Introduction

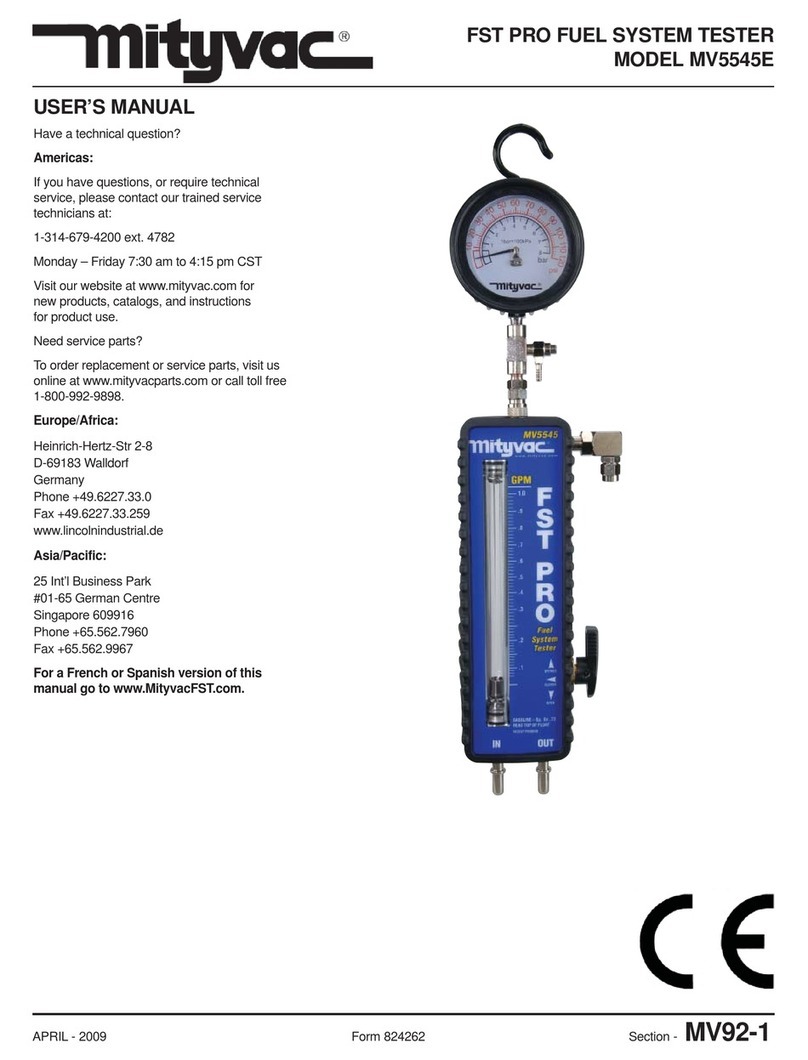

The Mityva FST Pro Fuel System Tester is an advan ed

diagnosti tool designed for troubleshooting and pinpointing

ommon automotive fuel delivery system malfun tions,

in luding:

• Failing fuel pump

• Faulty pressure regulator

• Blo ked inline filter

• Blo ked inlet strainer/so k

• Pin hed or rushed fuel line

• Fuel ontamination

• Fuel tank vortex

• Fuel system leaks

This manual fo uses on the appli ation of the FST to modern

ele troni fuel inje tion (EFI) systems. However, it is equally

apable of diagnosing earlier fuel inje tion systems su h as

throttle body inje tion (TBI), ontinuous inje tion (CIS) and even

pre-fuel inje tion arbureted systems. A separate low pressure

gauge is available from Mityva for systems that operate below

15 PSI (100 kPa).

Saf ty Pr cautions

The use of this servi e tool requires the exposure of highly

flammable gasoline. To prevent fires, explosions and/or severe

injury, always apply extra pre autions when diagnosing or

working on fuel systems.

The FST Pro is designed for servi ing a variety of vehi les in a

safe, onvenient manner. However, fuel delivery systems vary

widely between makes and models of vehi les, potentially

requiring additional steps or equipment to perform a proper

servi e job. The pro edures outlined in this manual are to serve

as guidelines for the use of this equipment. In addition to these

guidelines, always follow the manufa turer’s re ommended

pro edures when servi ing ea h unique vehi le. Use ommon

sense in the appli ation of this tester; and do not attempt to

for e a test on a fuel system for whi h this equipment is not

designed to perform.

This tester is designed for use on gasoline/petrol engines only.

It is safe for use with gasoline and most gasoline additives, but

is not ompatible with diesel fuel or alternative/flex fuels that

ontain ethanol.

• Always read arefully and understand instru tions prior to

using this equipment

• Wear safety glasses at all times

• Operate the vehi le only in a well ventilated area, and away

from potential sour es of flame or ignition.

