Assembly Instructions –Hand Dosing Device WDVHP-0x-HG

Walther Systemtechnik GmbH –D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de –info@walther-2000.de

EC DECLARATION OF INCORPORATION ....................................................................................................................... 4

1INTRODUCTION ................................................................................................................................................. 5

1.1 TARGET GROUP OF THE ASSEMBLY INSTRUCTIONS ............................................................................................................ 5

1.2 LIST OF SIGNS AND SYMBOLS ....................................................................................................................................... 5

2SAFETY............................................................................................................................................................... 5

2.1 GENERAL INFORMATION ............................................................................................................................................. 5

2.2 DANGERS FROM RESIDUAL ENERGIES............................................................................................................................. 5

2.3 WARRANTY AND LIABILITY........................................................................................................................................... 5

2.4 CORRECT USE ........................................................................................................................................................... 6

2.5 INCORRECT USE ........................................................................................................................................................ 6

2.6 QUALIFICATION OF PERSONNEL .................................................................................................................................... 6

3TRANSPORT ....................................................................................................................................................... 7

3.1 PACKAGING .............................................................................................................................................................. 7

3.2 TASKS BEFORE TRANSPORT .......................................................................................................................................... 7

4DESCRIPTION OF FUNCTION .............................................................................................................................. 7

4.1 DESIGNATED USE OF INCOMPLETE DEVICE ...................................................................................................................... 7

4.2 TYPE LABEL OF INCOMPLETE DEVICE ............................................................................................................................. 7

4.3 FUNCTION................................................................................................................................................................ 7

