VRG Controls, LLC Page 6 of 8 09 JUL 2013

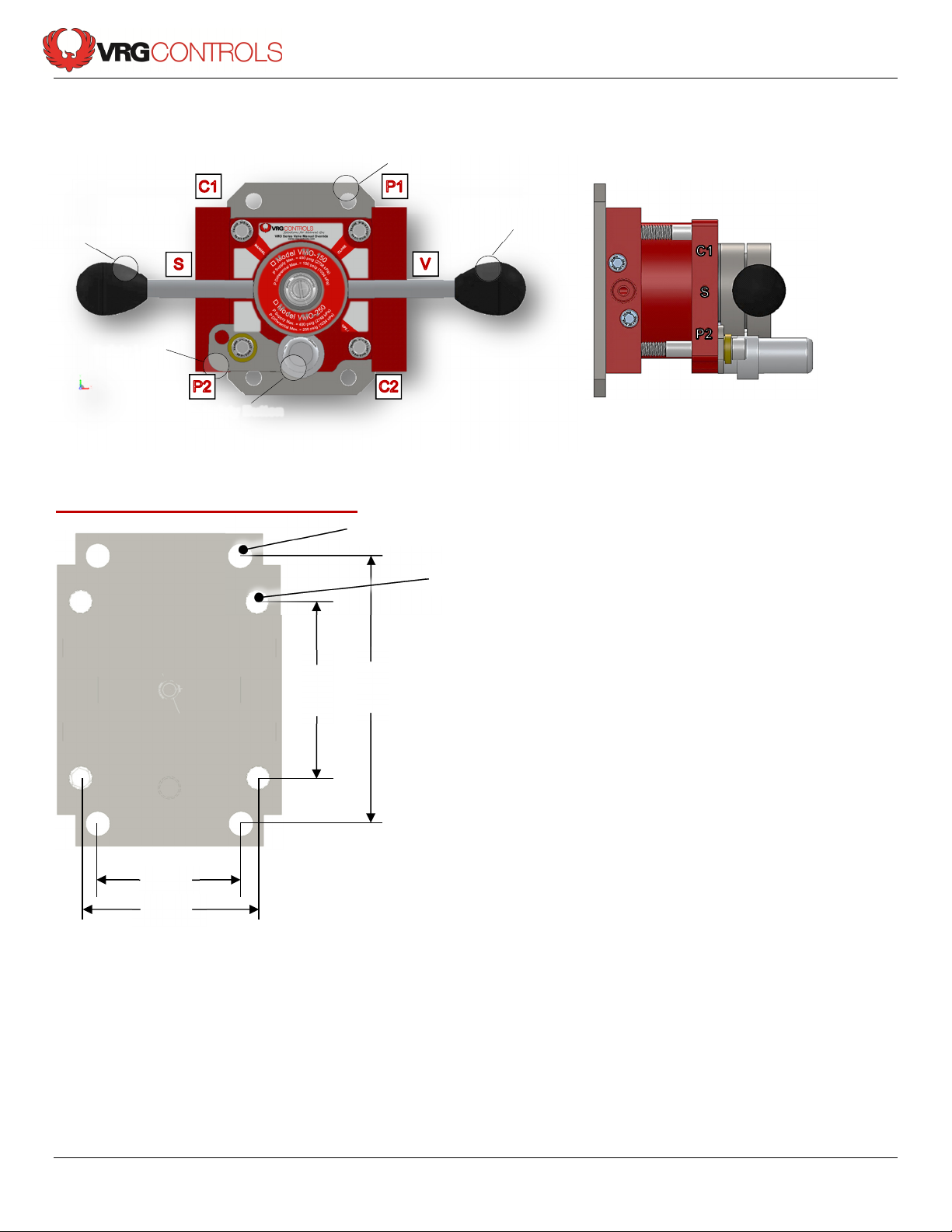

VPC Series Valve Pilot Controllers

VMO Operation Instructions

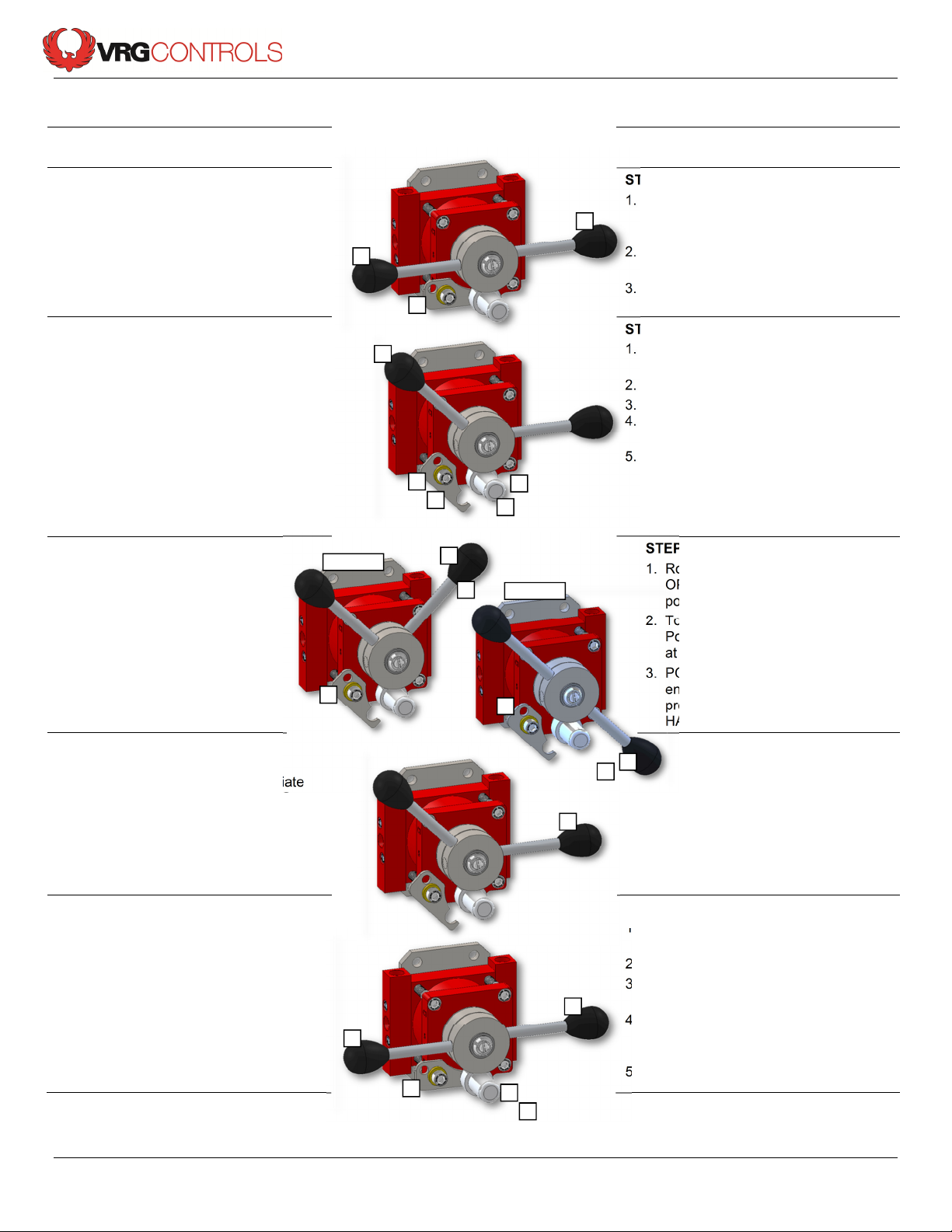

How to CLOSE Valve Using VMO Valve

Manual Override

How to OPEN Valve Using VMO Valve

Manual Override

STEP 1 – START AT AUTO MODE

1. Valve is in A TOMATIC MODE with

A TO/MAN AL HANDLE at A TO (A)

Position.

2. POSITION HANDLE is at NE TRAL (N)

Position.

3. SAFETY LOCK is engaged.

STEP 1 – START AT AUTO MODE

1. Valve is in A TOMATIC MODE with

A TO/MAN AL HANDLE at A TO (A)

Position.

2. POSITION HANDLE is at NE TRAL

(N) Position.

3. SAFETY LOCK is engaged.

STEP 2- ENGAGE MANUAL MODE

1. Remove padlock from SAFETY LOCK if

applicable.

2. Rotate SAFETY LOCK to disengage

3. Depress SAFETY B TTON

4. Rotate A TO/MAN AL HANDLE up to

MAN AL (M) Position.

5. Ensure that SAFETY B TTON releases

once A TO/MAN AL handle is at

MAN AL (M) mode to allow movement

of POSITIONING HANDLE.

STEP 2- ENGAGE MANUAL MODE

1. Remove padlock from SAFETY LOCK if

applicable.

2. Rotate SAFETY LOCK to disengage

3. Depress SAFETY B TTON

4. Rotate A TO/MAN AL HANDLE up to

MAN AL (M) Position.

5. Ensure that SAFETY B TTON releases

once A TO/MAN AL handle is at

MAN AL (M) mode to allow movement

of POSITIONING HANDLE.

STEP 3- MOVE TO CLOSE

1. Rotate POSITION HANDLE up to

CLOSE (C) position valve to

