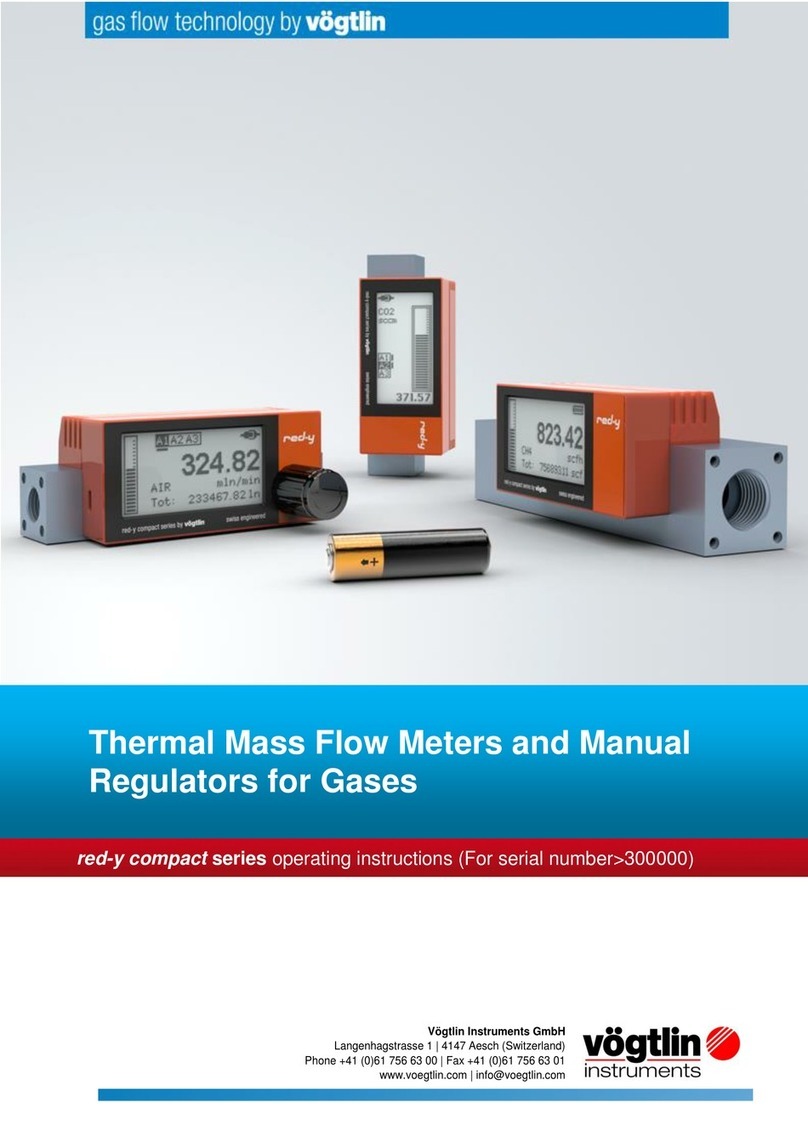

Vogtlin V-Flow Series User manual

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

02

Version: vflow_E4_7

For the latest information on our products, see our website at www.voegtlin.com

© 2010 Vögtlin Instruments AG, Switzerland

Operating instructions V-Flow Line

Variable area flowmeters Q-Flow

Variable area flowmeters V-100

High-precision control valves M-Flow

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

03

Contents

Introduction 5

Service and quality 5

Warranty 5

General instructions 6

Safety information 6

Using the manual 6

General information 7

Operating principle of the variable area flowmeter 7

Variable area flow meter type marking 8

High-precision control valve type marking 8

Technical data 9

Technical data Q-Flow 9

Materials Q-Flow 9

Setups Q-Flow 9

Technical data V-100 10

Materials V-100 10

Setups V-100 10

Technical data M-Flow 11

Materials M-Flow 11

Setups M-Flow 11

M-Flow valve operation options 12

Measuring ranges variable area flowmeters 13

Measuring ranges direct reading scales ln/h (Air) and l/h (Water) 13

Measuring ranges direct reading scales mln/min and ln/min (Air) 14

Measuring ranges mm-scale Q-Flow 14

Measuring ranges mm-scale V-100 14

CV-values high-precision control valves M-Flow 15

Installation and commissioning 16

General instructions 16

Installation instructions 18

Instructions for commissioning 18

Recommended connections 18

Panel mounting Q-Flow 19

Faceplate mounting V-100 20

Limit indicator 21

M-Flow Digiturn installation 24

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

04

Disassembly and maintenance 25

Important instructions 25

Disassembly variable area flowmeter Q-Flow 25

Disassembly variable area flowmeter V-100 26

Disassembly Digiturn M-Flow 27

Maintenance 28

Soiling 28

Cleaning 28

Return 28

Appendix 29

Dimensions Q-Flow 29

Dimensions V-100 30

Dimensions M-Flow 31

Type code Q-Flow 33

Type code V-100 34

Type code M-Flow 35

Contamination declaration 37

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

05

Introduction

We are glad that you have decided to use our variable area flow meters and high-precision control

