512

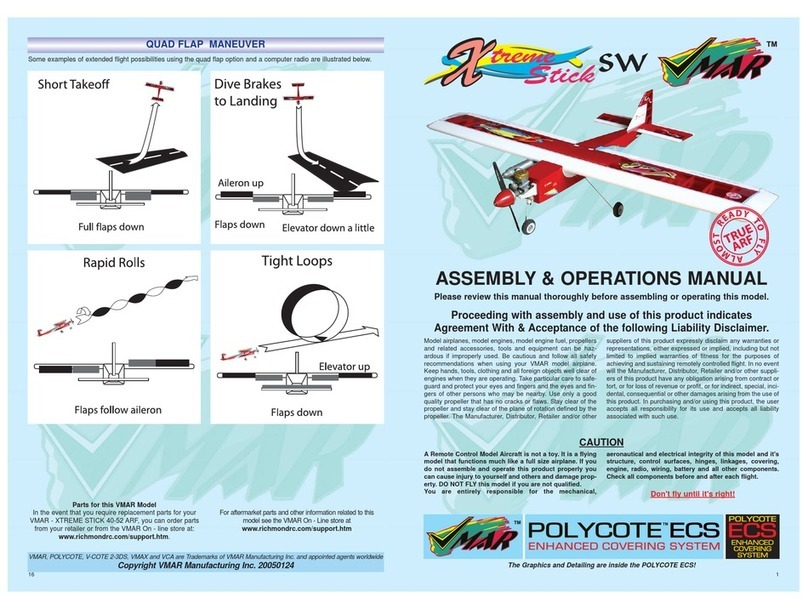

5J- Insert the horizontal stabilizer into

the slot.

Step 5.2 Mark the outline of the vertical stabilizer onto the horizontal stabilizer

using a non-permanent felt tip marker. See 5D & 5E..

Step 5.3 Now remove the horizontal stabilizer. Using a sharp knife & ruler CARE-

FULLY cut just 1/16 (1.5 mm) inside the marked lines (see 5F) and remove the

covering on both sides of the horizontal stabilizer (see 5G), , making sure you only

press hard enough to cut the covering, not the horizontal stabilizer.

USE CA TO FILL AND REPAIR ANY CUT MARKS IN THE WOOD.

Step 5.4 Apply sufficient 30 minute epoxy to the exposed wood areas on the top

and bottom of the horizontal stabilizer and into the slot of the vertical stabilizer. Use

only 30 minute epoxy. See 5H and 5I

Step 5.5 Insert the horizontal stabilizer in its slot in the vertical stabilizer and re-

check the alignment as in step 5.1. See 5M

Step 5.6 Clean off any excess epoxy with a rag or tissue before it cures. See 5K.

Step 5.7 After the epoxy has completely cured, install the rudder to the vertical

stablizer using the hinges supplied. Glue hinges into place using thin CA. See 5L.

WE RECOMMEND PINNING HINGES TO LOCK THE HINGES INTO PLACE.

5D- Mark the outline of the vertical

stabilizer onto the horizontal stabiliz-

er.

INSTALLING THE LANDING GEAR

STAGE

6

5E- Mark both sides of the vertical sta-

bilizer 5F- Carefully cut through the cover-

ing. Do NOT cut the wood

5H- Apply sufficient 30 minute epoxy

to the exposed wood areas on the top

and bottom of the horizontal stabiliz-

er.

90o

5K- Clean off any excess epoxy

with a rag or tissue before it cures. 5M- 90 degree angle between the

horizontal and vertical stabs

5L- Install the rudder using the

hinges supplied. Glue hinges with

thin CA.

5G- Remove the covering from

both sides.

The DHC 6 Twin Otter has a trike gear configuration using main landing gear and steerable nose gear.

