C. Purge the Recoat Pump

After filling or removing the internal recoat bottle, the recoat pump must be purged of air in order to eliminate any

bubbles in the final recoat. Five (5) purge cycles are required to pump material completely through the pump and

remove any air. Each purge cycle will draw material from the bottom of the recoat bottle through the red fill tube and

inject the material back into the top of the recoat bottle through the green purge tube. To run the purge cycles:

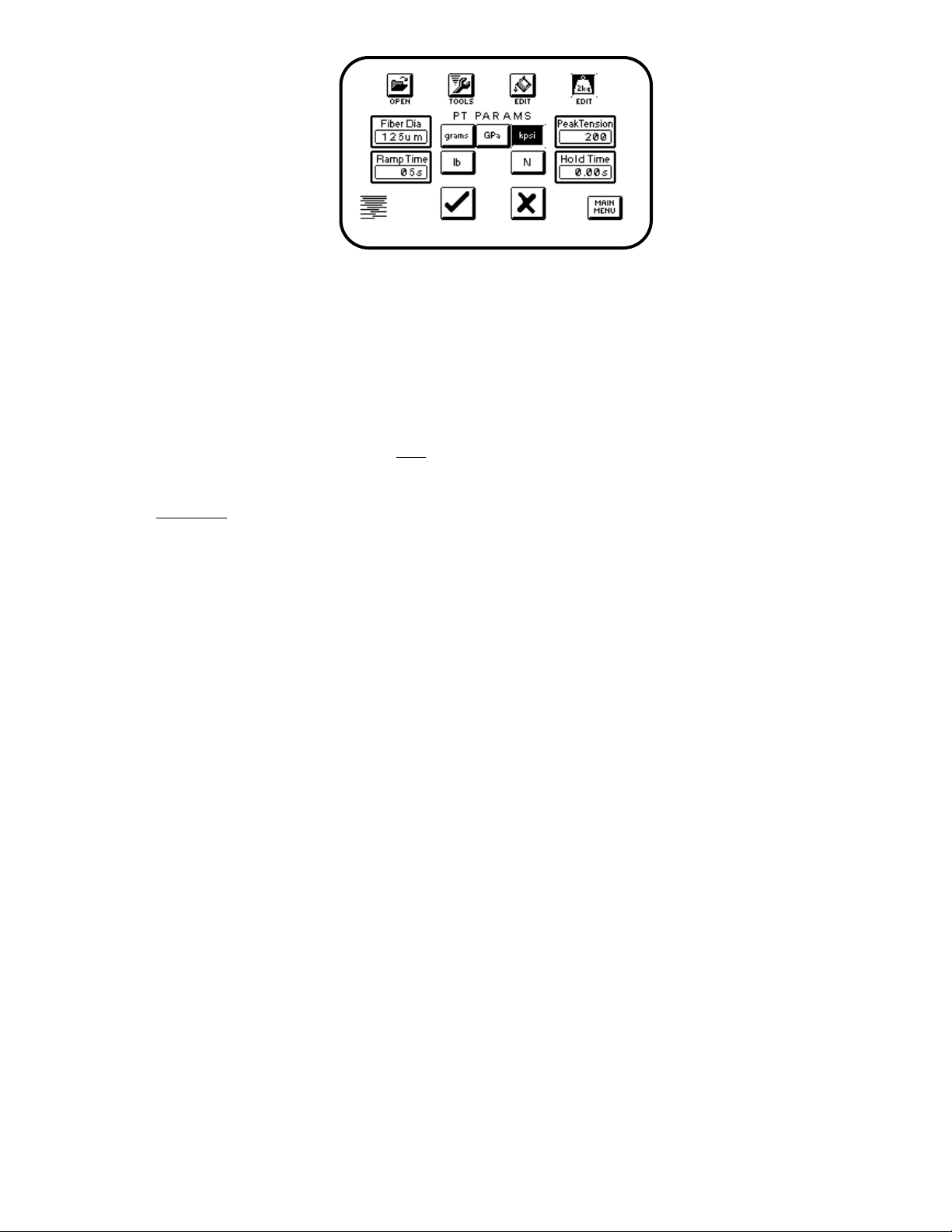

1. Select "TOOLS" from the Main Menu on the controller.

2. Highlight "PURGE" under the tools menu (see Fig. 3).

3. Type in "5" using the numeric keypad and touch the "" icon to proceed with the purge process. Note: If you

entered in an incorrect value, touch the "x" icon to cancel. Each purge cycle takes approximately 2-3 minutes.

The "" icon will remain highlighted until the process is completed.

D. Purge the Inject Tube

The recoat inject tube runs from the recoat pump to the recoat mold. Recoat material enters the mold at the center of

the back recoat mold plate. After purging the recoat pump, the inject tube must also be purged to remove trapped air.

Proceed as follows:

1. Make sure the recoat mold is opened. To open the mold, highlight "mold open" under the tools menu and select

the "" icon. Note: "Double click" the mold button to toggle between "mold open" and "mold close".

2. Make sure to have cotton swabs and cleaning solution (acetone or alcohol) available prior to proceeding. The

recoat material must be collected as it comes out of the mold injection port. Do not allow recoat material to run

down the face of the mold and under the mold plate.

3. From the "TOOLS" menu, select the "INJECT (µl)" icon, and, using the numeric keypad, enter in 50 for the

injection volume. You must inject 50µl three (3) times in order to purge air completely from the injection tube.

After keying in the inject value touch the "" icon to initiate the inject process. If an incorrect value was entered,

touch the "x" icon to cancel and re-enter the correct value. Make sure to collect the recoat material as it comes

out of the injection port. Note: The recoat injection pump can hold up to 100µl of recoat material. There will be

a delay of approximately one minute between the second and third injects while the pump refills with material.

4. After purging the inject tube, the recoat material should run freely from the mold without bubbles. If bubbles are

still present, run additional inject sequences.

5. Once purged, thoroughly clean both front and back mold plates with a cotton swab soaked in cleaning solution.

Note: Acetone is the preferred solution for cleaning the mold plates. Acetone cleans more thoroughly than

alcohol and will also soften and remove cured recoat material.

Figure 3 - Tools Menu.

PTR-200-ARL Quick Reference Guide Version 1.2 Page 4