Installation

2023248 [Rev. 4 - en]/2018-05-04 Page 5 | 8

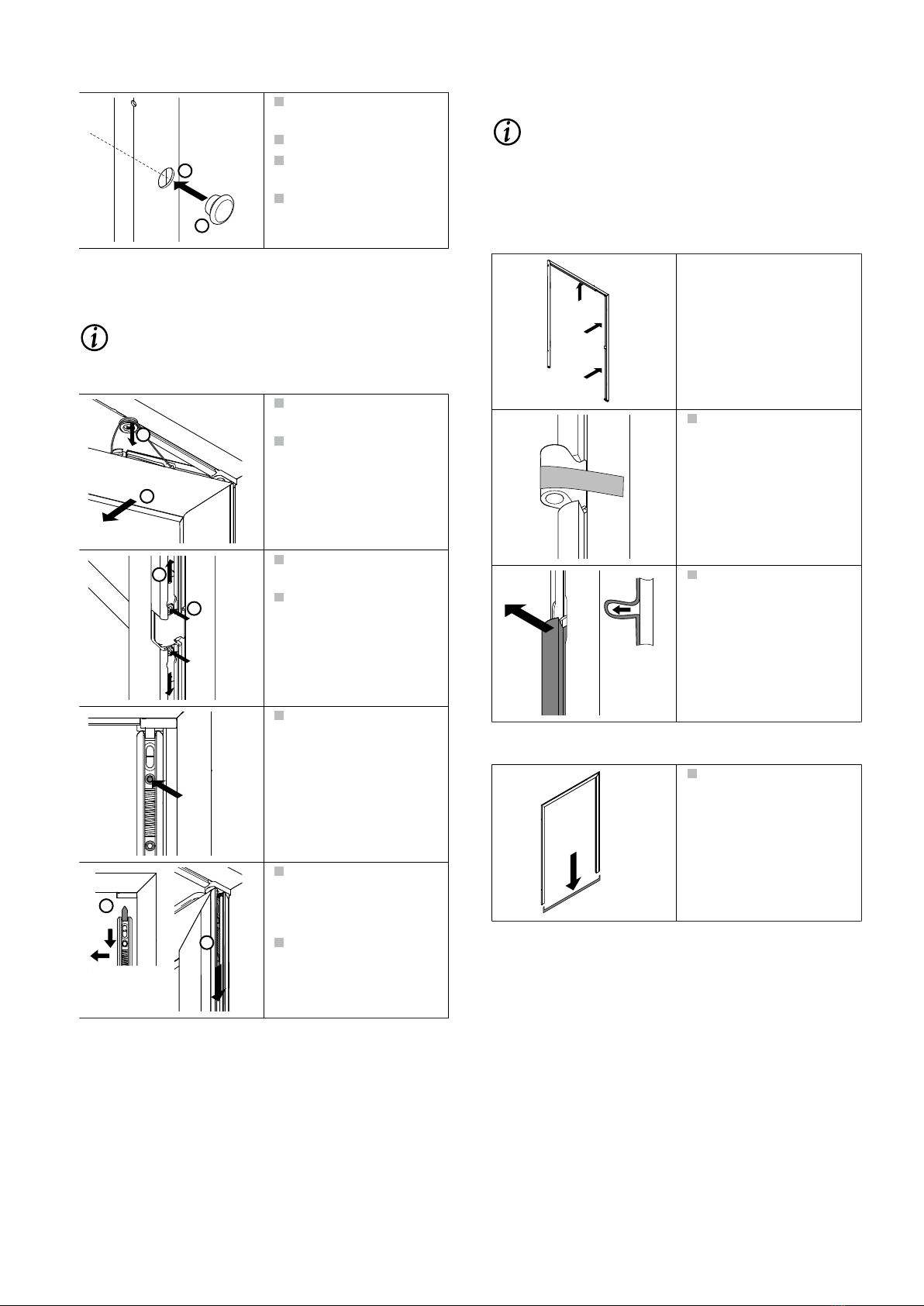

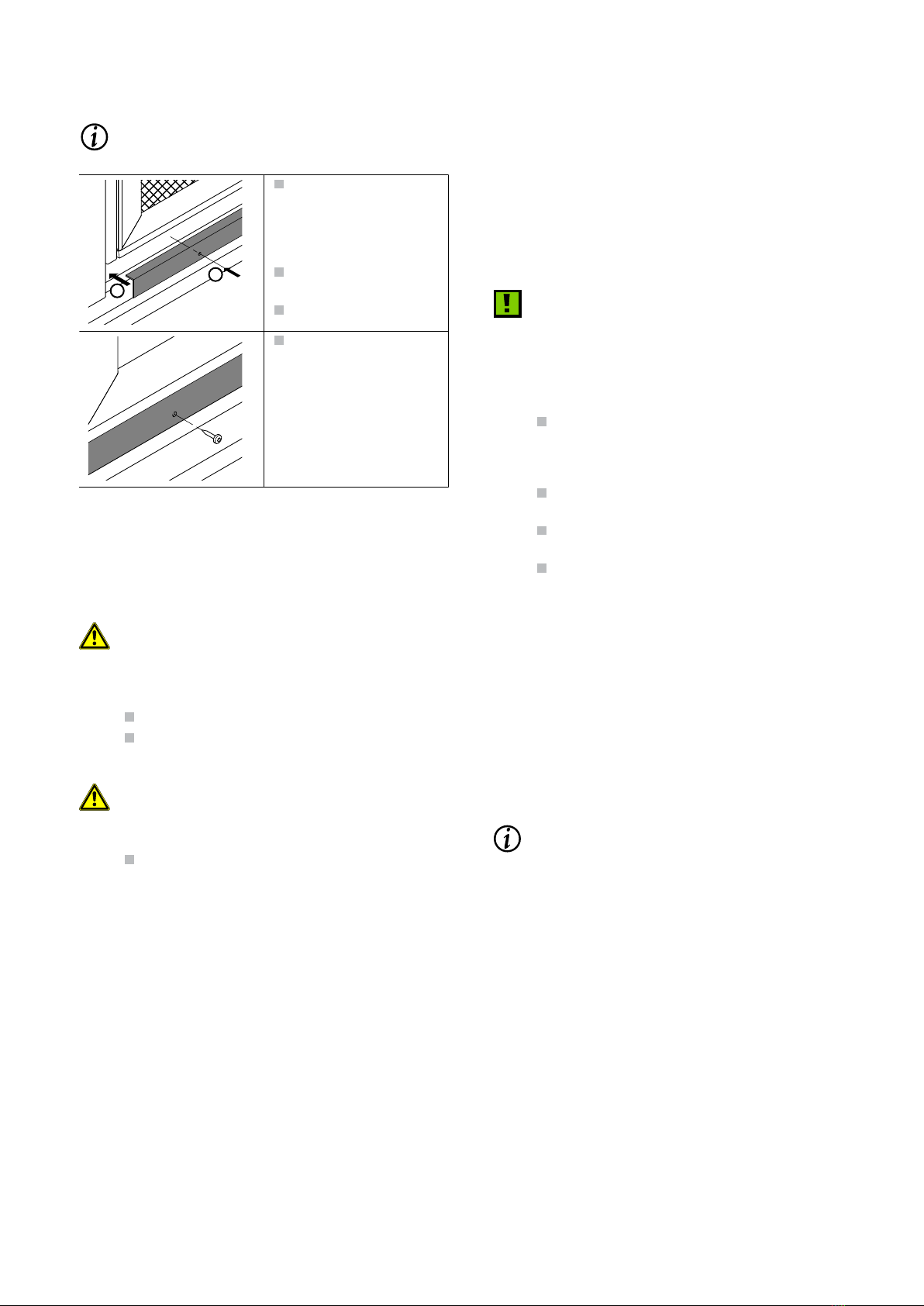

2.5 Installing the L-guide profile

INFO

Only required with P.50, P.51 and P.80.

Position the L-guide pro-

file below the swinging

door against the mount-

ing substructure and

align.

Transfer the drill hole

position.

Drill the fixing holes.

Attach the L-guide pro-

file.

3 Maintenance

Proper and regular cleaning and the use of original spare

parts only are essential for fault-free operation and a long

service life.

CAUTION

Risk of injury from falling from climbing aid!

Climbing aids (e.g. ladders, scaffolding etc.) may tip

over if improperly erected.

Position climbing aids on level and firm ground.

Do not rest climbing aids against the product.

CAUTION

Risk of injury from falling!

There is a risk of falling during maintenance work!

Take suitable, safe measures to prevent or stop a

fall!

3.1 Cleaning and care

Over time, a film of dirt will settle on the surfaces of

products due to environmental influences.

Due to the effects of solar radiation, this contamination may

become permanently adhered to the surface coating. These

factors reduce the value and, possibly, impair the function

of the product.

To contribute to a long service life of the product, the

surfaces should be cleaned regularly or at least once a

year.

In certain environments such as in industrial zones, close

to heavy traffic and in the vicinity of the sea (salty air), more

frequent cleaning may be necessary to protect against

surface damage.

Purpose of cleaning and care