CONFIRM RADIO OPERATION

STAGE

17

BALANCING THE AIRCRAFT

STAGE

18

Carefully review how your Electronic Speed Controls (ESC)

work. Most ESC's will not power up a motor until the throt-

tle has been reduced to zero. Avoid both props in case

either or both of the two motors suddenly start to turn.

Step 17.1 Consult your radio manual for instructions about

testing and operating your radio system.

Step 17.2 Pay particular attention to charging your batter-

ies and range testing your system before and after each

flight.

Step 17.3 Check that all controls are working correctly

before and after each flight.

FOR ELECTRIC POWER, YOU WILL NEED TO INSTALL

THE FUSE AND YOUR BATTERY TO TEST THE ESC'S

AND THE MOTORS.

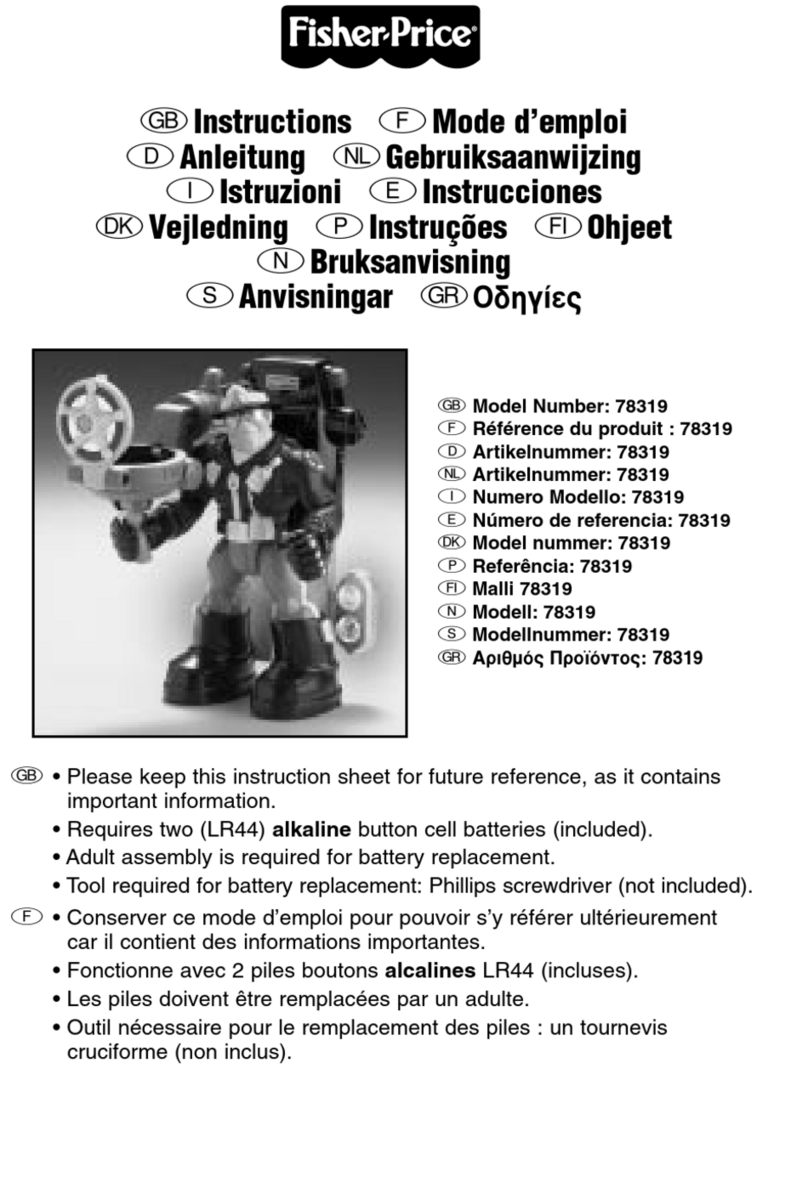

Step 18.1 The CG for your DHC6 Twin Otter is located at

2“ to 2-1/8" (50 - 55 mm) back from the leading edge of the

wing when the wing has been attached to the fuselage as

per illustration 19A.

