3

DTF 25 SH •Operating Manual Table Of Contents

12

Maintenance plan.............................................................................................................................................................. 12

Maintenance work............................................................................................................................................................. 13

13

13

14

15

Installation of the machine .............................................................................................................................................. 15

Mode of operation............................................................................................................................................................. 15

16

Housing assembly .............................................................................................................................................................17

Handle bar assembly .......................................................................................................................................................20

Wheel axle front complete ..............................................................................................................................................22

Wheel whip complete .......................................................................................................................................................22

Stearing gear complete....................................................................................................................................................23

..........................................................................................................................................................24

Vertical adjustement complete.......................................................................................................................................24

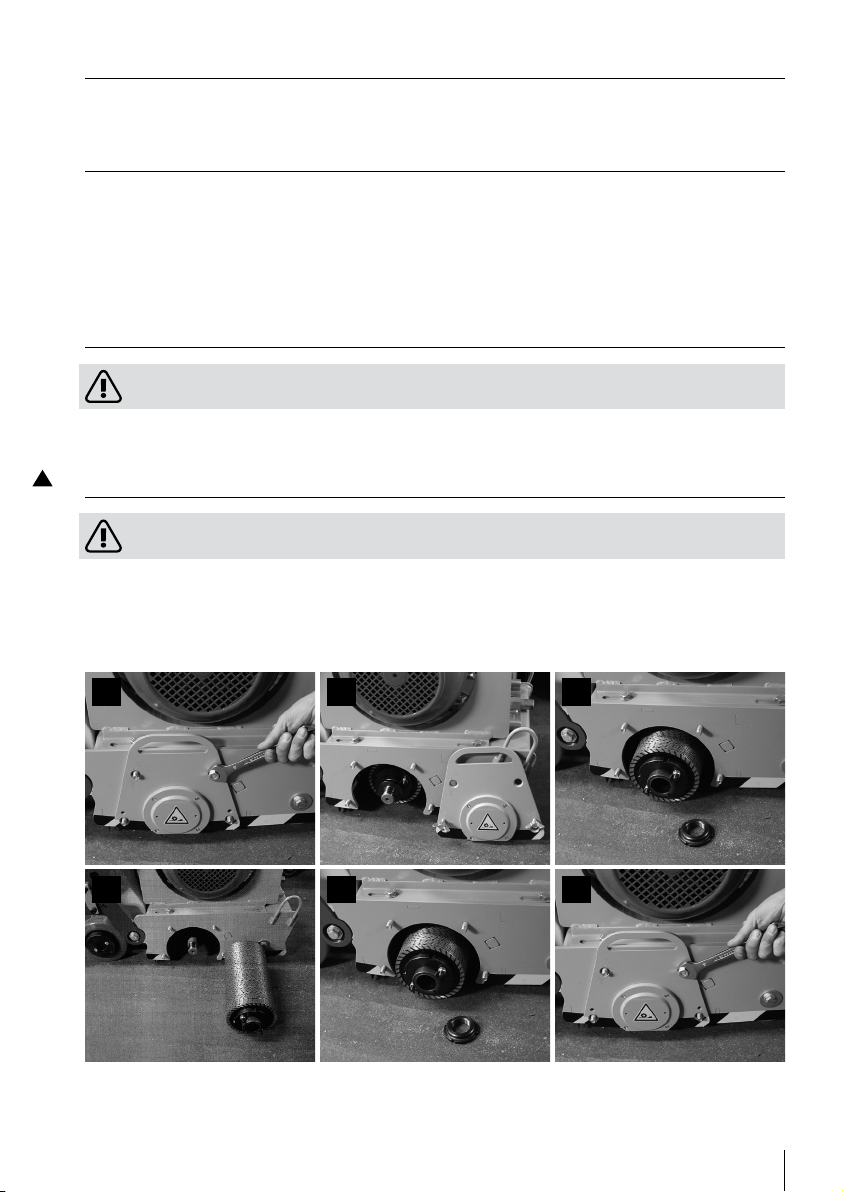

Motor assembled ..............................................................................................................................................................25

Belt guard complete .........................................................................................................................................................28

..............................................................................................................................................29

Spray tod complete...........................................................................................................................................................30

...............................................................................................................................................30

Spray tod complete........................................................................................................................................................... 31

...................................................................................................................................................... 31

Side attachment unit ........................................................................................................................................................32

...................................................................................................................................................32

Electrical switch set..........................................................................................................................................................33

Battery set..........................................................................................................................................................................33

Regulator assembled........................................................................................................................................................34

Electrical switch assembly ..............................................................................................................................................34

34

35

35

36

36

37

38

................................................................................................38