241.805.012 5 Date: 2017-10-24

Index

SAFETY INFORMATION 2

INDEX 4

TECHNICAL SPECIFICATIONS 6

DRAWING 7

INTRODUCTION 8

PACKAGE CONTENT .........................................................................................8

DESCRIPTION................................................................................................8

SAFETY FUNCTIONS .........................................................................................8

AREA OF USE................................................................................................9

USING FOR THE FIRST TIME..................................................................................9

TRANSPORT................................................................................................10

PHYSICAL INSTALLATION 11

FASTENING THE WINCH TO A FLAT SURFACE ................................................................11

MOUNTING THE WINCH ON A TRUSS ........................................................................11

MOUNTING THE LOAD ......................................................................................12

AC POWER 13

POWER CABLES AND POWER PLUG ..........................................................................13

INSTALLING A POWER INPUT CONNECTOR ON A POWER CABLE...............................................13

DATA LINK 14

TIPS FOR RELIABLE DATA TRANSMISSION ....................................................................14

CONNECTING THE DMX ....................................................................................14

SET UP 15

BLOCK DIAGRAM ...........................................................................................15

COUNTERBALANCE -SLACK WIRE ..........................................................................15

CONNECTIONS .............................................................................................15

EMERGENCY STOP..........................................................................................16

MODE SETTING............................................................................................16

DMX ADDRESS SETTING ..................................................................................18

MANUAL RESET.............................................................................................20

POSITIONING...............................................................................................20

RE-CALIBRATING OVERLOAD................................................................................21

SYNCHRONIZED MOVEMENTS OF MULTIPLE WINCHES.........................................................21

CONTROLLING THE SOFT TOP AND BOTTOM LIMITS .......................................................22

SERVICE AND MAINTENANCE 23

PARTS .....................................................................................................23

MAINTENANCE PLAN........................................................................................24

CHECKLIST.................................................................................................24

ON-SITE SERVICE...........................................................................................25

LIFE OF THE WIRE..........................................................................................25

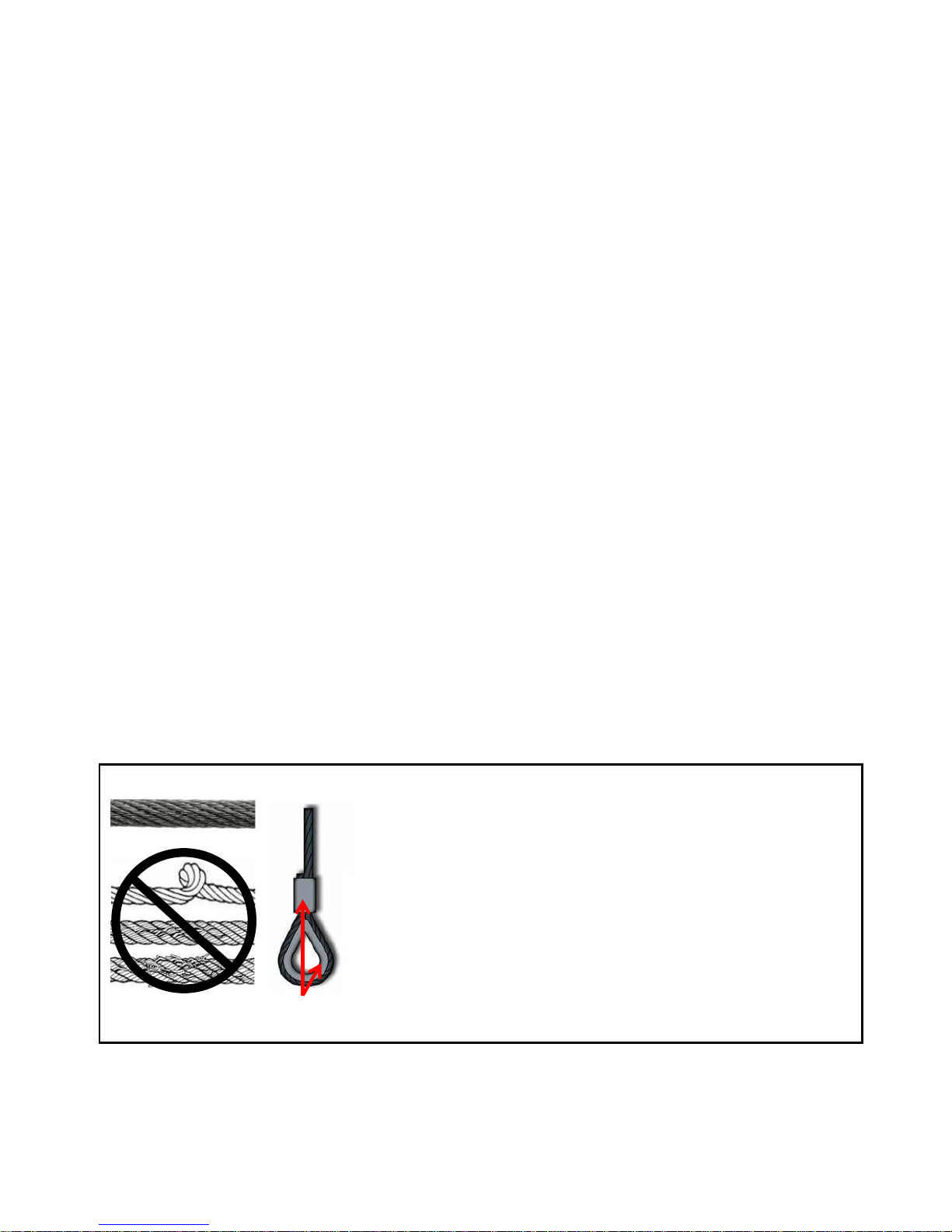

WIRE DEFECT ..............................................................................................26

WIRE DISCARD CRITERIA....................................................................................27

CHANGING WIRE ...........................................................................................28

APPLYING WIRE ............................................................................................33

POWER DEFECT ............................................................................................33

APPENDIX 1 34

APPENDIX 2 35

APPENDIX 3 37

WINCH 10 - CHEAT SHEET 38