WS100/12 Product Manual

Regulator Operation

Page 9

USING THE WAKESPEED WS100 REGULATOR

Once the WS100 regulator is properly wired to the alternator and

congured for your battery type, the regulator is ready to begin charging

your batteries. Following a short delay, the regulator will begin to ramp

up charging voltage to a bulk target voltage that’s determined by your

charging prole selection.

Once the regulator reaches bulk target voltage, the regulator will continue

to hold at target until the eld pulse width falls below its target level, and

the regulator will advance to the acceptance target voltage (typically two-

tenths of a volt below bulk target voltage). The regulator will continue

to charge at acceptance target voltage until the eld pulse width drops

below minimum target, at which point, the regulator will advance to oat

voltage.

While at target voltage for oat, the regulator will monitor the eld pulse

width. If the maximum oat pulse width cannot maintain the target voltage

for oat charging, the regulator will return to acceptance charging voltage.

During extended engine operation and under varying battery loads, the

voltage may cycle between charge modes multiple times.

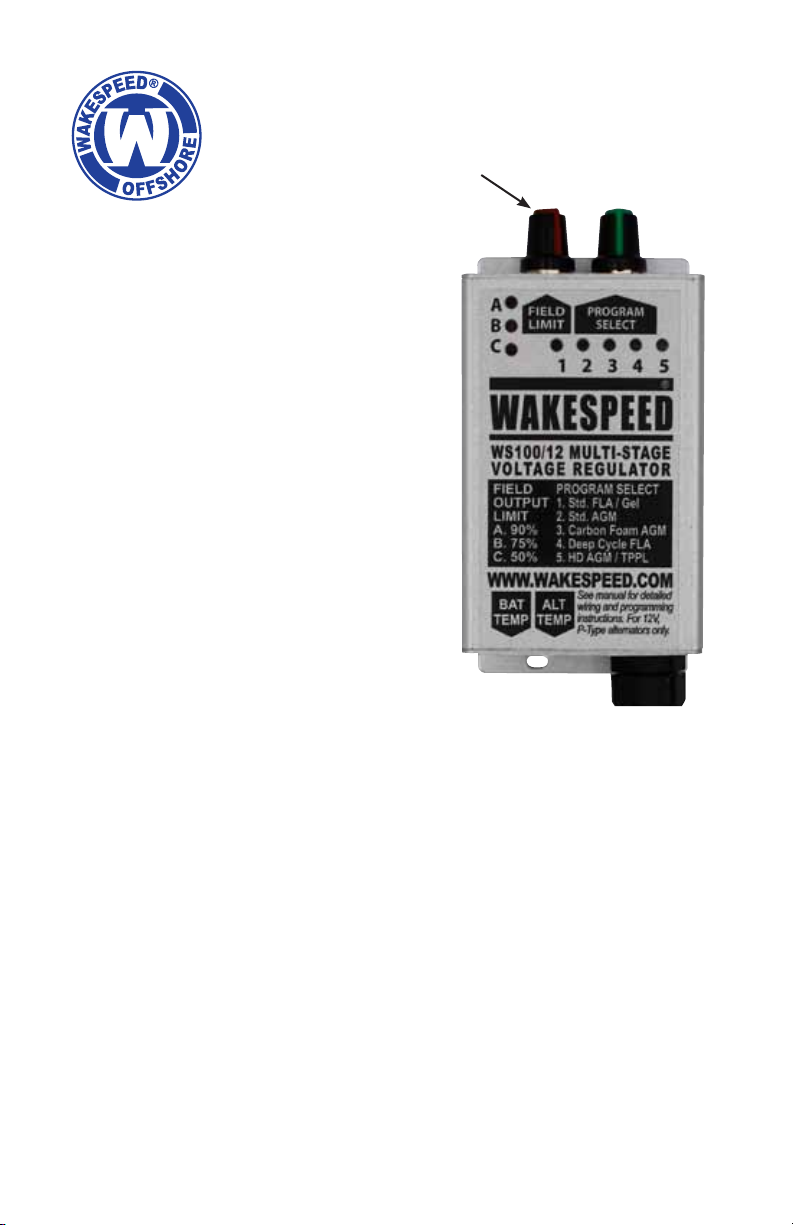

OPERATIONAL DISPLAY

During normal operation, the regulator will display a combination of green

lights in positions marked one through ve, indicating the progress of the

charge program. A combination of lights, as described below will indicate

charging activity status. Codes are as follows:

1. #1 Green Light — Indicates regulator is turned on.

2. #1 & #2 Green Lights — Indicates regulator is in bulk charge mode.

3. #1 & #3 Green Lights — Indicates regulator is in absorption charge

mode.

4. #1 & #4 Green Lights — Indicates regulator is in oat charge mode.

5. #5 Green Light — Indicates Dash Lamp mode is active. May be

active as a result of low system voltage, high system voltage, high

alternator temperature (>225°F) or high battery temperature (>125°F).