valves. Our instruments will provide you with high-quality long-lived products.

This manual contains important information for commissioning and/or designing equipment. Please

contact your distribution partner if anything is not clear.

We are committed to the continual improvement of our products and documentation. Your

experience from everyday use can assist us with this. We welcome your comments and criticisms.

We have taken great care in compiling this manual. However, we cannot accept responsibility for

possible errors.

Service and quality

We are continually improving the quality and provision of our products and services. In the end,

whether the right product was selected only becomes apparent once the product is in use.

Therefore we make every effort not just to preach but also to live by top quality and service.

Warranty

The warranty for the products described in this manual is limited to defects in material and

workmanship. Warranty does in no case exceed product replacement free of charge. All claims are

null and void in the case of improper use:

Use outside the operating limits

Damage due to water hammer

Corrosion damage

Mechanical damage in general

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

06

General instructions

Check the package for external damage and contact your distribution partner if the instruments

have visible defects. Check that the delivery is complete and corresponds to the delivery note.

This product is a precision measuring instrument. We would like to point out that you should take

due care when choosing the installation site and following these suggestions and instructions.

Before installing, check that the specification on the type label matches your application.

Please read through these operating instructions carefully before commissioning. Incorrect

operation, errors in comprehension and the consequences of these can lead to breakage of the

instrument or risk of personal injury.

Commissioning and maintenance must be carried out by appropriately qualified personnel. Proper

use of the products is a necessary precondition for their smooth operation.

Safety information

The instruments must not be used outside the specified operating limits

(See also section Technical Data)

Incorrect operation can lead to breakage of the instrument or risk of personal injury.

When using toxic media it is strongly advised not to use glass cylinder measuring instruments:

cylinder breakage and leaks can cause risk of personal injury

Shocks, e.g. caused by magnetic valves, should be avoided.

The measuring instruments must be used solely for the medium specified in the delivery note.

Media which differ from this may lead to impaired durability and therefore cause leakage

Using the manual

This manual contains information on the variable area flowmeters Q-Flow and V-100 and high-

precision control valves M-Flow.

Sections and paragraphs which only apply to a particular product group are marked as follows:

Variable area flowmeters Q-Flow

Variable area flowmeters V-100

High-precision control valves M-Flow

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

07

General information

Operating principle of the variable area flowmeter

The measuring instrument works according to the float measuring principle

The measuring unit consists of a tapered graduated precision glass measuring cylinder in which a

ball float can move freely up and down. The medium flows through the vertically-aligned measuring

cylinder from the bottom upwards.

The float positions itself so that the buoyancy force Aacting on it, the form resistance Wand its

weight Gare in balance::

G = A + W

The flow rate can be read as the height of the float on a scale on the tapered measuring cylinder.

The value is read off at the middle of the float (largest diameter).

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

08

Variable area flow meter type marking

The instrument type label is attached to the inside of the left side panel in the V-100 and on the

back of the mounting plate in the Q-Flow:

Example:

Key:

SN: Serial number –Position –number of instruments per position

BE: Customer order number

07/08: Date of manufacture, month/year

Type: Specification in accordance with type code (standard instruments only) 1

Medium, measuring range, measurement unit, pressure, temperature and additional information.

1Custom designed instruments are given a seven digit product code instead of a type code

(e.g. 137-1215).

High-precision control valve type marking

For the M-Flow the type label is attached to the valve cartridge housing.

An arrow on the body of the valve indicates the flow direction.

Example:

Key:

NS 2.5: Specification of valve size NS 1.0 to NS 6.5

L: Closing direction for valve (L = left / R = right)

V: Sealing material (V = FKM / E = EPDM / P = FFKM

Custom designed instruments can have additional details such as leakage rate.

