5

805.281.001 Date: March 22rd, 2017

Index

SAFETY INFORMATION 2

INDEX 3

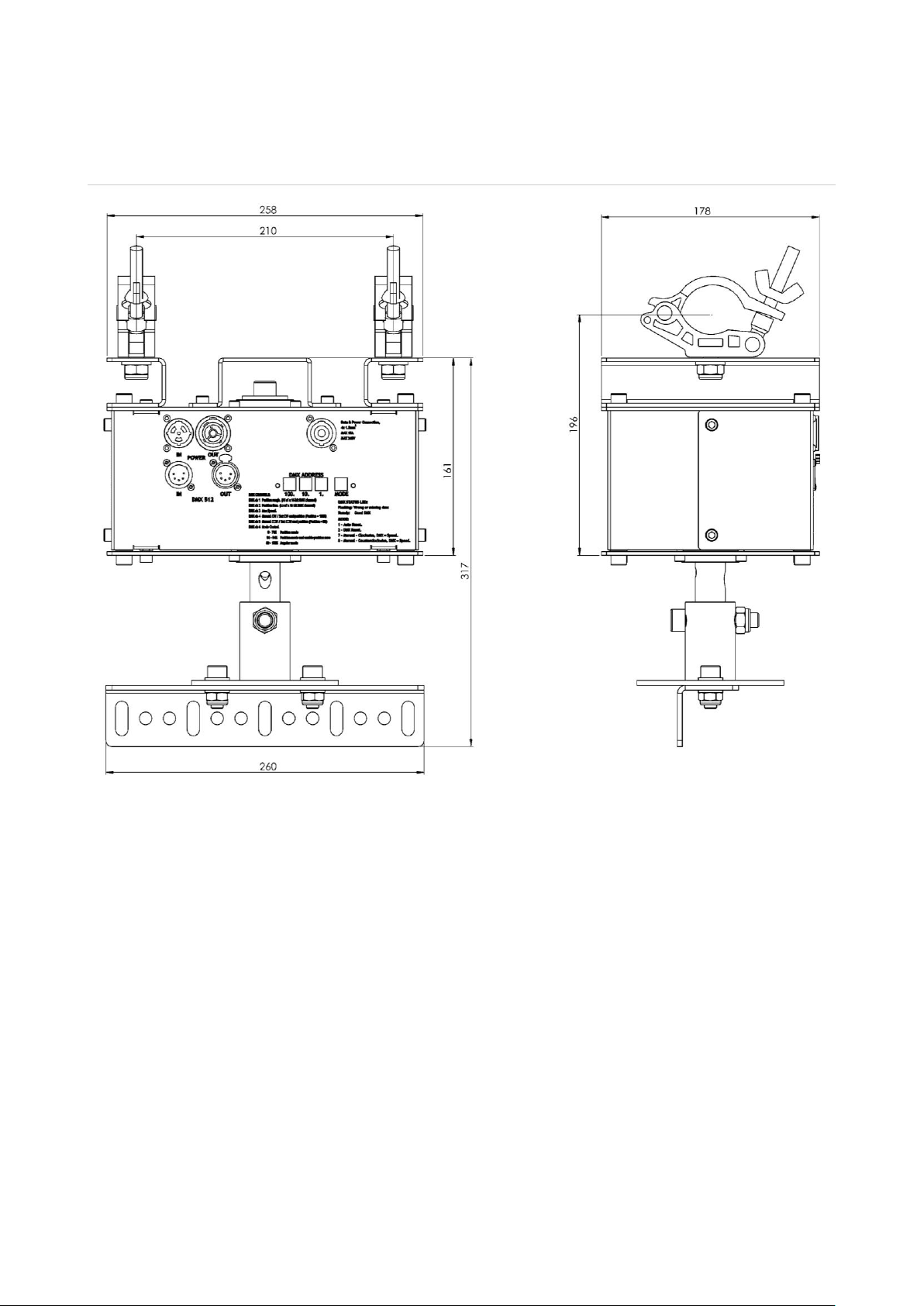

TECHNICAL SPECIFICATIONS 6

INTRODUCTION 8

PACKAGE CONTENT ...................................................................................................................................... 8

DESCRIPTION............................................................................................................................................... 8

AREA OF USE............................................................................................................................................... 9

USING FOR THE FIRST TIME ............................................................................................................................ 9

PHYSICAL INSTALLATION 10

FASTENING THE ROTATOR TO A FLAT SURFACE................................................................................................. 10

MOUNTING THE ROTATOR ON A TRUSS .......................................................................................................... 10

MOUNTING THE ROTATOR IN AN ANGLE......................................................................................................... 10

AC POWER 11

POWER CABLES AND POWER PLUG ................................................................................................................ 11

INSTALLING A POWER INPUT CONNECTOR ON A POWER CABLE ........................................................................... 12

DATA LINK 14

TIPS FOR RELIABLE DATA TRANSMISSION ........................................................................................................ 14

CONNECTING THE DATA LINK........................................................................................................................ 14

ATTACHMENT POWER AND DATA LINK 14

POWER VOLTAGE ....................................................................................................................................... 15

ATTACHMENT CONNECTION PLUG................................................................................................................. 15

CONNECTING THE POWER CABLE .................................................................................................................. 15

CONNECTING THE DATA LINK........................................................................................................................ 15

SETUP 16

MODE SETTING ........................................................................................................................................ 17

DMX ADDRESS SETTING ........................................................................................................................... 19

MANUAL RESET ......................................................................................................................................... 20

POSITIONING............................................................................................................................................. 21

SYNCHRONIZED MOVEMENTS OF MULTIPLE ROTATORS ..................................................................................... 22

SERVICE AND MAINTENANCE 23

MAINTENANCE PLAN .................................................................................................................................. 23

ON-SITE SERVICE........................................................................................................................................ 24

LIFE TIME OF THE ROTATOR.......................................................................................................................... 24

SPARE PARTS............................................................................................................................................. 24

POWER DEFECT.......................................................................................................................................... 24

ROTATOR 281 - CHEAT SHEET 25