

with consideration for routing the antenna safely.

Step 18.3 Wrap the receiver securely in foam suitable for

RC equipment and wrap the foam insulated receiver in a

plastic bag or cling wrap.

Step 18.4 Install your receiver near the aft end of the fuse-

lage as shown in 18B.

INSTALLING THE RECEIVER BATTERY

STAGE

17

Step 17.1 Consult your radio manual for instructions about

hooking up your receiver battery, receiver and switch har-

ness.

Step 17.2 Wrap the battery pack securely in foam suitable

for RC equipment and wrap the foam insulated pack in a

plastic bag or cling wrap. Position the battery pack as

shown in 18B.

Step 17.3 Thread the battery pack connector forward in

preparation for connecting to your switch harness.

Step 17.4 Connect the battery pack connector to your

switch harness according to your radio manual.

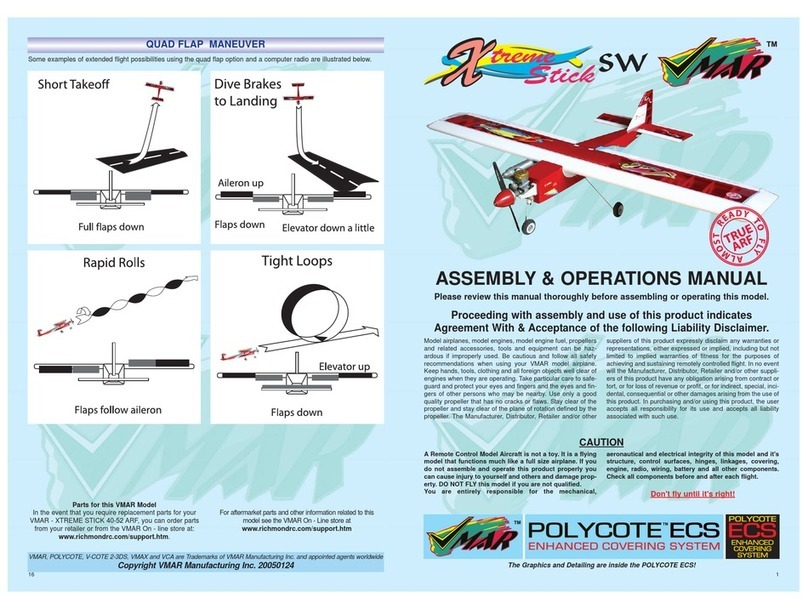

With the throttle control arm connected to the engine throttle arm ensure that the throttle servo moves the throttle barrel

from nearly closed to fully open.

Adjust the deflection of the control surfaces to match the

specifications on page 11. You can reduce the amount of

throw by doing either or both of the following:

- From the servo end, move the clevis or EZ connector to a

hole in the servo arm that is closer to the servo output shaft.

- From the control horn end, move the horn out further on

the threaded bolts. Always confirm that the horn is still

thoroughly engaged with the threaded bolt after you have

adjusted it.

8

CONNECTING THE THROTTLE CONTROL

STAGE

14

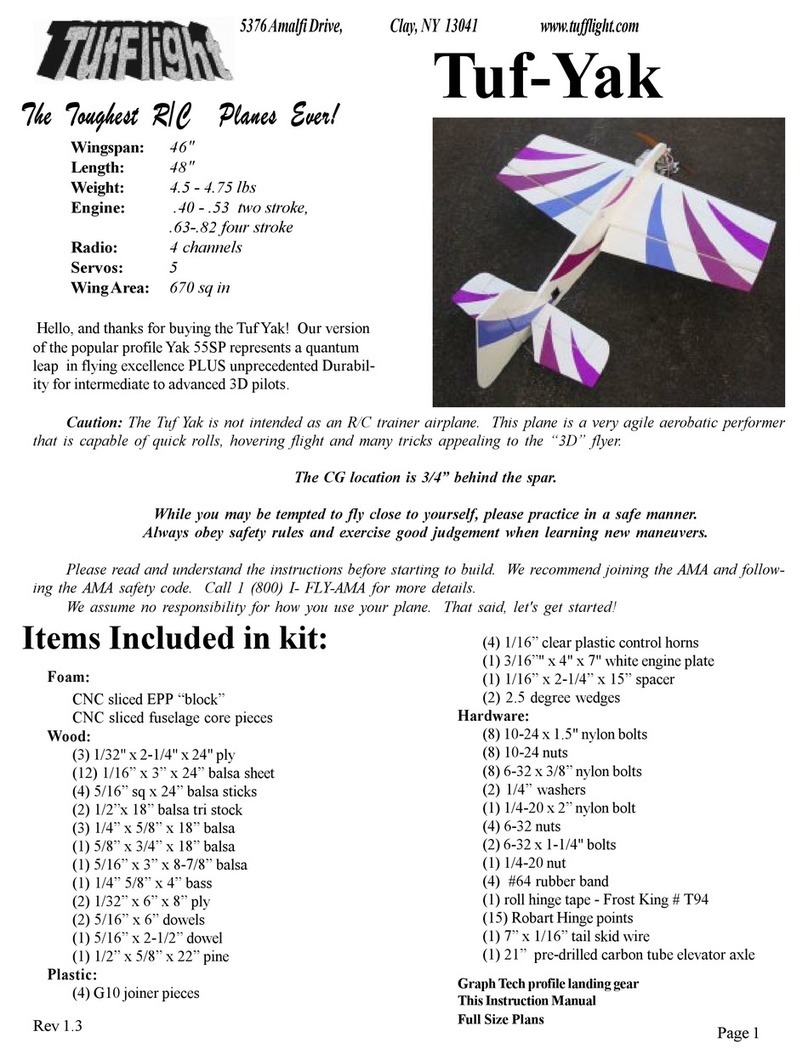

14B- The throttle servo controls the

engine throttle using the throttle con-

trol rod

14C- Completed engine with throttle

control connected and muffler

installed

14A- Throttle control rod connected to

the engine throttle arm

ADJUST CONTROL SURFACE THROW LIMITS

9

STAGE

15

FINAL RC SET-UP

STAGE 16

Step 16.1 Before starting the final set-up of the model,

switch on the radio and ensure that all trims are in their

neutral positions. Check that the aileron, elevator and rud-

der are centered. If any adjustments are needed, do these

by uncoupling the relevant clevis and turning it clockwise to

shorten the linkage or counter - clockwise to lengthen it.