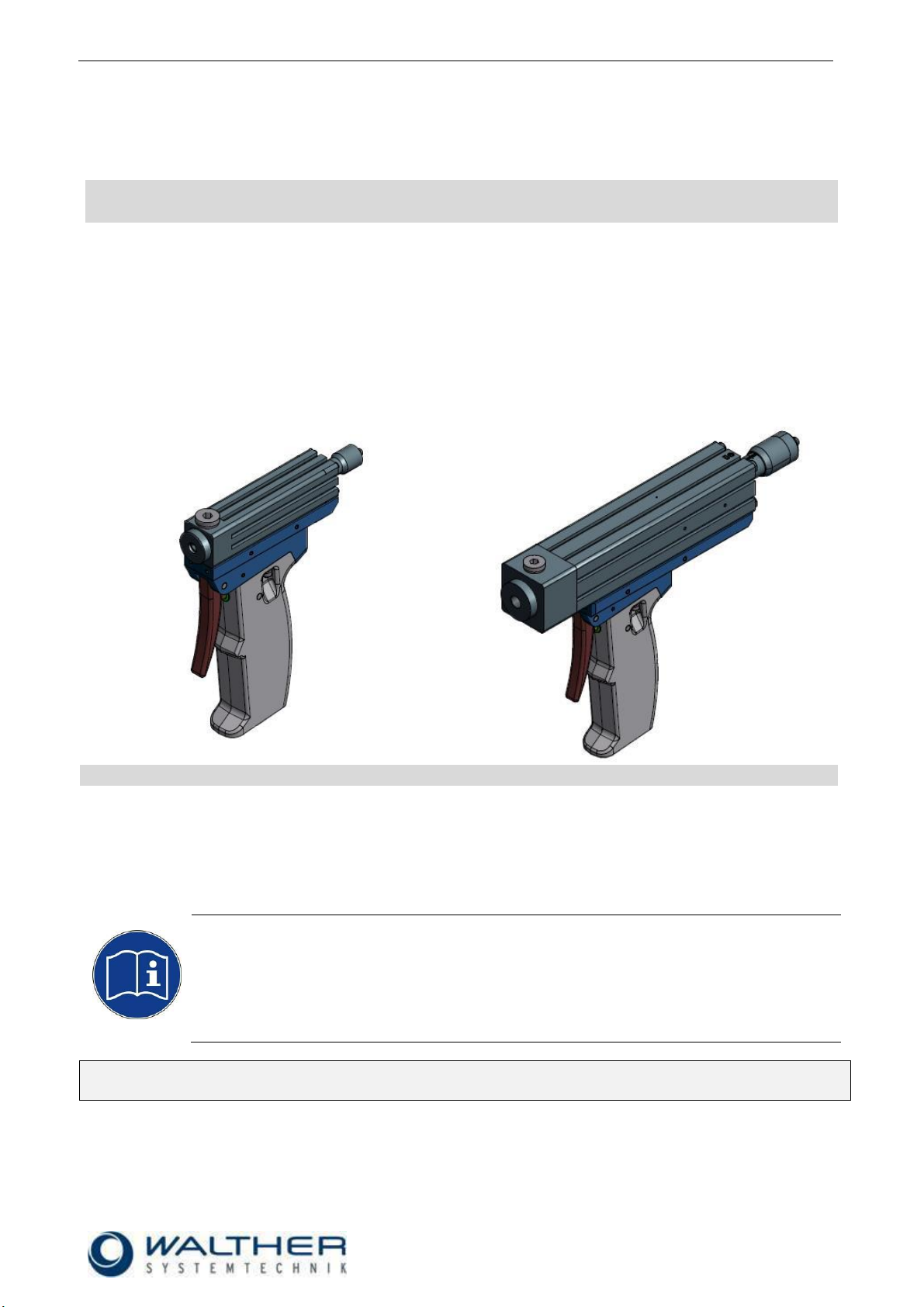

4.4 TOTAL VIEW /DESCRIPTION......................................................................................................................................... 8

4.5 CONNECTIONS .......................................................................................................................................................... 8

