SAFETY

Warning for incorrect operation

or action that could have physical

injury or damage to the equipment

as a result.

Safety instructions

01. Never use this magnet before these

instructions have been read and understood.

02. Persons tted with a pacemaker or other

medical equipment should never use the

magnet without rst consulting a medical

specialist.

03. Never remove warning or instruction

plates from the magnet.

04. Always wear safety glasses, gloves,

protective footwear and a helmet.

05. Never stand or move under the load.

06. Never transport over or past people.

07. Never use the magnet as an aid to lifting,

supporting or transporting persons.

08. Warn bystanders when beginning to lift

the load.

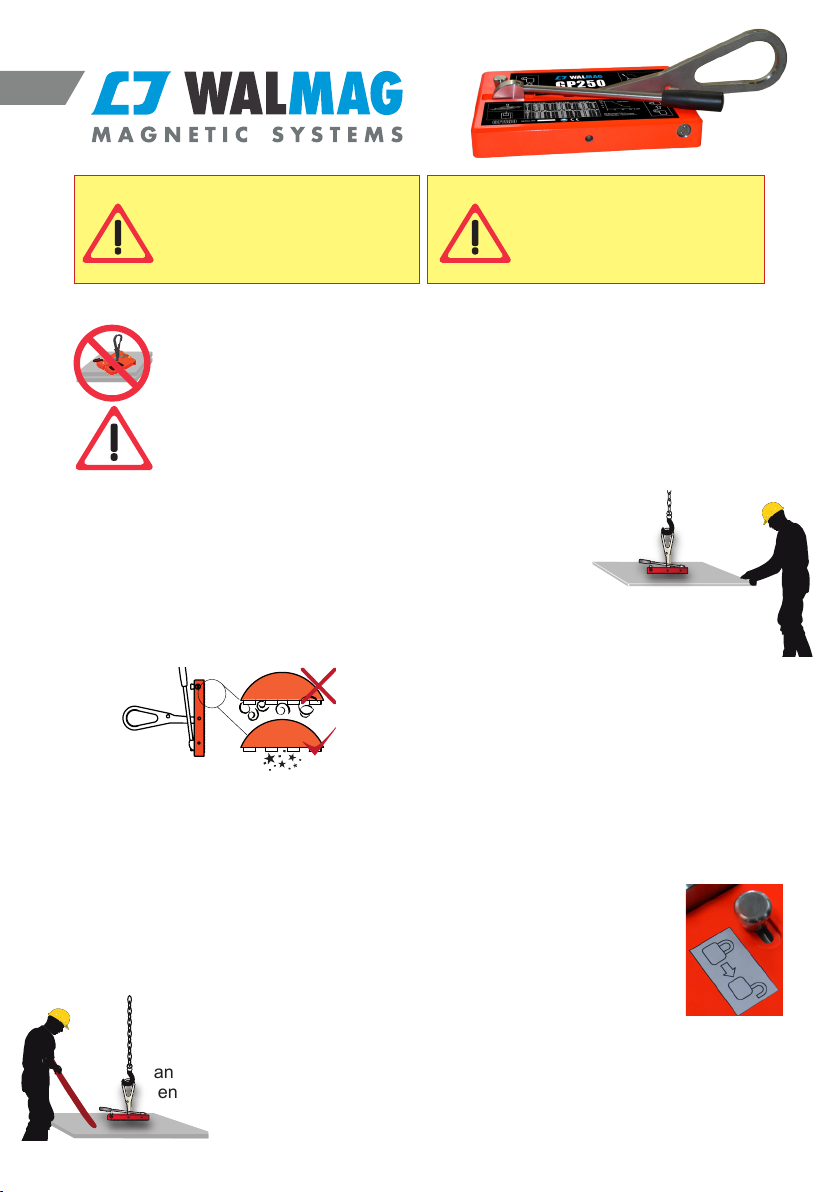

09. To prevent the hook from slipping out

of the eye hook always use a lifting hook

equipped with a safety latch.

10. Magnet is ON all the time. Risk of

involuntary attraction of steel objects:

a. in between handling operations

always keep the magnetic face away

from steel objects;

b. never hold or carry the magnet with

your ngers on the magnetic face;

11. Ensure that the weight and dimensions

of the load to be lifted do not exceed

the maximum permitted values.

12. Never use a damaged or poorly operating

magnet.

13. Never use the magnet with dirty pole

faces (metal chips, rust, scale, dust,…)

14. Only break the magnet off when the load

has been placed on a stable surface.

15. Never lift more than one work piece at

a time with this magnet.

16. Never leave a hoisted load unattended.

17. The temperature of the load or

the surroundings must never exceed 180°C.

18. Never lift a work pieces which are smaller

than pole surface (foot print)

DETERMINE THE

WORKLOAD LIMIT (WLL)

The workload limit of type GP250

Horizontal = 250 kg

Vertical = 80 kg

The workload limit may become less as a

result of:

01. Air gaps between the load and the

magnet, caused by paper, dirt, paint, burrs,

damage, surface roughness etc. either on

the load or the magnet.

02. Thin loads. The thinner the load, the

lower the lifting capacity.

03. Length and width of the load. Long, wide

parts that hang outside the magnet, resulting

in an air gap. This is called the peeling effect.

04. The load material type. In general it

applies that: high alloy percentage = low

lifting capacity.

05. Some alloys are even totally non-

magnetic (e.g. stainless steel 304). The

values in the table on page 4 apply to St.

37 (S 235 JR). For other materials the lifting

capacity will be reduced to the percentages

below:

EN

Workload limit for various materials

H V

Material % kg kg

St 37 [S 235 JR] 100 250 80

E 295 [St 52] 96 240 77

Cast steel 90 225 72

Stainless steel 430 F 50 125 40

Cast iron 45 112 36

Nickel 10 25 8

For other materials consult your supplier.

06. Maximum work load limit is obtained

while magnet is in fully horizontal position

during the transport.

2