INTRODUCTION ...................................... 1

Message to the Owner and Operator ..... 1

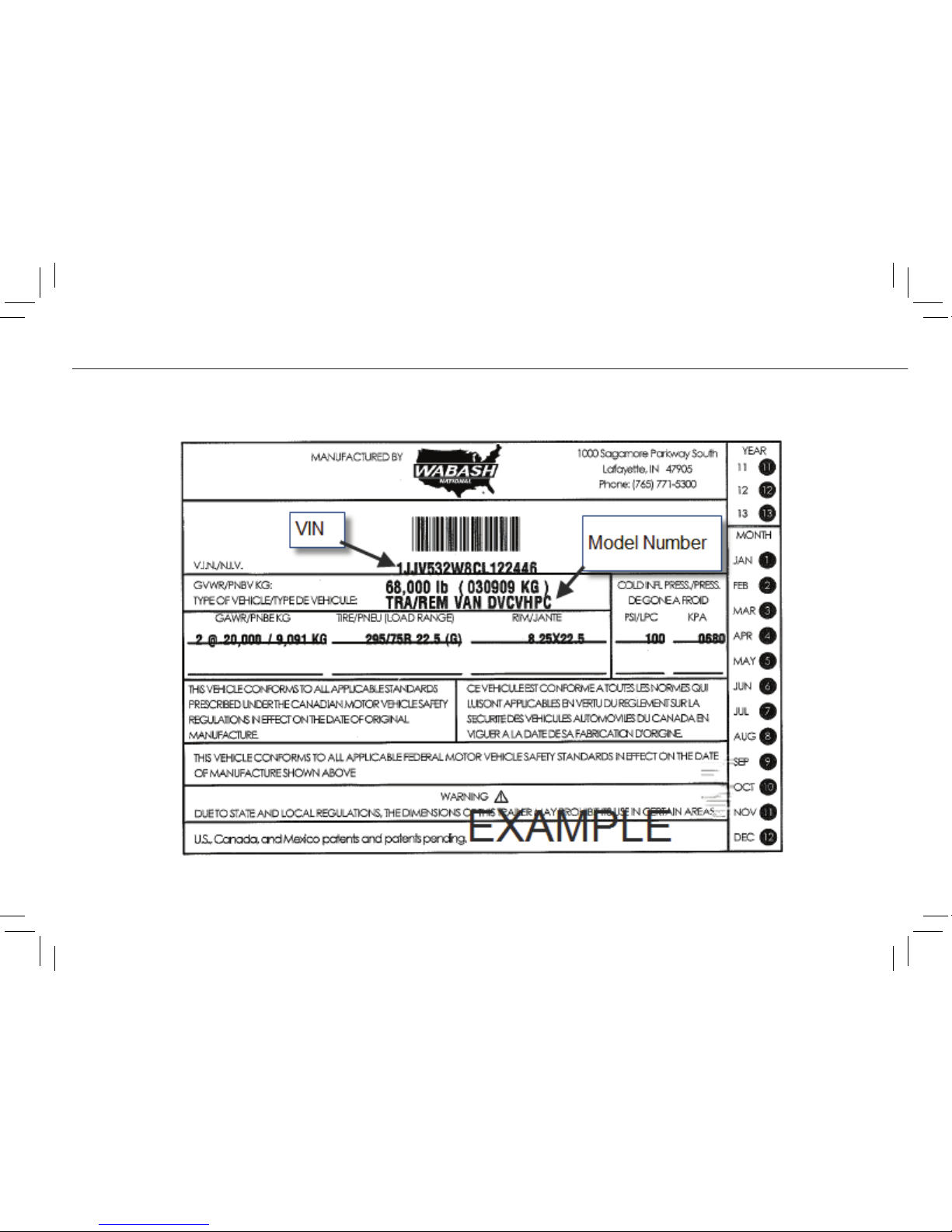

Identication ........................................... 1

How to Use This Operator’s Manual ...... 3

Trailer Accessories ................................. 3

SAFETY ................................................... 4

Safety Instructions ................................. 4

Notice ..................................................... 5

Safety Advisory Labels ........................... 5

SYSTEMS AND FEATURES .................... 6

Kingpin and Upper Coupler .................... 6

Floor System .......................................... 6

Roof System .......................................... 9

Doors .................................................... 10

Swing Doors ......................................... 10

Overhead Doors ................................... 11

Before Operating .................................. 12

During Operation .................................. 12

Rear-Impact Guard ...............................13

Landing Gear ........................................ 14

Operating Instructions .......................... 15

Electrical System .................................. 17

Air Systems .......................................... 18

Brake System ....................................... 19

Brake Air System .................................. 19

Anti-Lock Brake System ....................... 21

Foundation Brake System .................... 23

Air-Ride Suspension .............................26

Leaf Spring Suspension ....................... 27

Hubs ..................................................... 28

MAINTENANCE AND LUBRICATION .... 29

Lubrication ........................................... 29

Wheel Ends ......................................... 29

Doors ................................................... 29

Tire Care .............................................. 30

Limiting Factors and Load Limits ......... 30

OPERATION .......................................... 31

Hookup/Coupling and Uncoupling ...... 31

Sliding the Tandem ............................... 32

Refrigerated-Trailer Cooling Unit .......... 33

Safety Appliances ................................. 33

INSPECTION ......................................... 35

Operator’s Pre-Trip Inspection ............. 35

CONCLUSION ....................................... 37

For More Information ........................... 37

©2011 Wabash National, L.P. All rights reserved Wabash

®

, Wabash

National

®

, and DuraPlate

®

are marks owned by Wabash National, L.P.