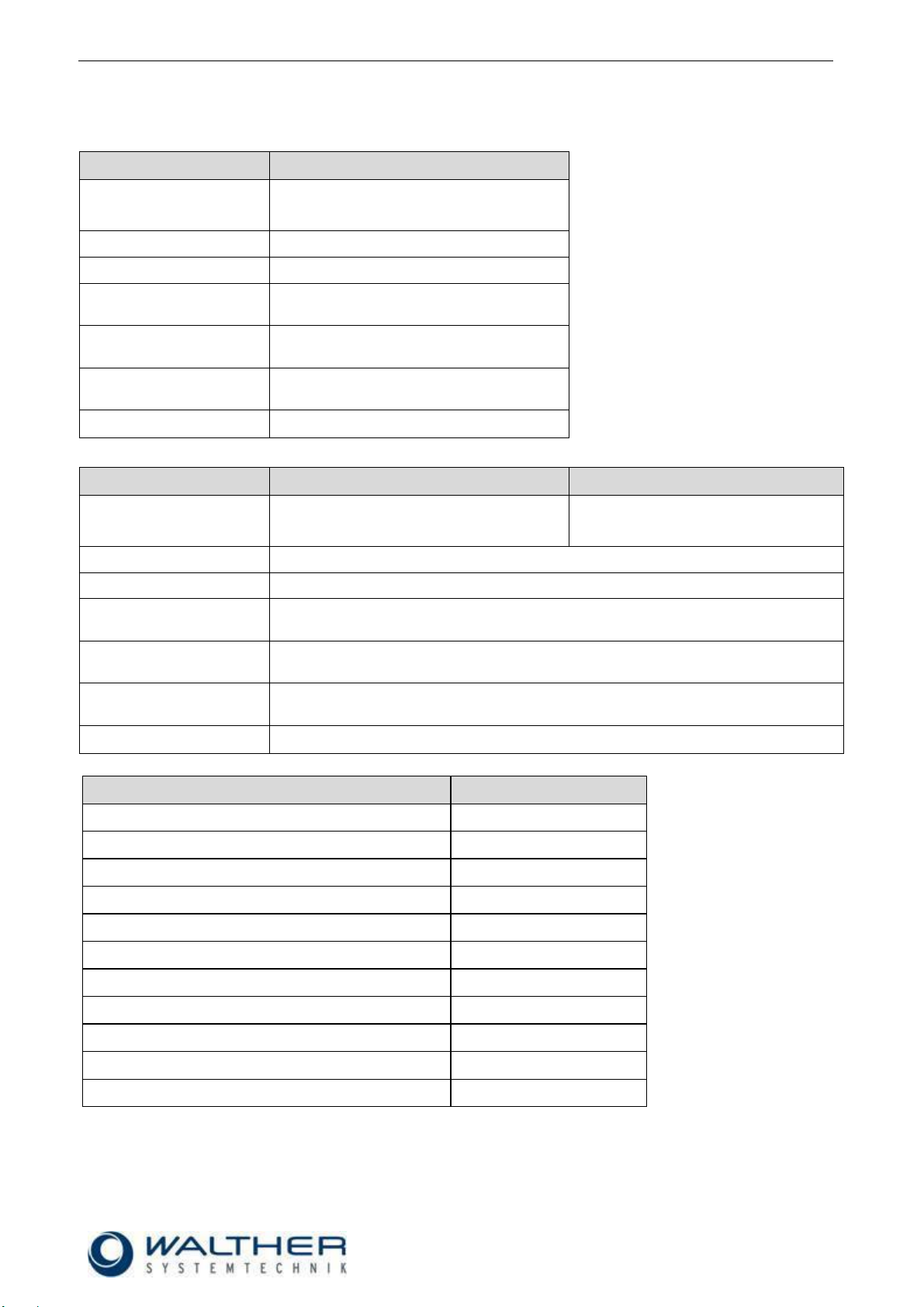

4.6 TECHNICAL DATA ....................................................................................................................................................... 9

5INITIAL START-UP ............................................................................................................................................. 10

5.1 MOUNTING AND INSTALLATION .................................................................................................................................. 10

5.2 ADJUSTING THE INCOMPLETE DEVICE .......................................................................................................................... 10

6OPERATION ..................................................................................................................................................... 11

6.1 GENERAL INFORMATION ........................................................................................................................................... 11

6.2 OPERATION INSTRUCTIONS /OPERATING CONDITIONS .................................................................................................... 11

6.3 OPERATING ELEMENTS ............................................................................................................................................. 11

7TAKING OUT OF SERVICE ................................................................................................................................. 12

7.1 SHORT INTERRUPTION .............................................................................................................................................. 12

7.2 LONG-TERM INTERRUPTION....................................................................................................................................... 12

7.3 SHUTDOWN OF DEVICE............................................................................................................................................. 12

8MAINTENANCE AND REPAIR ............................................................................................................................ 13

8.1 GENERAL INFORMATION ........................................................................................................................................... 13

8.2 ROUTINE TASKS....................................................................................................................................................... 13

8.3 SPARE PARTS .......................................................................................................................................................... 13

8.4 CUSTOMER SERVICE /SUPPORT.................................................................................................................................. 13

9TROUBLESHOOTING ........................................................................................................................................ 14

9.1 GENERAL INFORMATION ........................................................................................................................................... 14

9.2 MALFUNCTIONS ...................................................................................................................................................... 14

10 APPENDIX ........................................................................................................................................................ 15

10.1 DIMENSIONED AND SPARE PART DRAWING –DOSING VALVE WDVHP-02-HG .............................................................. 15

10.1.1 Spare Part List –Dosing Valve WDVHP-02-HG ..................................................................................... 16

10.2 DIMENSIONED AND SPARE PART DRAWING –DOSING VALVE WDVHP-03/04-HG.......................................................... 17

10.2.1 Spare Part List –Dosing Valve WDVHP-03-HG ..................................................................................... 18

10.2.2 Spare Part List –Dosing Valve WDVHP-04-HG ..................................................................................... 18

10.3 ACCESSORIES ..................................................................................................................................................... 19