P18AL Service Manual

TABLE OF CONTENTS

ii

Startup Checklist............................................................................................................................................................3-11

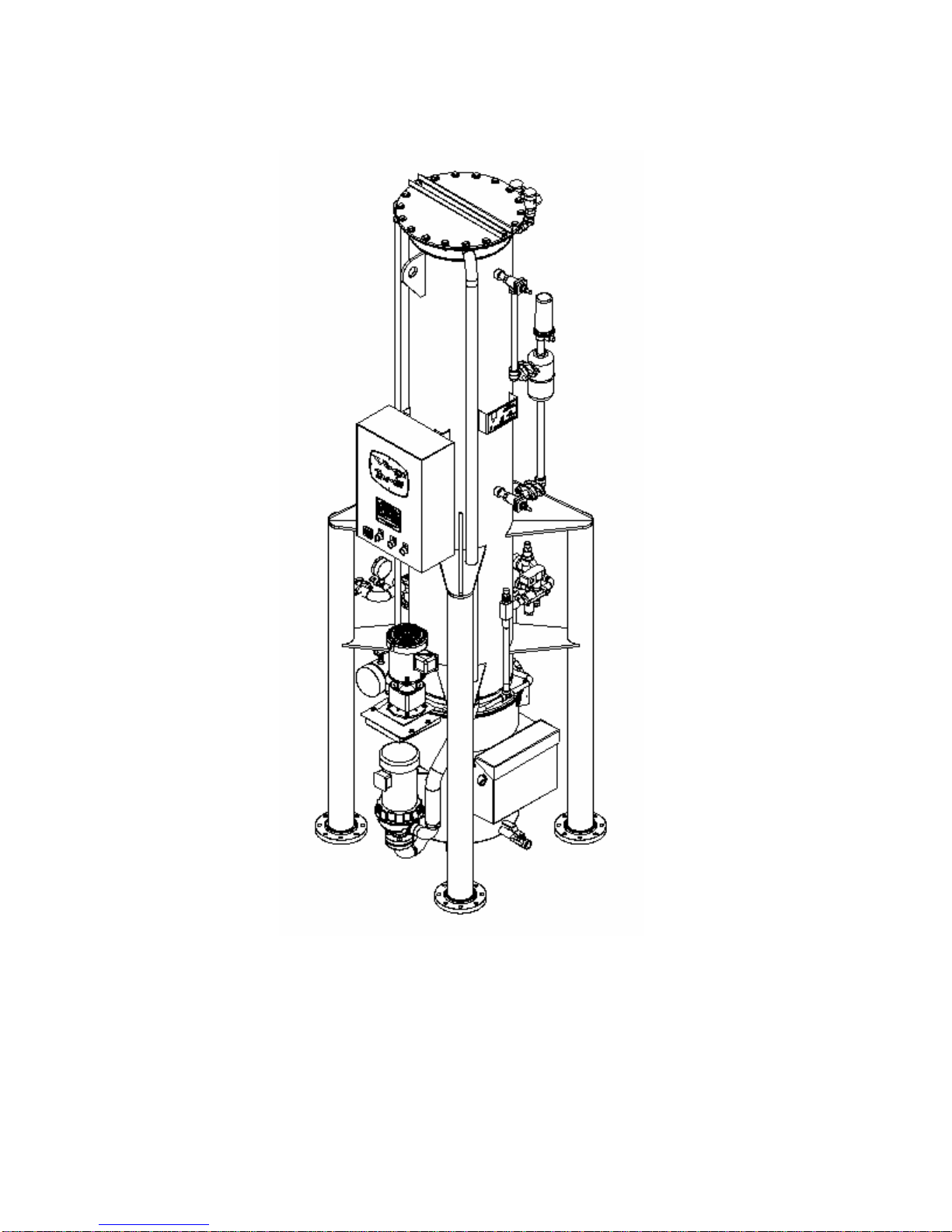

4. HOW YOUR TUBE-ICE MACHINE WORKS

Principle of Operation....................................................................................................................................................4-1

Freeze Period.................................................................................................................................................................4-2

Harvest Period ...............................................................................................................................................................4-2

Piping Nomenclature, Table 4-1....................................................................................................................................4-2

Water Cooled Piping Schematic, FIGURE 4-1..............................................................................................................4-3

Air-Cooled Piping Schematic, FIGURE 4-2..................................................................................................................4-4

5. START-UP AND OPERATION

Refrigeration System Review........................................................................................................................................5-1

Refrigerant Charge ........................................................................................................................................................5-2

Ammonia Specification By Grade, Table 5-1................................................................................................................5-2

Special Precautions........................................................................................................................................................5-2

Charging From Tank Truck (dedicated high side only).................................................................................................5-2

Charging From Cylinders (dedicated high side only)....................................................................................................5-3

Charging Operating Characteristics ..............................................................................................................................5-4

Start-up Procedure ........................................................................................................................................................5-5

Thaw Gas Regulating and Suction Gas Regulating Valve Adjustment ........................................................................5-6

Shut-down Procedure ....................................................................................................................................................5-6

Operating Tips ..............................................................................................................................................................5-7

6. ELECTRICAL CONTROLS & THEIR FUNCTIONS

General Information.......................................................................................................................................................6-1

Control Panel (Door Closed), FIGURE 6-1...................................................................................................................6-2

Control Panel Components and Part Numbers (External), TABLE 6-1.........................................................................6-2

Control Panel (Door Opened), FIGURE 6-2..................................................................................................................6-3

Control Panel Components and Part Numbers (Internal), TABLE 6-2..........................................................................6-3

Description of Control Panel Component Function, TABLE 6-3..................................................................................6-4

Electrical Schematic All Voltages 50-60 Hz, FIGURE 6-3...........................................................................................6-5

7. MAINTENANCE

Preventive Maintenance.................................................................................................................................................7-1

Preventive Maintenance Form.......................................................................................................................................7-2

Ice-Making Section........................................................................................................................................................7-3

Cleaning Procedure........................................................................................................................................................7-3

Water Distribution System ............................................................................................................................................7-4

Water Distributors, TABLE 7-1 ..............................................................................................................................7-4

Average Hole Size in Tube-Ice®, TABLE 7-2 ........................................................................................................7-4

Water Tank..............................................................................................................................................................7-4

Freezer Cover ..........................................................................................................................................................7-4

Other Maintenance Operations......................................................................................................................................7-5

Cutter Gear Reducer................................................................................................................................................7-5

Page No.

Oil Trap Draining ....................................................................................................................................................7-5