• Prior to starting an engine, make sure all omponents of the

tester, body parts, and personal lothing are lear of rotating

engine omponents

• Avoid burns by remaining autious of engine parts that may

be ome hot when the engine is running

• Never leave a vehi le unattended while testing

• Che k and se ure all fuel system onne tions before

starting the vehi le or a tivating the fuel pump

• Wear gloves and prote tive lothing to avoid the onta t of

gasoline on skin. If onta t o urs, immediately wash the

area and perform ne essary first aid

• Always keep a fire extinguisher on hand when performing

fuel related diagnosti s. Make sure the extinguisher is rated

for fuel, ele tri al and hemi al fires

• Avoid spilling fuel on hot engine parts. Clean-up any fuel

spills immediately after they o ur.

Spec f cat ons

Maximum Flow Capa ity: 1.0 gallon/minute (3.8 liters/minute)

Maximum Rated Pressure: 200 PSI (1340 kPa) (13.8 bar)

Compon nts, S rvic Parts

and Acc ssori s

The Mityva FST Pro ombines the highest quality materials

and workmanship to reate a durable, finely tuned diagnosti

tool, whi h with proper are will provide years of valuable

servi e. All omponents are designed and quality ontrolled

in the U.S.

Following is a list of standard omponents, servi e parts and

a essories relating to model MV5545. Components and

a essories are available from your lo al Mityva distributor.

Servi e parts, warranty information and te hni al servi e

information are available at the onta t information shown on

the front of this user manual.

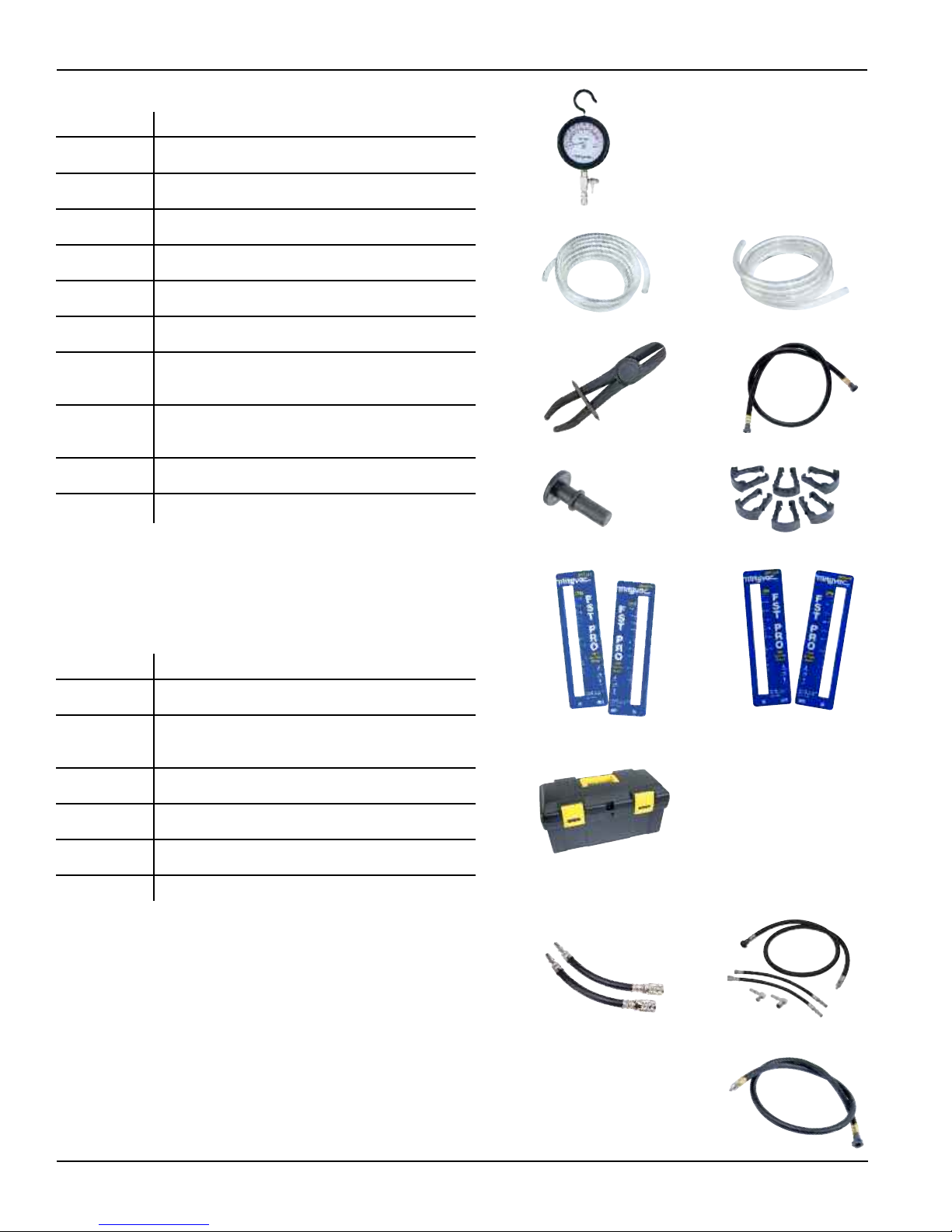

Standard K t Components

Model MV5545 in ludes the following high quality omponents:

