Operating instruction and technical description EV tester type 1 and type 2 - 2.0

©Walther-Werke Ferdinand Walther GmbH Seite 9 von 12

Setting the rotary switch of the measuring device to the measuring range Ω(Ohm) activates the measuring

process. If there is no indication please check or replace the batteries of the measuring device.

Photos: Resistance measurement with connected cable and actuated pushbutton

With inserted plug, the nominal value 150 Ωshould be indicated. In this case, the pushbutton on the plug is

not pressed. By pressing the pushbutton on the plug, the nominal value 480 Ωshould be indicated. After

successful measurement, switch off the measuring device (turn rotary switch to OFF).

If other or no measured values are indicated, the plug and the relevant switch positions have to be checked.

Attention:

The integrated measuring device is for resistance measuring only and should therefore only be switched on

shortly for measuring the resistances (will result in a longer battery durability). Under no circumstances leave

it switched on during other test procedures with applied voltage.

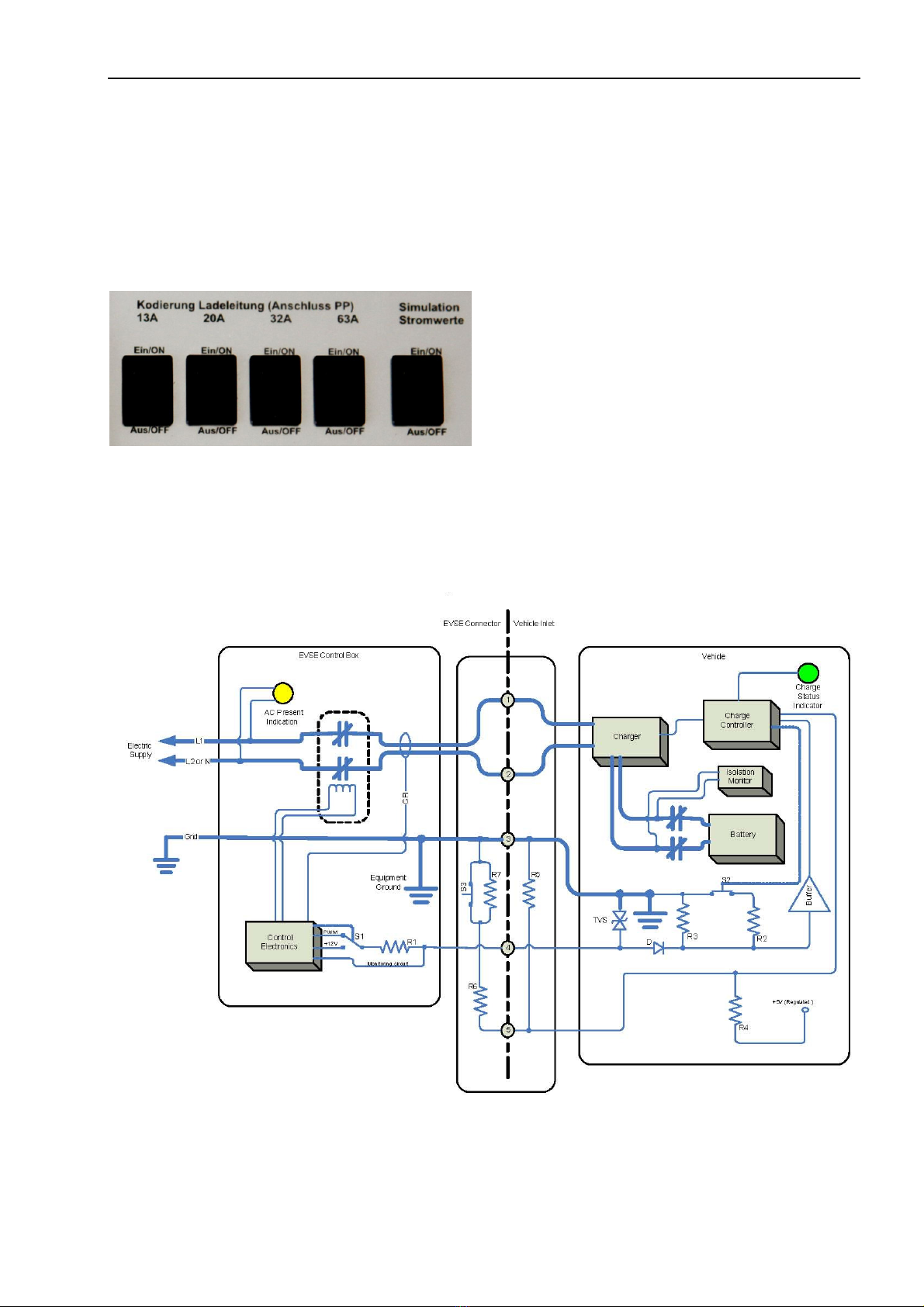

4.6 Checking the PE connection between PWM and vehicle

The PE EV switch is used to check the PE connection. In switch position Ein/ON the PE is connected, in

switch position Aus/OFF it is interrupted. Thus the connection between PE and CP on the vehicle side is

interrupted and the charging process should be switched off by the charging device. Now the charging device

should no longer react to operating the switches Status EV (signal CP) B, C or D.

4.7 Simulation of a fault by means of switchable fault current

To test the triggering of the RCD in case of error, a switchable leakage current (> 30 mA) is created. This

leakage current is conducted from L1 to PE via an integrated resistance (3,3 kΩ). The leakage current is

created by pressing the FI/RCD pushbutton shortly (switch position Ein/ON). The protective device inside the

charging infrastructure has to trigger immediately. In case of correct switching off the red LED flashes shortly

and the RCD triggers. The charging process should be interrupted directly.

Attention:

If the LED FI/RCD shines permanently while the pushbutton is pressed, release the pushbutton immediately.

Then the protective device FI/RCD respectively the wiring of the installation has to be checked.

In case of single-phase use of the charging infrastructure, care must be taken to ensure that L1 and N have

not been interchanged on the charging device, i.e. it must be possible that a leakage current can flow to PE.

(L1 = L and N = N). Only under these circumstances can the test be carried out correctly.