SN: 483493-1-006 07/08

BE: 133526

Type: FLV-CSSA-SM

Air, 3.6-43 ln/min, 4 bar a, 20°C

mm-Scale

www.voegtlin.com - +41 61 756 63 00

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

09

Technical data

Technical data Q-Flow

Type

Q-Flow 55

Q-Flow 80

Q-Flow 140

Turndown ratio

10:1

10:1

10:1

Accuracy in % of full scale

± 5 %

± 4 %

± 2 %

Measuring tube length

55 mm

80 mm

140 mm

Scale length

40 mm

65 mm

120 mm

Float

spherical

spherical

spherical

Max. pressure

20 bar

20 bar

16 bar

Max. pressure drop

100°C

100°C

100°C

Materials Q-Flow

Component

Aluminium

Stainless steel

Top and base sections*

Anodized aluminum

Stainless steel 1.4305

Mounting plate

Anodized aluminum

Anodized aluminum

Measuring cylinder*

Borosilicate glass

Borosilicate glass

Connections*

Nickel-plated brass

Stainless steel 1.4305

Float*

SS 316 L / Glass / Ceramic

SS 316 L / Glass / Ceramic

Valve*

Nickel-plated brass

Stainless steel 1.4305

Seals*

FKM

FKM/EPDM

Front cover

Makrolon (Polycarbonate)

Makrolon (Polycarbonate)

Shock absorbing limit stop*

Stainless steel 1.4305 / PTFE

Stainless steel 1.4305 / PTFE

*Wetted parts

Setups Q-Flow

Standard (process connection on the back)

With valve Without valve

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

10

Technical data V-100

Type

V-100 55

V-100 80

V-100 140

Turndown ratio

10:1

10:1

10:1

Accuracy in % of full scale

± 5 %

± 4 %

± 2 %

Measuring tube length

55 mm

80 mm

140 mm

Scale length

40 mm

65 mm

120 mm

Float

spherical

spherical

spherical

Max. pressure

20 bar

20 bar

16 bar

Max. pressure drop

100°C

100°C

100°C

Materials V-100

Component

Aluminium

Stainless steel

Top and base sections*

Anodized aluminum

Stainless steel 1.4305

Mounting plate

Anodized aluminum

Anodized aluminum

Measuring cylinder*

Borosilicate glass

Borosilicate glass

Connections*

Nickel-plated brass

Stainless steel 1.4305

Float*

SS 316 L / Glass / Ceramic

SS 316 L / Glass / Ceramic

Valve*

Nickel-plated brass

Stainless steel 1.4305

Seals*

FKM

FKM/EPDM

Front cover

Makrolon (Polycarbonate)

Makrolon (Polycarbonate)

Shock absorbing limit stop*

Stainless steel 1.4305 / PTFE

Stainless steel 1.4305 / PTFE

*Wetted parts

Setups V-100 (position of the process connection)

Standard Setup L Setup R Setup A* Setup T* Setup O*

*A, T and O-Type in stainless steel only

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

11

Technical data M-Flow

Type

M-Flow 25

M-Flow 35

M-Flow V-Stack

Straight valve

Corner valve

Valve insert/cartridge

Gas distribution system

Ccw-closed

Valve turns

15

15

15

Valve size

NS 1.0 bis 3.0

NS 4 und 6.5

NS 4 und 6.5

Leak rate

<1x10-5 mbar l/s He

<1x10-5 mbar l/s He

<1x10-5 mbar l/s He

Max. pressure

20 bar

20 bar

20 bar

Min. temperature

-40°C

-40°C

-40°C

Max. temperature

150°C

150°C

150°C

Materials M-Flow

Component

Aluminium

Edelstahl

Valve*

Anodized aluminum

Stainless steel 1.4305

Valve insert/cartdrige *

Nickel-plated brass

Stainless steel 1.4305

Connections*

Nickel-plated brass

Stainless steel 1.4305

Seals*

FKM

FKM/EPDM/FFKM

* Wetted parts

Setups M-Flow

Straight valve Corner valve Distribution system V-Stack

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

12

M-Flow valve operation options

The following valve operation options are available (see also the type code of each instrument):

Standard-knob

Standard-knob with locking ring

Hex socket and locking nut (instead of standard-knob)

Digiturn with indication

(100 divisions, cw-closed valve only)