Step 18.2 For the initial flight, the CG should be located at

2” (50mm) back from the leading edge of the wing when the

wing has been attached to the fuselage.

Step 18.3 The CG is measured with the motor, battery and

all other components installed.

Step 18.4 Set up the CG as it will be when you fly it.

Step 18.5 It is very important to have the CG correct. Flying

your model with the CG too far back will likely lead to loss

of control and a crash. If you discover that after you have

assembled your model and installed your radio, motor and

battery that the CG of your model is incorrect you must

bring the CG to the correct location by doing the following

BEFORE FLYING :

- Move the battery pack fore or aft

- Do not add weight to correct the CG. Move components &

especially your battery pack rather than add weight. Only

add weight as a measure of last resort.

CONFIRM MECHANICAL INTEGRITY

STAGE

19

Step 19.1 Once you have confirmed that the CG is correct,

you should do a thorough review of the entire model before

your first flight. Check everything twice! Every hook up,

every coupling, everything! Do it twice!!

Step 19.2 Before your first flight, have an experienced flyer

review your work. Do not fly your model until it has been

checked out by a third party who knows how to fly and how

to set up a model aircraft. Do not fly alone. Seek experi-

enced help.

Step19.3 Once you have completed your first flight, get in the

habit of checking your model over before and after each flight!

Don’t fly if you find something that is not right!

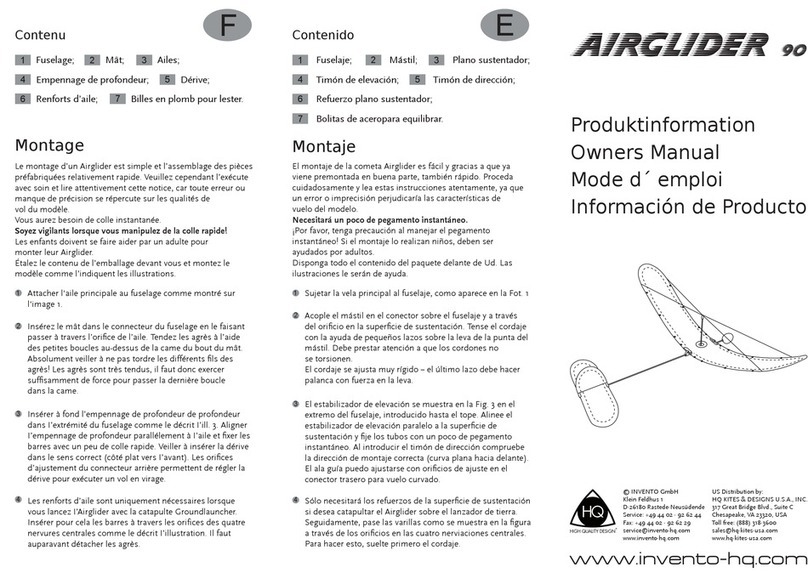

CONTROL SURFACE THROW SPECIFICATIONS:

The throws are measured at the widest part of the control

surface. Adjust the position of the pushrods at the control

and/or servo horns to control the amount of throw. You may

also use ATV's if you radio has them but the mechanical

linkages should still be set so that theATV's are near 100%

for best servo resolution.

Low rate High rate

ELEVATOR 1/6 “ (4mm) up 1/4” (6 mm) up

1/6 “ (4mm) down 1/4” (6 mm) down

AILERON 1/6” (4 mm) up 1/4” (6 mm) up

1/6” (4 mm) down 1/4” (6 mm) down

RUDDER 1/3 “ (8 mm) right 2/5” (10 mm) right

1/3 “ (8 mm) left 2/5” (10 mm) left

19A- CG location

55mm

50mm

5I- Apply sufficient 30 minute epoxy

into the slot of the vertical stabilizer.