desired position.

2. To move valve to F LL CLOSED

Position, leave POSITION

HANDLE at CLOSE (C) position.

3. POSITION HANDLE LOCK may

be engaged for “lock out/tag out”

procedure. Optional POSITION

HANDLE LOCK not shown.

STEP 3- MOVE TO OPEN

1. Rotate POSITION HANDLE up to

OPEN (O) position valve to desired

position.

2. To move valve to F LL OPEN

Position, leave POSITION HANDLE

at OPEN (O) position.

3. POSITION HANDLE LOCK may be

engaged for “lock out/tag out”

procedure. Optional POSITION

HANDLE LOCK not shown.

STEP 4- STOP AT INTERMEDIATE

POSITION

1. Valve may be stopped in intermediate

position by returning POSITIONING

HANDLE to NE TRAL (N) position.

STEP 4- STOP AT

INTERMEDIATE POSITION

1. Valve may be stopped in

intermediate position by

returning POSITIONING

HANDLE to NE TRAL (N)

position.

STEP 5- RETURN TO AUTO MODE

1. Move POSITIONING HANDLE to

NE TRAL (N) Position

2. Depress SAFETY B TTON

3. Rotate A TO/MAN AL HANDLE to

A TO (A) Position.

4. Ensure that SAFETY B TTON releases

once A TO/MAN AL handle is at

A TO (A) mode

5. Engage SAFETY LOCK if applicable

STEP 5- RETURN TO AUTO MODE

1. Move POSITIONING HANDLE to

NE TRAL (N) Position

2. Depress SAFETY B TTON

3. Rotate A TO/MAN AL HANDLE to

A TO (A) Position.

4. Ensure that SAFETY B TTON releases

once A TO/MAN AL handle is at

A TO (A) mode

5. Engage SAFETY LOCK if applicable