6

3.3. General safety instructions

Magnetic vibrators generate vibrations. The owner of vibration machines must

protect their employees against actual or possible risks to their health and safety

caused by the effect of vibrations.

Würges Vibrationstechnik GmbH refuses to accept the responsibility for any

damage to property or personal injuries if technical changes have been made to

the product or the instructions and regulations in this instruction manual have

not been noted and followed.

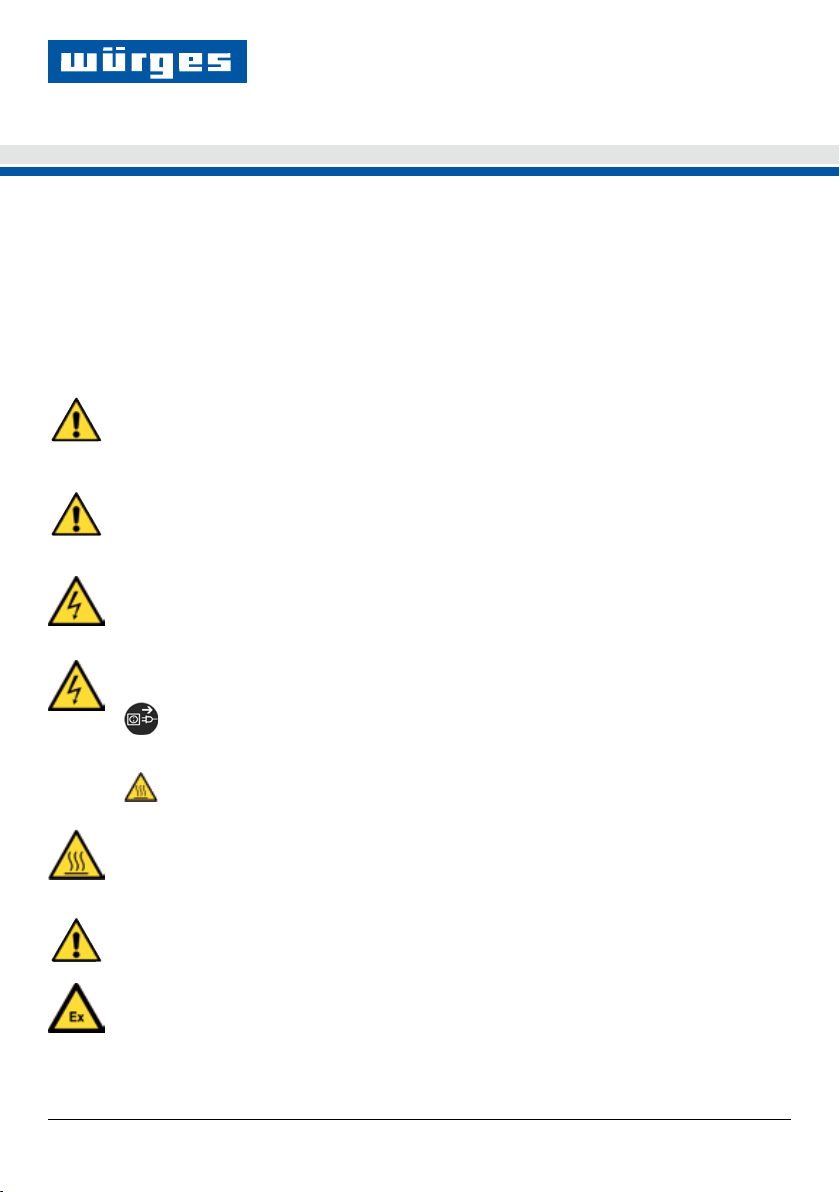

Live parts can cause severe or fatal injuries.

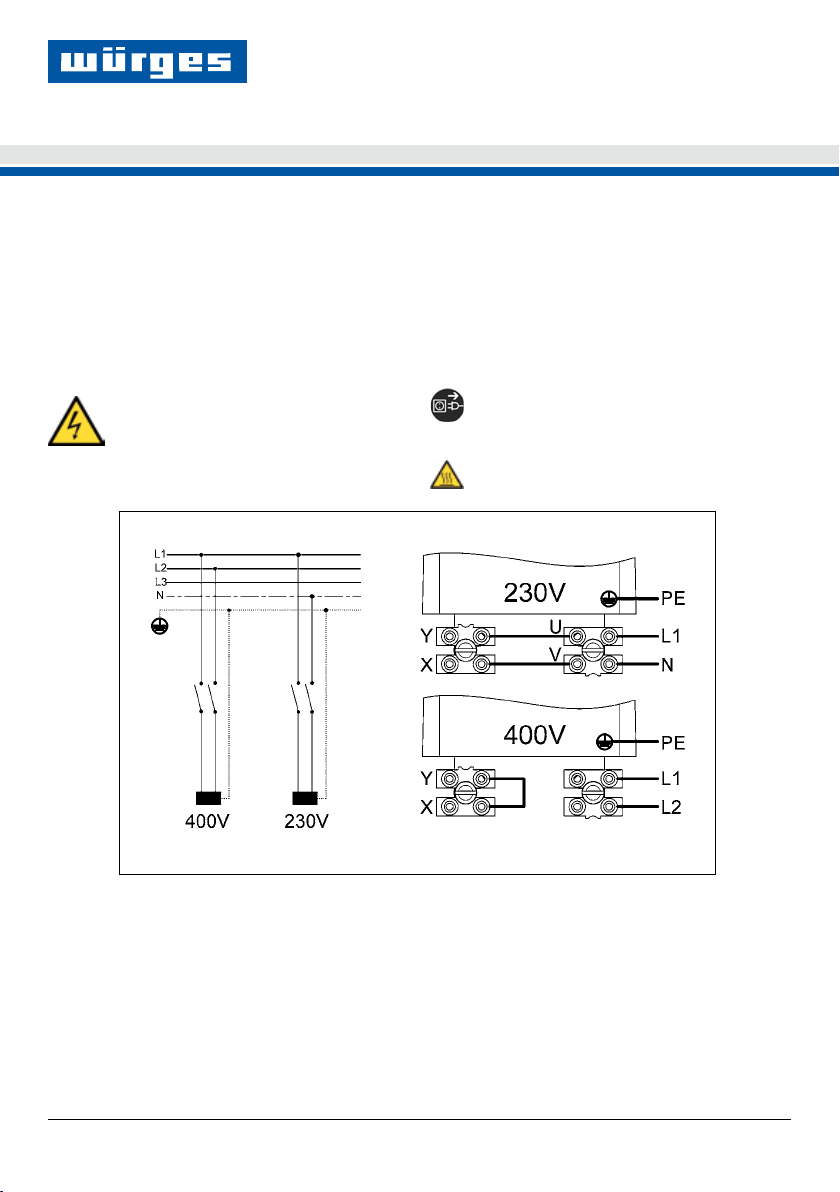

Electric vibrators must be safely disconnected from the electricity mains before

any work is carried out on them. The required procedure is as follows:

1. Switch off vibrator motor

2. Secure against being switched back on again

3. Test for safe disconnection from the power supply

4. Allow the vibrator motor to cool

Do not touch the vibrator motors while they are running or soon after switching

them off. The surface temperature of the vibrator motors can reach such high

values during operation that there is a risk of burns.

Always use a torque wrench when Tightening screws or bolts! Tightening

torques see page 9.

MR 1 series magnetic vibrator motors may not be used in hazardous areas (po-

tentially explosive atmospheres).