2 UR3274U - User manual

Summary

1 Safety instructions........................................................................... 5

1.1 General instructions .............................................................. 5

1.2 Intended Usage ...................................................................... 6

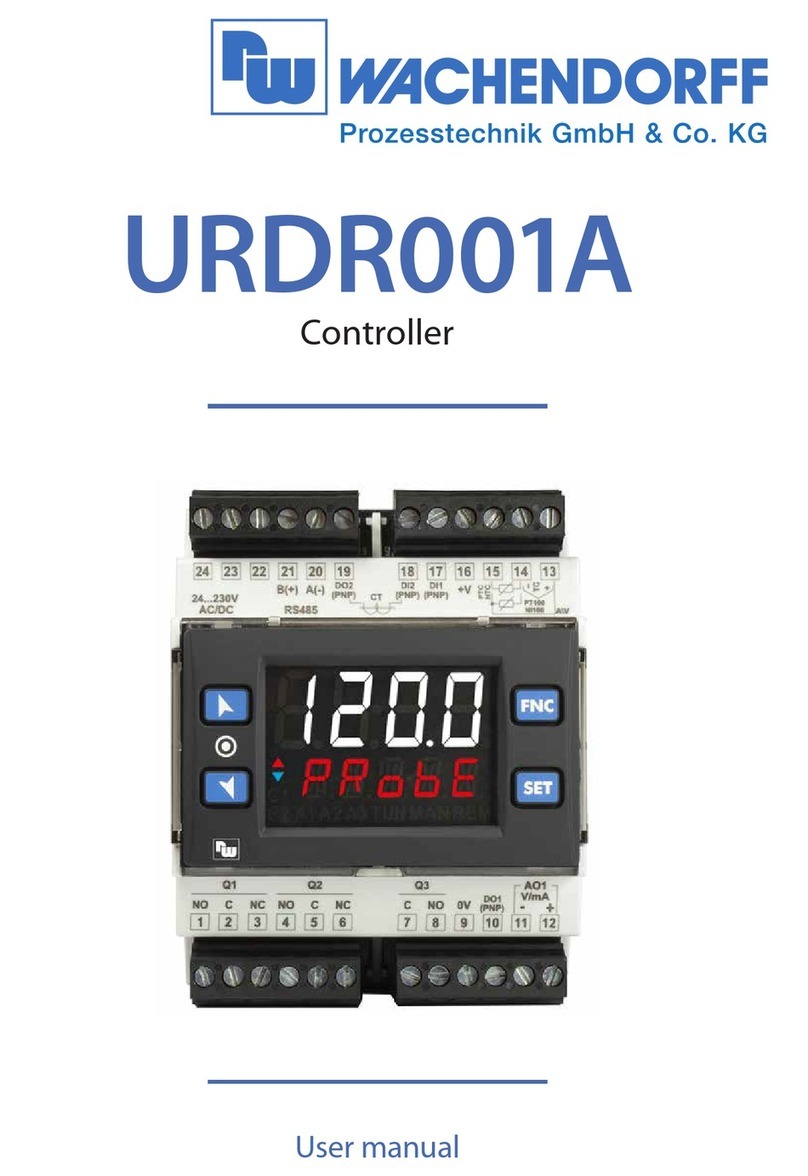

1.3 Qualied personnel ............................................................... 6

1.4 Remaining hazards ............................................................... 6

1.5 CE Conformity ......................................................................... 7

2 Model Identication........................................................................ 7

3 Technical Data.................................................................................. 7

3.1 General Features..................................................................... 7

3.2 Hardware Features................................................................. 8

3.3 Software Features .................................................................. 9

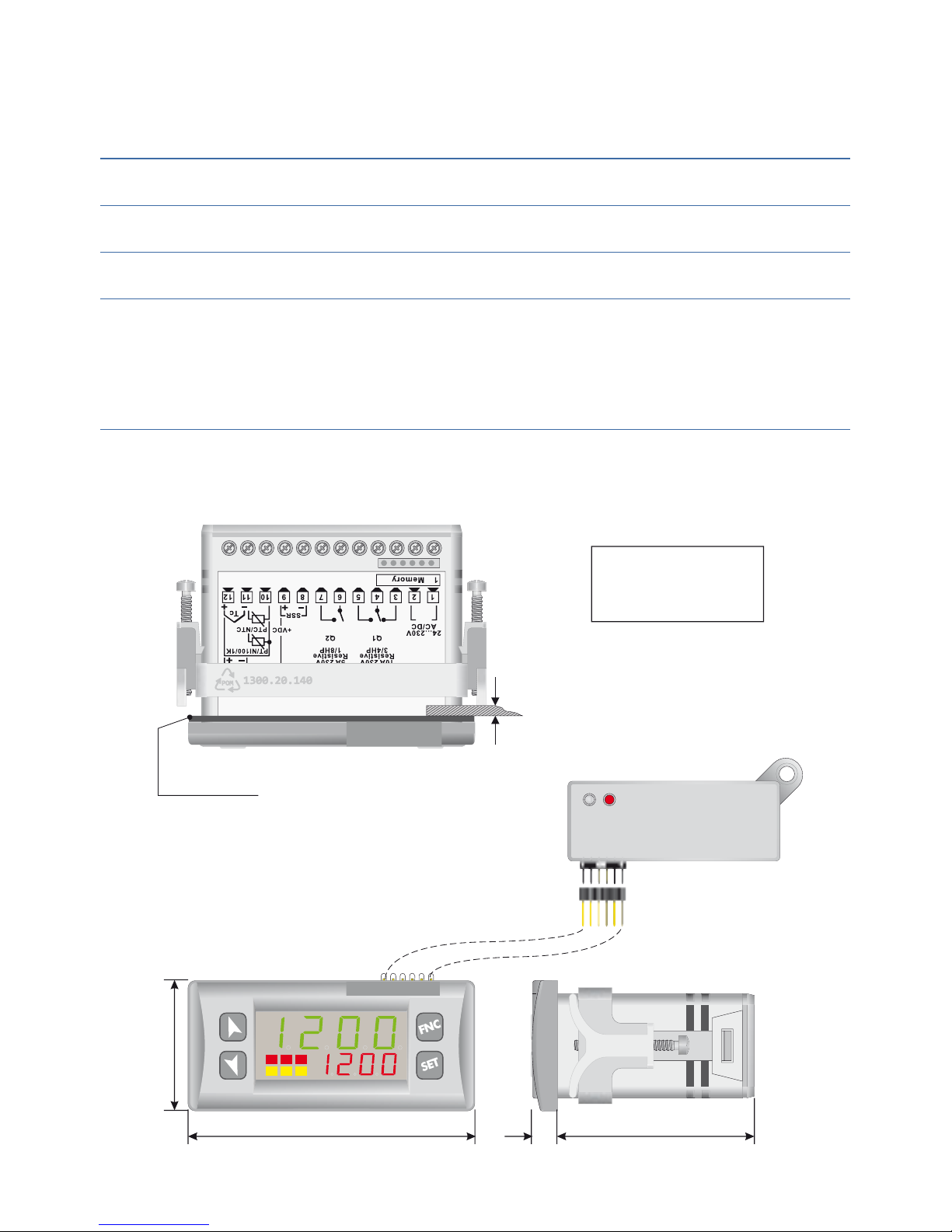

4 Dimensions and Installation......................................................... 9

5 Electrical wirings ..........................................................................10

5.1 Wiring diagram.....................................................................10

6 Display and Keys Functions.........................................................14

6.1 Numeric Indicators (Display).............................................14

6.2 Meaning of Status Lights (Led) .........................................14

6.3 Keys .......................................................................................15

7 Controller Functions......................................................................15

7.1 Modifying Main Setpoint and Alarm Setpoint Values.15

7.2 Auto-Tune...............................................................................16

7.3 Manual Tuning......................................................................16

7.4 Automatic Tuning ...............................................................16

7.5 Soft Start.................................................................................17

7.6 Automatic/Manual Regulation for % Output Control 17

7.7 Pre-Programmed Cycle.......................................................18

7.8 Programming module ........................................................18

7.9 Loading default values........................................................19