Digi-knob

(100 divisons, ccw-closed valve only)

basic valve right- or left-handed

thread made from brass or

stainless steel

stop ring 518-1552

manual knob

manual knob

headless screw M3x6 512-8204

headless screw M5x5

disc Ø10x6.4/0.5 518-1550

locking nut 518-1554

2 x headless screw M3x3 512-8201

2 x headless screw M3x4 512-8202

2 x headless screw M3x3 512-8201

2 x headless screw M4x10 512-8217

headless screw M3x6 512-8204

digiturn knob 633-1102

reducing bush 518-1575

collar ring 518-1563

cover ring 633-1104

stargrip to digiturn knob 633-1103

digivö knob 633-1101

digibase 518-1553

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

13

Measuring ranges variable area flowmeters

Measuring ranges direct reading scales ln/h (Air) and l/h (Water)

Medium

Air, ln/h

Water, l/h

Conditions

1.21 bara, 20°C

20°C

Type

Q-Flow 55

V-100 55

Q-Flow 80

V-100 80

Q-Flow 140

V-100 140

Q-Flow 55

V-100 55

Q-Flow 140

V-100 140

0.12-1.2

0.12-1.2

-

-

-

0.2-2

0.2-2

0.2-2

-

-

0.3-3

0.3-3

0.3-3

-

-

0.5-5

0.5-5

0.5-5

-

-

0.8-8

0.8-8

0.8-8

-

-

1.6-16

1.6-16

1.6-16

-

-

4-40

4-40

4-40

-

-

6-60

6-60

6-60

0.25-2.5

0.25-2.5

10-100

10-100

10-100

0.5-5

0.5-5

25-250

25-250

25-250

1.2-12

1.2-12

50-500

50-500

50-500

2.5-25

2.5-25

80-800

80-800

80-800

4-40

4-40

120-1200

120-1200

120-1200

6-60*

6-60

140-1400*

-

140-1400*

7-70*

7-70

-

-

200-2000*

-

-

*ranges available for V-100 instruments only

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

14

Measuring ranges direct reading scales mln/min and ln/min (Air)

Medium

Air, mln/min

Conditions

1.013 bara, 20°C

Type

Q-Flow 80 / V-100 80

Q-Flow 140 / V-100 140

10-120

10-100

20-240

40-220

60-640

50-540

Medium

Air, ln/min

Conditions

1.013 bara, 20°C

Type

Q-Flow 80 / V-100 80

Q-Flow 140 / V-100 140

0.1-1

0.1-1

0.3-2.2

0.2-2.2

0.5-5

0.5-6.0

0.2-10

1.5-10.5

2-20

2-26

4-32

6-51

Measuring ranges mm-scale Q-Flow

Medium

Air, ln/h

Water, l/h

Conditions

1.21 bara, 20°C

20°C

Measuring range

smallest

highest

smallest

highest

Q-Flow 80

0.04 –1.75

850 –3000

0.001 –0.03

0.8 –40

Q-Flow 140

0.15 –2.25

500 –5000

0.002 –0.03

12 –150

Measuring ranges mm-scale V-100

Medium

Air, ln/h

Water, l/h

Conditions

1.21 bara, 20°C

20°C

Measuring range

smallest

highest

smallest

highest

V-100 80

0.04 –1.75

100 –5000

0.0005 –0.015

10 –100

V-100 140

0.15 –2.25

500 –5000

0.001 –0.018

12 –150

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

15

CV-values high-precision control valves M-Flow

CV-values valves NS1.0 to NS6.5

CV-value 1 = 1 m3/h water at Δp of 1bar

0.0000001

0.000001

0.00001

0.0001

0.001

0.01

0.1

1

0 2 4 6 8 10 12 14 16

cv-values

spindle turns

NS-1.0

NS-1.5

NS-2.0

NS-2.5

NS-3.0

NS-4.0

NS-6.5

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

16

Installation and commissioning

General instructions

Measuring instrument design

In addition to the type code (see appendix) we require you to supply the following information for

optimal design of the instrument:

Medium

Maximum flow rate

For design without valve: Pressure in measuring cylinder

For design with valve: Pressure before and after the control valve

Temperature

When should the control valve be mounted at the outlet?

In vacuum processes the gas expands considerably. This leads to significant measurement

errors.

The control valve should therefore always be placed at the outlet for vacuum applications.

Liquids often contain gas bubbles. These settle on the float. This results in a higher flow rate

being displayed. By installing the control valve at the outlet the gas bubbles become smaller

and are better able to flow past the float.

In the case of fluctuating back pressure (e.g. when gassing a liquid container if the level varies

markedly).

In the case of pulsating media or smaller water hammer the valve at the outlet has a cushioning

effect.

