8

This document is property of Vogel’s Products BV

Any distribution, reproduction, copying or publication of this document is prohibited.

ADJUSTMENT OF THE END STOPS

PLEASE READ CAREFULLY

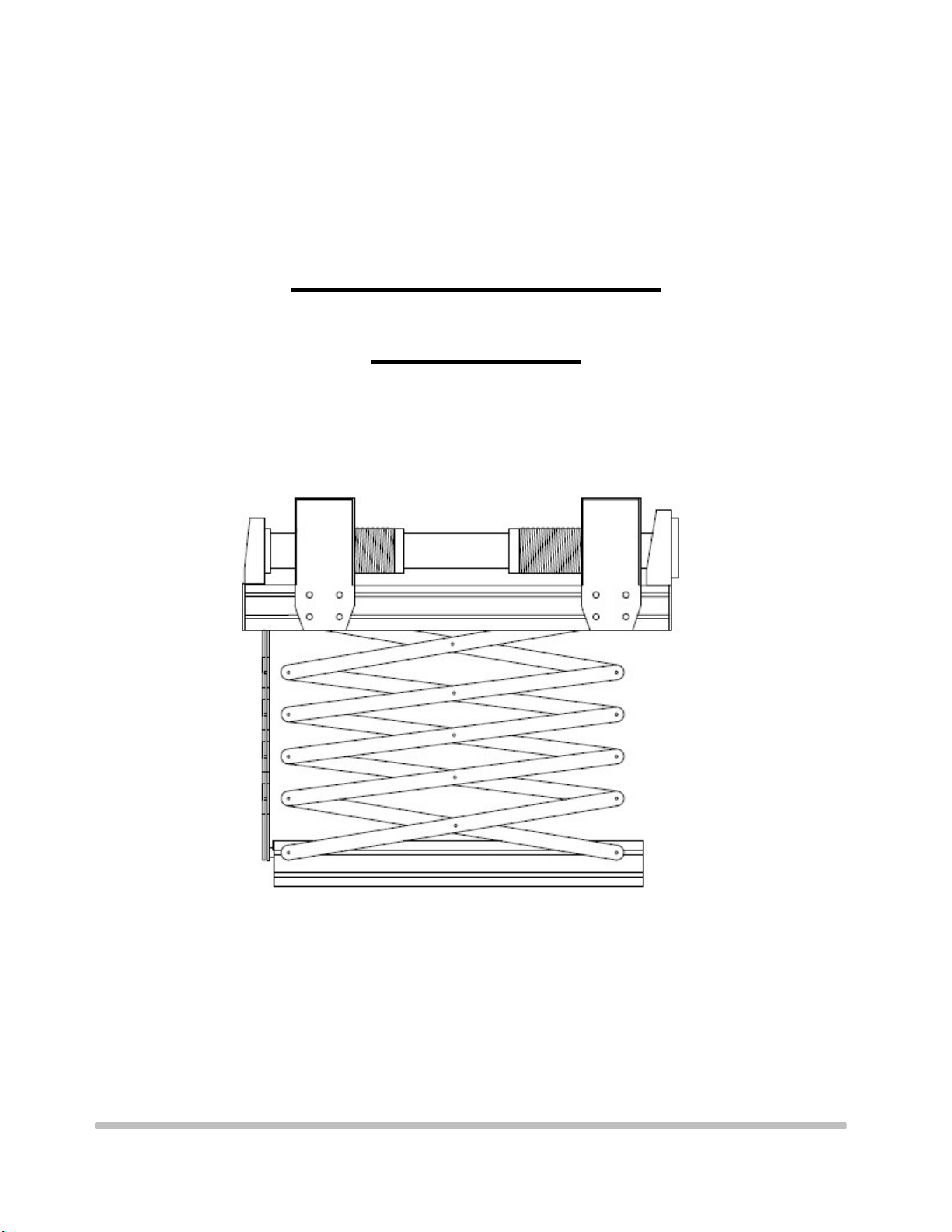

The PPL 2500 motorized lift is supplied with a remote control that allows to set three positions:

1. CLOSED LIFT: pre-set by the factory, in closed upper position. WARNING: in case the installer

needs to modify this end-stop, it is only allowed to lower the upper end-stop position. Do not

try to raise the upper end-stop because this will cause severe damages to the product and this

operation will invalidate the warranty.

2. PROJECTION MODE: intermediate stop position, not pre-set by the factory.

3. SERVICE MODE: lower end-stop position, pre-set by the factory at 2,5 mt. circa.

How to modify the end-stops:

A- SETTING OF THE LOWER END STOP (SERVICE MODE)

- Lower down the lift till half stroke, pressing the remote control button ▼ and stop it with

button ◼.

- Press the button ◼ (for 5 secs) till the motor swivels 2 times.

- Press again the button ◼ (for 5 sec) till the motor swivels 4 times.

- Press the button ▼ (for 5 sec) till the motor swivels 2 times.

- Press and hold the buttons ▼ or ▲ in order to the reach the desired position of the lift.

Warning: during this programming operation you have to keep the buttons ▼ or ▲ pressed in

order to reach the desired position.

- Once this position is reached, in order to memorize it press the button ◼ (for 5 sec) till the

motor swivels 3 times.

B- SETTING OF THE UPPER END-STOP

WARNING: in case the installer needs to modify this end-stop, it is ONLY allowed to lower the upper

end-stop position. Do not try to raise the upper end-stop because this will cause severe damages to

the product and this operation will invalidate the warranty.

- Lower down the lift till half stroke, pressing the remote control button ▼ and stop it with

button ◼.

- Press the button ◼ (for 5 secs) till the motor swivels 2 times.

- Press again the button ◼ (for 5 sec) till the motor swivels 4 times.

- Press the button ▲ (for 5 sec) till the motor swivels 2 times.

- Press and hold the buttons ▼ or ▲in order to the reach the desired position of the lift.

Warning: during this programming operation you have to keep the buttons ▼ or ▲ pressed in

order to reach the desired position.

- Once this position is reached, in order to memorize it press the button ◼ (for 5 sec) till the

motor swivels 3 times.