Table of Contents

1Installation options ..............................................................................................................................................................................1

1.1 Electric heater in the non-insulated duct...................................................................................................................................1

1.2 Power slices in original AHU casing............................................................................................................................................1

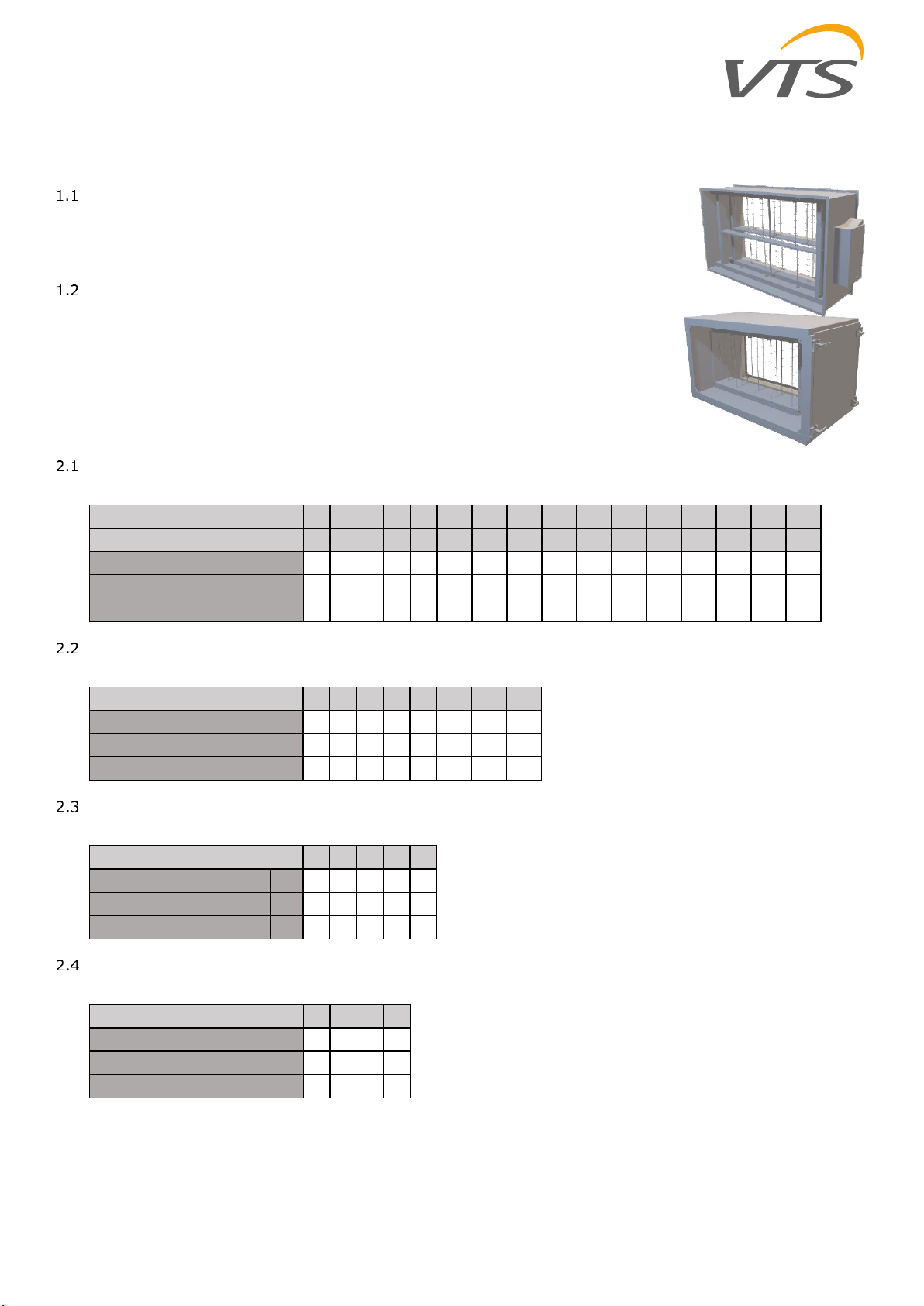

2Range of the application ......................................................................................................................................................................1

2.1 VVS Standard & AVS...................................................................................................................................................................1

2.2 VVSc compact floor mounted air handling unit .........................................................................................................................1