Only when each control surface has been centered

mechanically in this way should you begin adjusting the

surface movement (or throw).

Step 16.2 Now confirm that the control surfaces are mov-

ing in the correct direction. Use the servo reversing switch-

es on your transmitter to reverse the direction of a servo if

necessary.

INSTALLING THE RECEIVER

STAGE

18

TAIL

Throttle

control rod

NOSE

TAIL NOSE

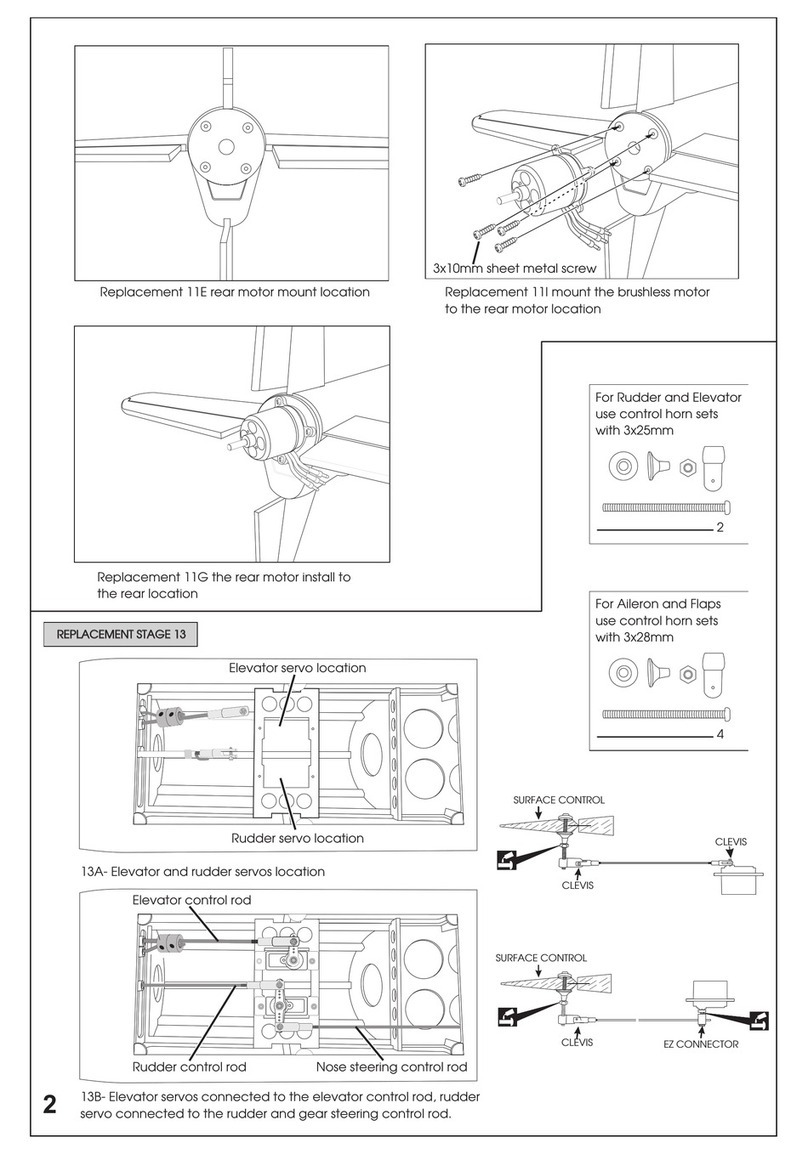

Step 13.1 Align the rudder with the vertical stabilizer and fuselage using a Bulldog paper clamp.

Step 13.2 With the rudder aligned straight with the fuselage. Turn over the fuselage and install the rudder control horn with

the EZ-connector installed. See 13C

Step 13.3 With the rudder aligned straight with the fuselage connect the rudder servo to the receiver and turn on your trans-

mitter. Ensure the rudder servo is centered at neutral.

Step 13.4 Connect the rudder control rod between the rudder servo arm and the rudder control horn EZ-connector. Tighten

the EZ-connector set screw firmly and ensure it is secure. Use medium thread locker (Blue). See 13D

Step 13.5 Connect the nose gear steering rod to the opposite side of the rudder servo arm. See 13D

13B- Align rudder with Bulldog paper clamp

13A- Rudder control horn assembly

13D- Rudder control rod installed between the rudder

servo and rudder control arm. Nose gear steering rod

connected to opposite side of servo arm

13C- Rudder control horn installed on the rudder control

rod

INSTALLING THE RUDDER

& NOSE WHEEL CONTROL SYSTEM

STAGE 13

TAIL NOSE

12B- Pre-installed elevator torque

rods & servo rails

12A- Elevator control rod assembly 12C- Control horns pre-installed on

the elevator torque rods

12D- Mount the servos on the pre-

installed servo rails 12E- For each servo, connect the con-

trol rod between the servo arm and

the control horn

12F- Elevator servos and control rods

installed

2-1/2 in. (65 mm)