• 3.5" (90 mm) diameter diaphragm style Pressure Gauge

- 0 to 120 PSI (0 to 8 bar) (0 to 800 kPa) s ale of measure

- Push-button pressure relief valve

- 360° swivel hook

- Prote tive rubber boot

• Flowmeter Assembly

- Borosili ate glass variable area flowtube with prote tive

shield and pre ision aluminum float

- 3-way Flow Control Valve

- Fuel bypass port

- Male push-to- onne t, qui k- hange oupler

w/ S hrader valve

- (2x) Male SAE J2044 qui k- onne ts

- Repla eable fa eplates with 0 to 1.0 gallon/minute

s ale of measurement

- Prote tive rubber boot

• (2x) Repla eable flowmeter fa eplates with 0 to 4 liters/

minute s ale of measurement

• 1/8" (3 mm) ID x 6' (1.8 m) long Pressure Relief Hose

• 1/4" (6.5 mm) ID x 6' (1.8 m) long Bypass Hose

• (2x) Flowmeter Conne tion Hose

• (2x) S issor Hose Clamp

• (2x) Hose Plug

• (6x) Qui k- onne t Repla ement Clip

• Custom Storage Case

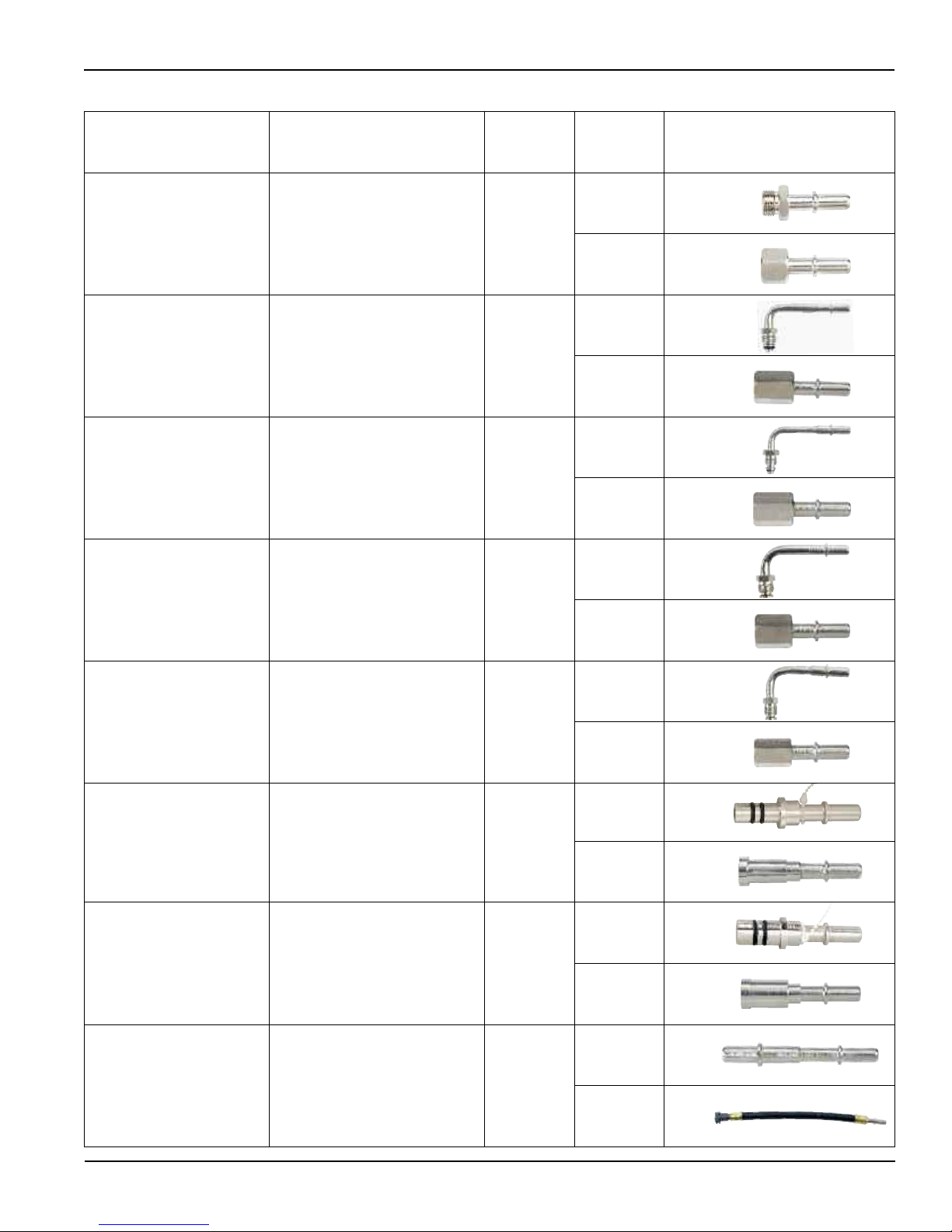

• Automotive Fuel System Test Adapters

(see Fuel System Test Adapters on page 6)

Page Numbe - 3