When should the control valve be mounted at the inlet?

In the case of constant after-pressure

If the control valve also has to serve as a locking valve. (e.g. if a measuring cylinder has to be

exchanged when installed).

Direct reading scale or mm-scale?

The direct reading scale (also known as the product scale) is determined for only one operating

condition.

The mm-scale is not dependent on the medium, pressure and temperature. Different tables with

various operating conditions can be used. The actual measurement value is not visible directly on

the instrument but is read using a conversion table.

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

17

What is the purpose of standard liters and norm liters?

In contrast to liquids, gases can be compressed, so it is important to know the density of the gas

used. This in turn is dependent on pressure and temperature, i.e. if two quantities of gas are to be

compared with one another, then the current pressure in the pipe and the current temperature of

the medium must be known.

We supply general tables relating to norm liters 0°C 1013 mbar a

The two quantities are defined as follows:

Unit Pressure Temperature

Standard liter 1013.25 mbar a 20°Celsius

Norm liter 1013.25 mbar a 0° Celsius

The US standard liter corresponds to the German norm liter (0°C 1013.25 mbar a).

However, there are other reference temperatures. Gas suppliers use a reference temperature of 15

°C.

Conversion of standard liter (Stdl) into norm liter (ln) and vice versa:

Stdl = (ln/273.15)*293.15

ln = (Stdl/293.15)*273.15

Further information on this subject is given in the FAQs at www.voegtlin.com

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

18

Installation instructions

Before installing the measuring instrument, the pipe must be free of particles and moisture

The variable area flowmeter must be installed in a vertical position

The direction of flow is from the bottom upwards

The measuring instrument must be installed stress-free. Please use the mounting holes

provided for this purpose

The process connections must not be sealed with sealing tape or liquid sealer. Residues might

enter the instrument and lead to defects

(See also paragraph Recommended connections)

Before commissioning, make sure that the connections are sealed

Instructions for commissioning

The operating limits must not be exceeded

(See section Technical Information)

Connect the control valve to the flow meter or other control element

Open the media supply

Slowly open the control valve and set the required set value

(See also section Operating principle of the variable area flow meter)

Recommended connections

We recommend the following connections:

Pneumatic plug-in connection with O-ring or flat seal

Compression ring connection with O-ring or flat seal

Screw-in hose connection with O-ring or flat seal

Hose connectors with flat seal

Please note the available connection versions for our instruments and our range of accessories.

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

19

Panel mounting Q-Flow

For mounting, the panel opening must be prepared according to the diagram

Screw the two mounting brackets onto the instrument as shown

Screw the setscrew supplied into the connector and insert the instrument into the aperture from

the front

From the other side, hang the connectors in the openings of the mounting brackets

The instrument can be secured by careful tightening of the setscrews.

Panel aperture: Mounting-Kit:

Dimensions in mm

Type

D

Q-Flow 55

104.3

Q-Flow 80

129.3

Q-Flow 140

189.3

V-Flow Line

Manual

Version

Page

V-Flow Line

vflow_E4_7

© Vögtlin Instruments AG

20

Faceplate mounting V-100

For mounting, the faceplate must be prepared according to the diagram

The instrument is supplied with mounted plate and inserted into the aperture from the front.

Screw the plate to the control cabinet using suitable M3 screws

For retrofit installation, unscrew the glass front of the instrument and fit the plate in place of this

and install as described above

Panel aperture: Mounting-Kit:

Dimensions in mm:

Panel

Panel aperture

Type

A

B

C

D

E

S

T

U

V

W

V-100 55

133.5

123.5

19.5

33

20

121

1.5

123.5

32

20

V-100 80

178

168

30.5

33

23

146

13

168

32

23

V-100 140

262

252

45

33

23

206

27.5

252

32

23

This manual suits for next models

12

Table of contents

Other Vogtlin Measuring Instrument manuals

Vogtlin

Vogtlin Red-y compact 2 Series User manual

Vogtlin

Vogtlin red-y GCR User manual

Vogtlin

Vogtlin TEESING Q-Flow Series User manual

Vogtlin

Vogtlin SmartTrak 100 Series User manual

Vogtlin

Vogtlin red-y compact Series User manual

Vogtlin

Vogtlin Red-y compact 2 Series User manual

Vogtlin

Vogtlin Q-Flow User manual

Vogtlin

Vogtlin red-y industrial Series User manual

Vogtlin

Vogtlin red-y compact Series User manual