2.3 VVSs suspended compact air handling unit ...............................................................................................................................1

2.4 NVS ducted air handling unit......................................................................................................................................................1

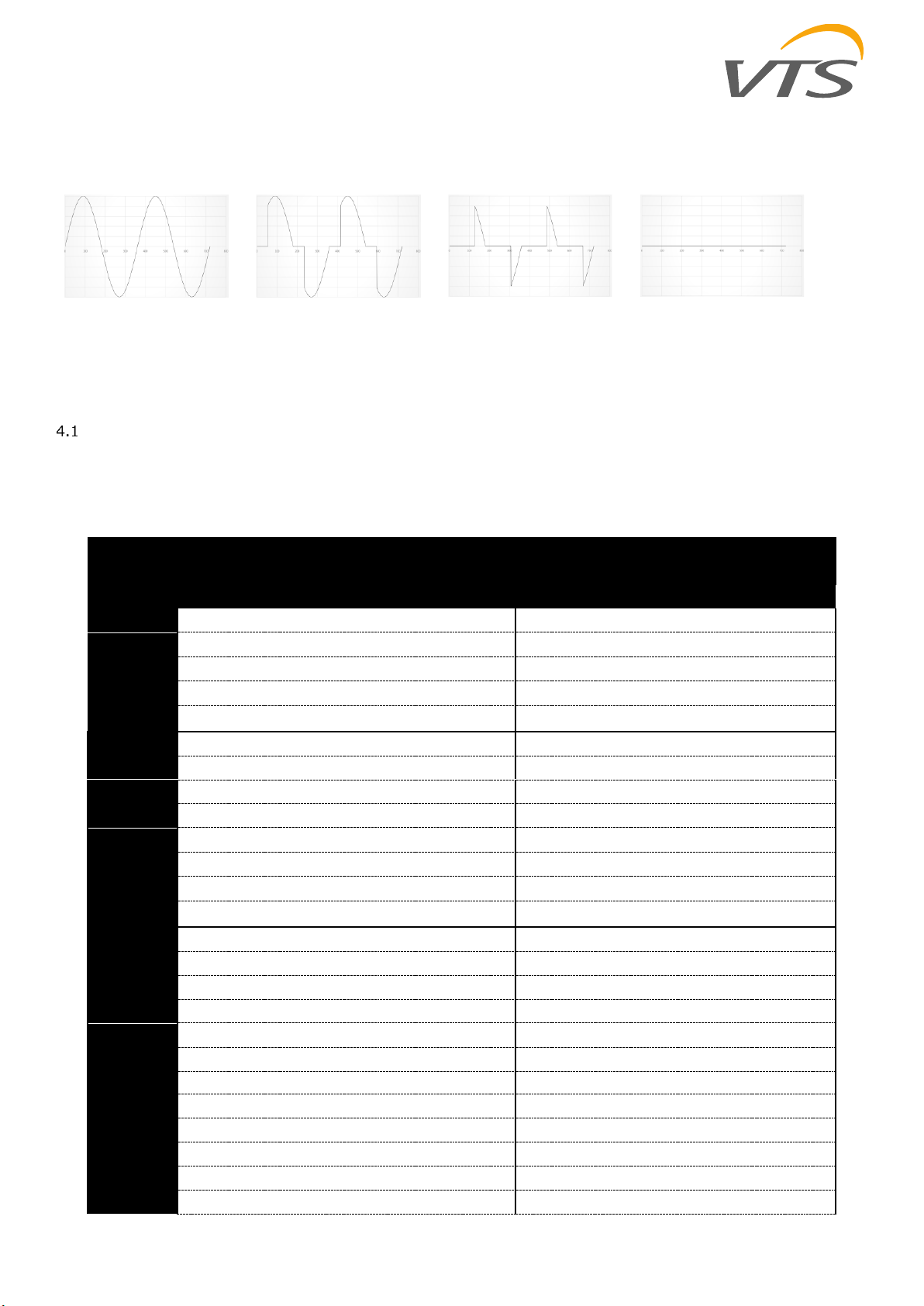

3SSR control...........................................................................................................................................................................................2

4Technical details...................................................................................................................................................................................2

4.1 Power and current details..........................................................................................................................................................2