The purpose of regular and proper cleaning and care is to

retain the value of the product and extend its service life.

The purpose of repeatedly cleaning the product is to retain

the well-maintained appearance of the building and product.

Result of cleaning

NOTICE

Product damage from incorrect cleaning!

Incorrect cleaning procedures may result in

damage to the product or product parts. Surfaces

and structures may be permanently altered (e.g.

scratches).

Do not use high pressure washers, steam

washers, abrasive sponges, abrasive cleansers,

or aggressive cleaning agents or solvents such

as alcohol or naphtha.

Do not use chlorinated cleaning agents on or

near the product.

Do not wash the insect screen gauze in a

washing machine or similar equipment.

Do not rub the fabric excessively with a hard

brush or sponge.

No claims for damage can be raised on the grounds of this

cleaning information, as the effectiveness depends on a

large number of factors that vary widely from case to case.

The effort required for cleaning and the cleaning results

depend on the degree of soiling. It will difficult or possible

to restore surfaces that have been exposed to the weather

and have not been cleaned over many years to their original

state.

General information on cleaning

Tip/recommendation

The WAREMA cleaning glove combined with

WAREMA cleaning agent concentrate for sun

shading products is ideal for properly cleaning the

surfaces.

The WAREMA cleaning agent can be used for metal

and plastic surfaces and is certified by the GRM

(Gütegemeinschaft Reinigung von Fassaden e.V.)

(certification no. 142, 242, 342, 442, 542).

To order, contact your WAREMA dealer.