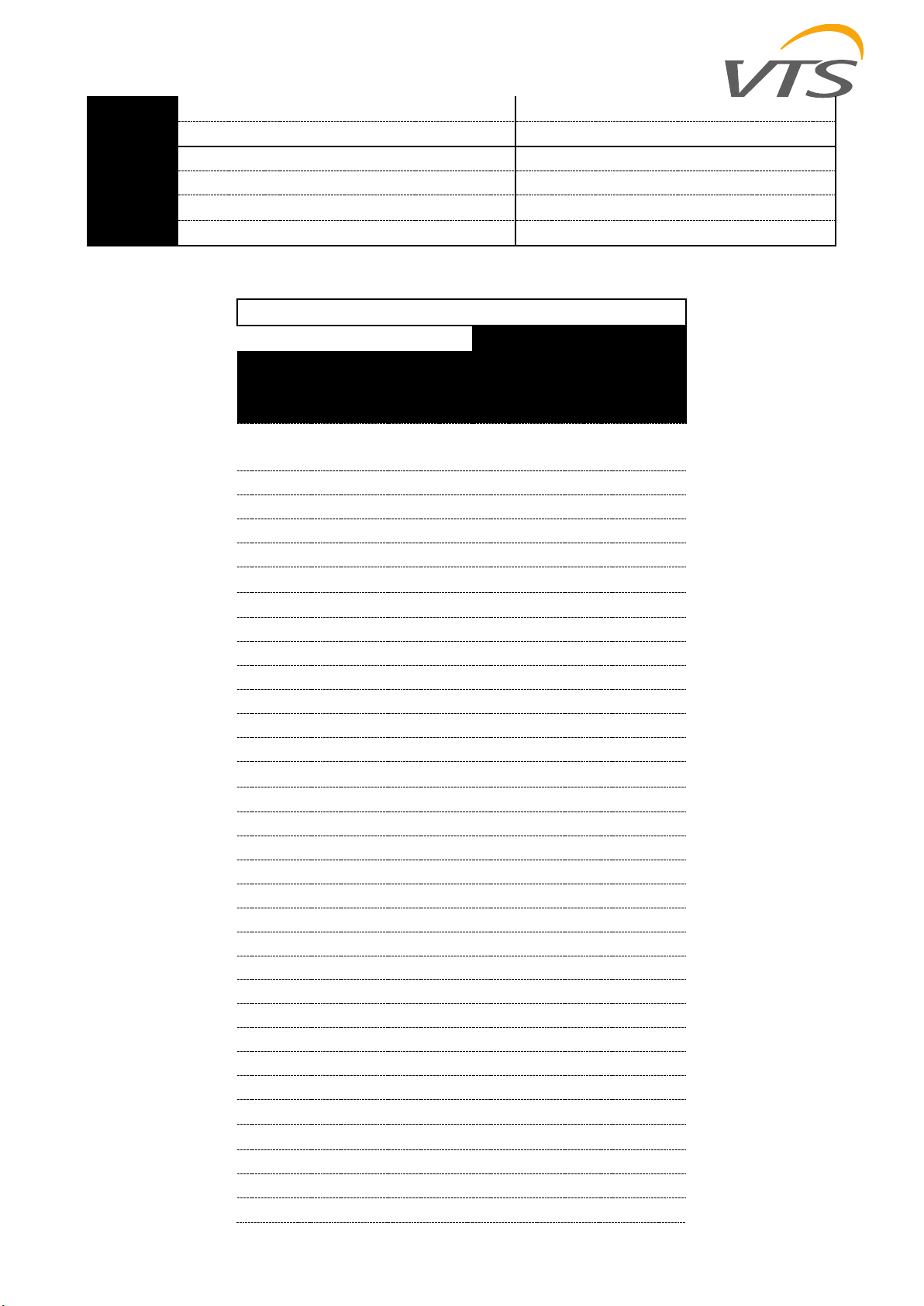

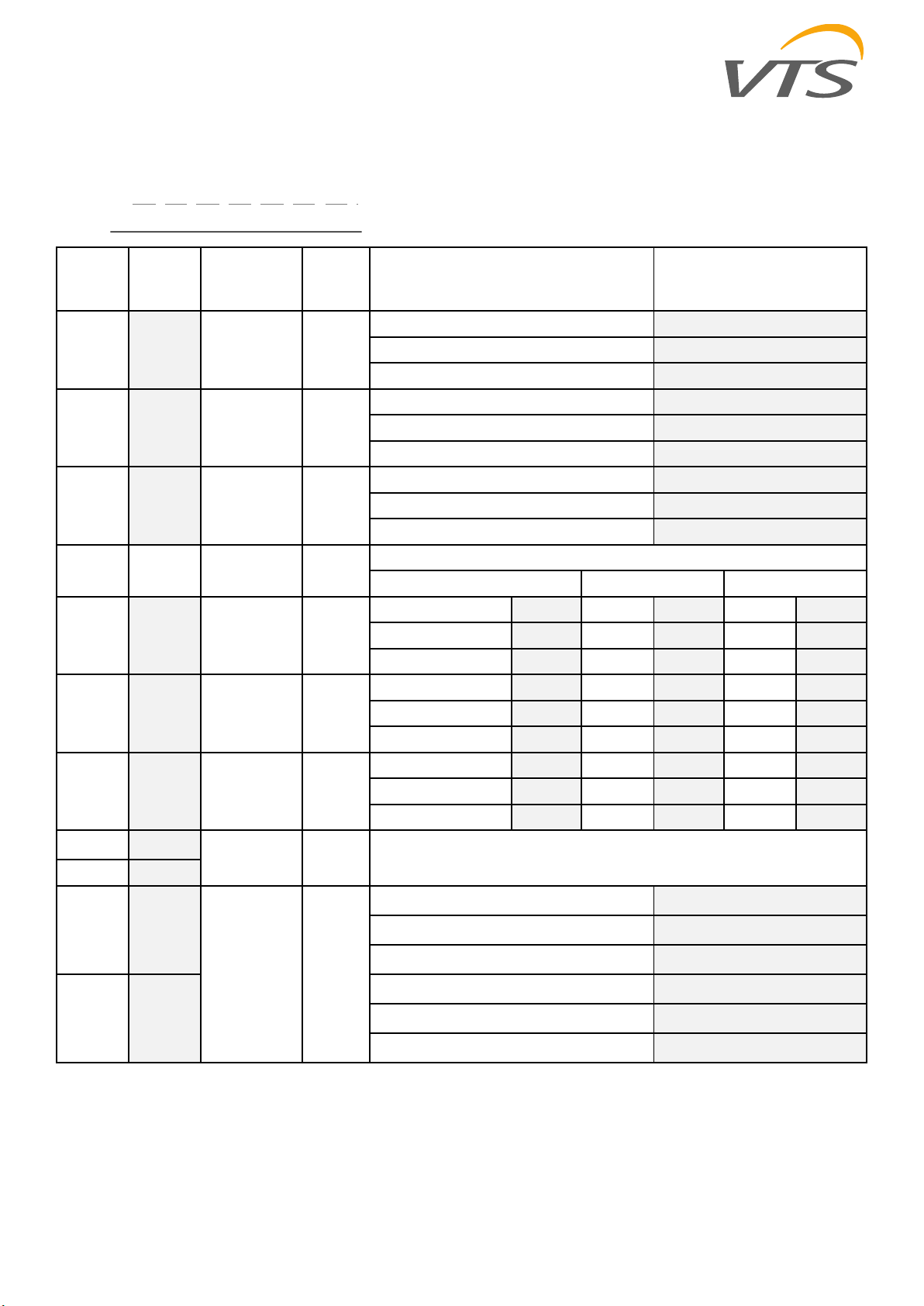

4.2 Electrical supply system details..................................................................................................................................................5

5Electrical connection............................................................................................................................................................................6

6Wiring cable types details....................................................................................................................................................................7

7Wiring schematics................................................................................................................................................................................8

7.1 1x18kW High power...................................................................................................................................................................9

7.2 1x18kW Low power..................................................................................................................................................................10

7.3 2x18kW High power.................................................................................................................................................................11

7.4 2x18kW low power ..................................................................................................................................................................12

7.5 4x18kW High power.................................................................................................................................................................13

7.6 4x18kW Low power..................................................................................................................................................................14

7.7 6x18kW High power.................................................................................................................................................................15

7.8 6x18kW Low power..................................................................................................................................................................17

8Maintenance Procedure ....................................................................................................................................................................19